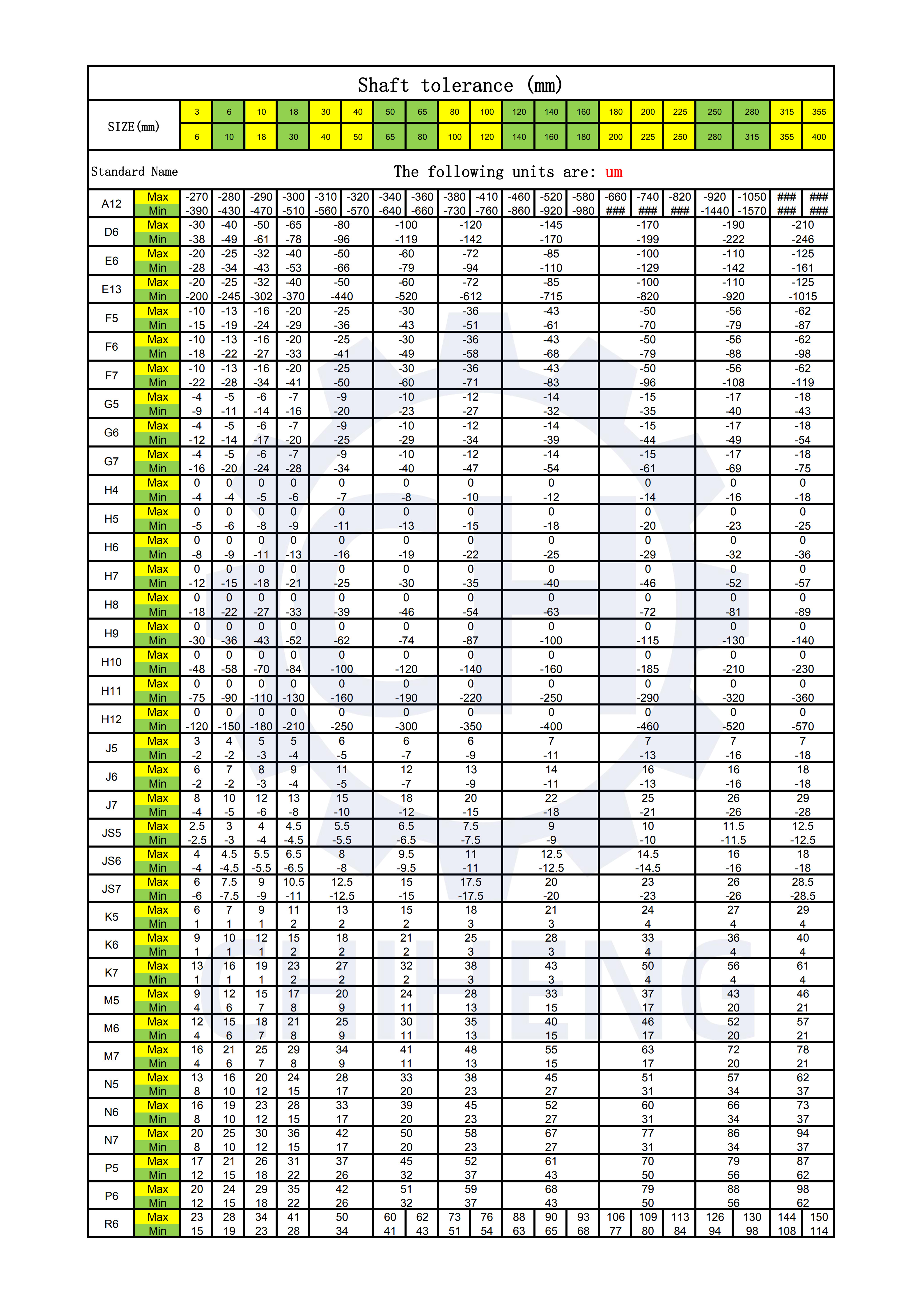

Shaft Tolerances - ISO 286 Standard

Axis Tolerance: The Precision Essence of CNC Machining Processes

In modern industrial manufacturing, CNC machining technology has become an indispensable part. CNC machine tools can manufacture various components with high precision, ranging from automotive engines to aircraft parts. However, to ensure the compatibility and performance stability among these components, a key factor is axis tolerance. This article will explore the critical role of axis tolerance in various CNC machining processes and the importance of tolerance accuracy.

I. The Concept of Axis Tolerance

Axis tolerance is a critical concept in engineering design, referring to the maximum allowable deviation between the axis of a component during its manufacturing process and its designed axis. This deviation is typically expressed in tolerance values, such as 0.01 millimeters or 0.001 inches. Axis tolerance determines the geometric accuracy of components, directly impacting the performance and reliability of the final product.

Shaft Tolerance (ISO 286-2) —— Download

II. CNC Machining Processes and Axis Tolerance

Milling and Turning

In CNC milling and turning processes, axis tolerance is a crucial factor in ensuring the precision of component dimensions and shapes. The CNC system of the machine tool must be able to control the position and movement of the cutting tool to keep the cutting axis on the workpiece within the specified tolerance range. Improper control of axis tolerance can lead to issues such as inconsistent dimensions, rough surfaces, or inaccurate shapes in the parts.Drilling and Grinding

In drilling and grinding processes, axis tolerance is equally vital. Precise hole diameters and surface quality require high-precision control of axis tolerance. CNC machine tools must be capable of creating holes or surfaces with the specified axis line on the workpiece to meet engineering requirements.Lathes and Grinders

In lathes and grinders, axis tolerance plays a critical role as well. These processes require precise control of workpiece rotation and movement to ensure that the geometric shape of the component matches the design specifications. Precise control of axis tolerance is key to producing high-quality bearings, gears, and transmission components.III. The Importance of Tolerance Accuracy

Product Performance

The precise control of axis tolerance directly affects product performance. If the tolerance is too large, components may not assemble correctly, leading to functional issues or decreased performance. Conversely, if the tolerance is too small, manufacturing costs may increase without necessarily improving performance.Interchangeability

One crucial role of axis tolerance is ensuring that components produced by different manufacturers can be interchangeable. This is essential for maintenance and servicing, especially in large-scale engineering projects. Inconsistent tolerances between components can make repairs and replacements difficult and costly.Quality Control

Tolerance accuracy is a critical component of quality control. By ensuring that each component falls within the specified axis tolerance range, manufacturers can enhance product consistency and reliability. This helps reduce the risk of product defects and recalls.In CNC machining processes, axis tolerance is a key factor in ensuring product quality and performance. Precise tolerance control can guarantee the geometric accuracy of components, enhance interchangeability, reduce maintenance costs, and contribute to quality control. Therefore, manufacturers and engineers should always consider axis tolerance as the central concept in CNC machining processes to ensure the production of high-quality, high-performance products.