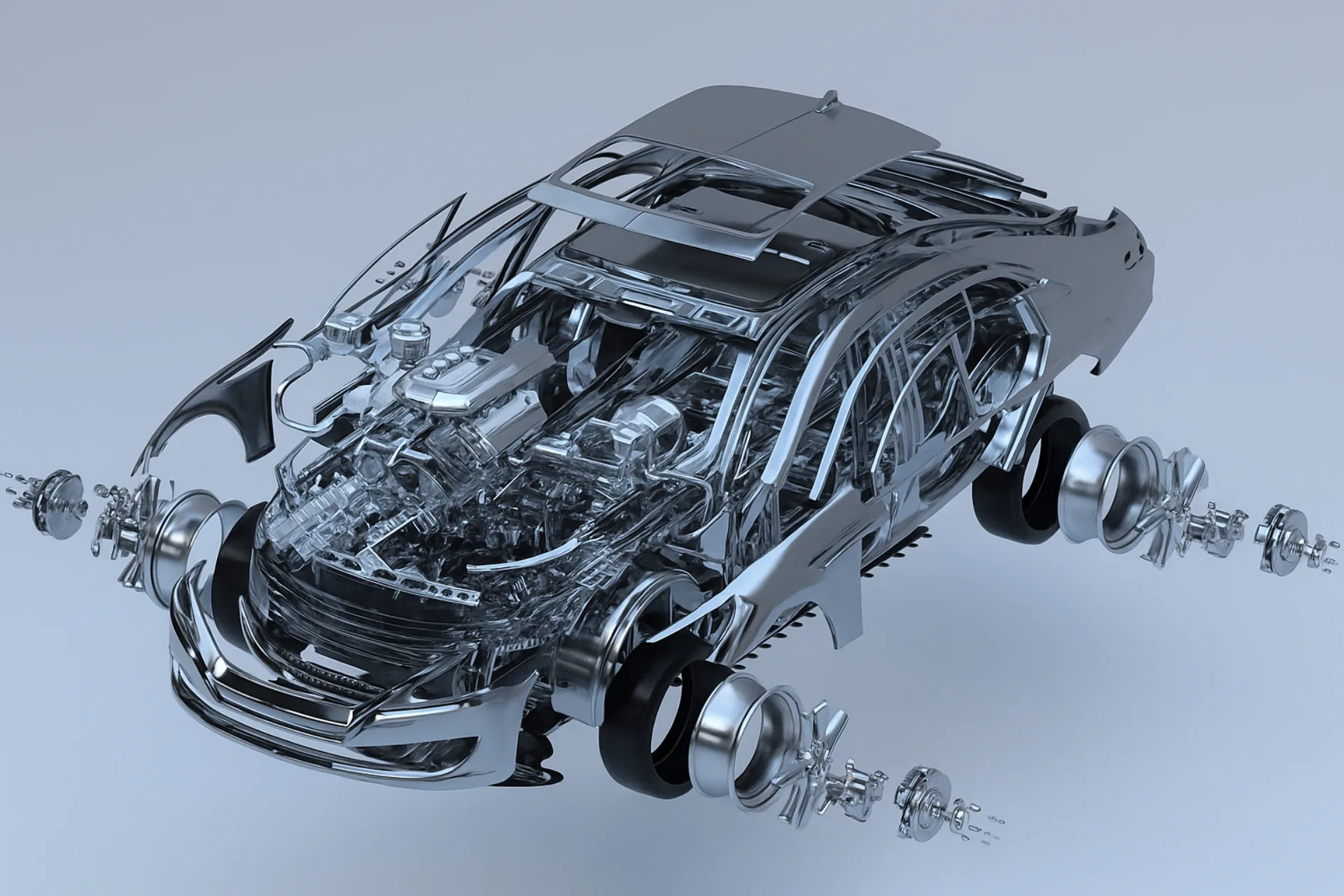

Fast & Precision & Complexity

Explore our capabilies to achieve your precision machining parts projects.

Our custom machined parts service stands out with a 3000㎡ factory, 80+ skilled engineers, and over 50 advanced CNC machines (3-axis to 5-axis). We specialize in low MOQ (starting at 1 piece) for agile prototyping and seamless transitions to high-volume manufacturing.

High Precision and Consistency

Achieve ±0.005mm tolerances for mission-critical components in various industries.

One-stop CNC Factory & Measuring Center

Equipped with 100+ CNC Machines and QC equipment & 80+ Skilled Supporting Machinist and Stuff.

Material and Finish Expertise

Over 50+ metal alloys and plastics, premium certified for RoHS and ISO 9001 standards.

