I work with 316L stainless steel regularly on CNC milling projects for the UK market, and it’s worth starting with what makes this grade special and why finishing it to a mirror polish is not straightforward.

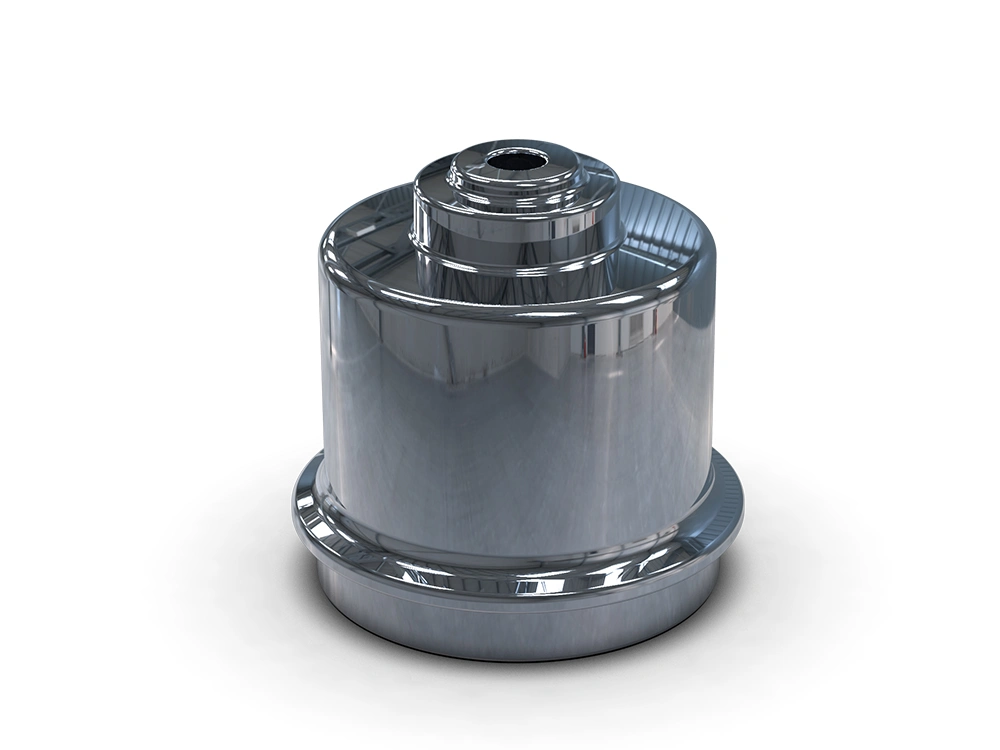

Here’s one of the projects. A UK-based medical device manufacturer required a 316L stainless steel material for its critical surgical instrument components, along with a mirror-polished finish achieving a Ra value of ≤0.1 μm. This type of surface treatment is crucial for reducing bacterial adhesion, enhancing corrosion resistance, and meeting the ISO 13485 standard for the UK medical industry. The core challenge of this project was to overcome the high hardness and work-hardening characteristics of 316L stainless steel while preventing dimensional deviations caused by thermal deformation.

The company, who manufactures minimally invasive surgical instruments, required the processing of complex-geometry laparoscopy components with a tolerance of ±0.01 mm and a surface roughness that met optical reflectivity standards. 316L stainless steel was the material of choice due to its excellent biocompatibility and resistance to corrosion from bodily fluids. However, the material’s 2-3% molybdenum content exacerbated its tendency for work-hardening, posing stringent demands on both tooling and processing techniques.

The primary difficulties included:

To address the challenges above, we implemented a systematic approach:

Post-processing involved a four-stage progressive polishing method:

Quality Control:

We successfully met the client’s stringent requirements, achieving significant improvements in key performance indicators. The results are summarized below:

| Indicator | Before Improvement | After Improvement |

| Surface Roughness (Ra) | 1.2 μm | 0.08 μm |

| Tool Life | 15 minutes | 120 minutes |

| Delivery Time | 4 weeks | 2.5 weeks |

The client confirmed that the product’s reflectivity reached 90% (exceeding the required 85%), and the corrosion test passed the ISO 9227 standard for a 500-hour salt spray test. The project was delivered two weeks ahead of schedule, and the client commented that the “surface quality surpassed that of similar German-made products,” leading to an additional order of 200 pieces.

This project validated three of our core competencies:

For international clients with high-end needs, we offer:

Whether you require mirror-finished stainless steel components that comply with ASTM A480 standards, or are seeking a machining solution to achieve UKCA certification, our engineering team is ready to provide a customized solution for you.

You can send us any questions to get any information you would like to know, and we will respond to you in extremely short time.