Fast and Reliable Delivery

Enjoy fast manufacturing and cost-effective shipping rates for both small and large orders.

Welcome to Chiheng Hardware, your trusted partner for custom machined parts service delivering high-precision CNC machining solutions.

Whether you’re prototyping innovative designs or scaling production runs, our state-of-the-art facility ensures custom machined parts that meet your exact specifications – on time, every time.

With tolerances as tight as ±0.005mm, we handle metals like aluminum, stainless steel, and titanium, plus engineering plastics like PEEK and ABS.

Get an instant quote and transform your ideas into reality!

Elevate your projects with our custom machined parts service in metals. From aluminum 6061 for lightweight structures to stainless steel 316 for corrosion resistance, we machine components that withstand the toughest environments.

Applications: Gears, housings, and fixtures for industrial automation.

Capabilities: High-speed milling up to 20,000 RPM for intricate details.

Our ISO 9001:2015 certified facility maintains complete traceability throughout the manufacturing process, ensuring consistent quality for aerospace, medical, and precision industrial applications.

Precision meets versatility in our custom machined parts service for plastics. Ideal for low-friction, high-impact parts like Delrin bushings or nylon prototypes.

Applications: Medical devices, electronics enclosures, and consumer products.

Capabilities: Tight tolerances without warping, plus post-machining polishing.

We have an entire manufacturing process for all product mass production, professional engineers team and the best CNC machining, thus we can control the quality and the lead time for your products for production

Partner with Chiheng for a custom machined parts service that exceeds expectations. No project is too small or complex – from rapid prototypes to full assemblies.

| Machine | Quantity | Brand | Max Part Size |

| 3-Axis CNC Machine | 50 | FANUC-A-D14MIA | 1500×800mm |

| 4-Axis CNC Machine | 10 | – | 600x1200mm |

| CNC Lathe Machine | 35 | Tsugami | 300x1200mm |

| Lathe Mill Machine | 3 | Tsugami | 300x1200mm |

| CNC Swiss Type Automatic Lathe | 5 | Tsugami | 30x500mm |

Go beyond basic finishes with our comprehensive surface treatment services. Batch and low-volume production to accommodate various project sizes.

CNC prototyping belongs to the category of subtractive manufacturing, delivering outstanding accuracy and material flexibility while ensuring durability. This makes it highly suitable for producing prototypes that not only resemble the final design but also perform under real-world conditions.

By utilizing machines such as CNC turning centers and milling equipment, along with a range of specialized cutting tools, raw stock is shaped with remarkable precision based on digital CAD data.

Chiheng’s dimensional tolerances can reach as fine as ±0.005 mm or even better, which is critical when components must fit together seamlessly or undergo rigorous functional validation.

In contrast with additive approaches like 3D printing, CNC machining often involves higher costs and longer lead times when handling one-off designs with intricate, organic geometries. However, it stands out when creating working prototypes from metals and advanced plastics that share the same mechanical behavior as production-grade parts.

While 3D printing is generally preferred for rapid and inexpensive concept models during the early development stage, CNC machining becomes increasingly advantageous once projects move toward limited production runs. This enables a smooth progression from initial prototype to market-ready component.

All industrial you can get CNC parts from our service, we are the best choice for you!

About CHIHENG machining parts technology and news for your to know more about us

What Is Tight Tolerance in CNC Turning? A Guide to Precision Machining Cylindrical Parts From aerospace components to medical devices—precision is not merely a requirement; it is the definition of functionality. For procurement officers, sourcing

Custom Electroplating Solutions for Corrosion Resistance: Processes, Benefits, and Finishes Like Zinc, Nickel, and Chrome “Looking for Turned Parts Electroplating Finishing Services?” Here top-quality turned parts electroplating solutions tailored for durability and precision. Our guide

I work with 316L stainless steel regularly on CNC milling projects for the UK market, and it’s worth starting with what makes this grade special and why finishing it to a mirror polish is not straightforward.

Here’s one of the projects. A UK-based medical device manufacturer required a 316L stainless steel material for its critical surgical instrument components, along with a mirror-polished finish achieving a Ra value of ≤0.1 μm. This type of surface treatment is crucial for reducing bacterial adhesion, enhancing corrosion resistance, and meeting the ISO 13485 standard for the UK medical industry. The core challenge of this project was to overcome the high hardness and work-hardening characteristics of 316L stainless steel while preventing dimensional deviations caused by thermal deformation.

Start your projects today

You can send us any questions to get any information you would like to know, and we will respond to you in extremely short time.