| Material | ABS |

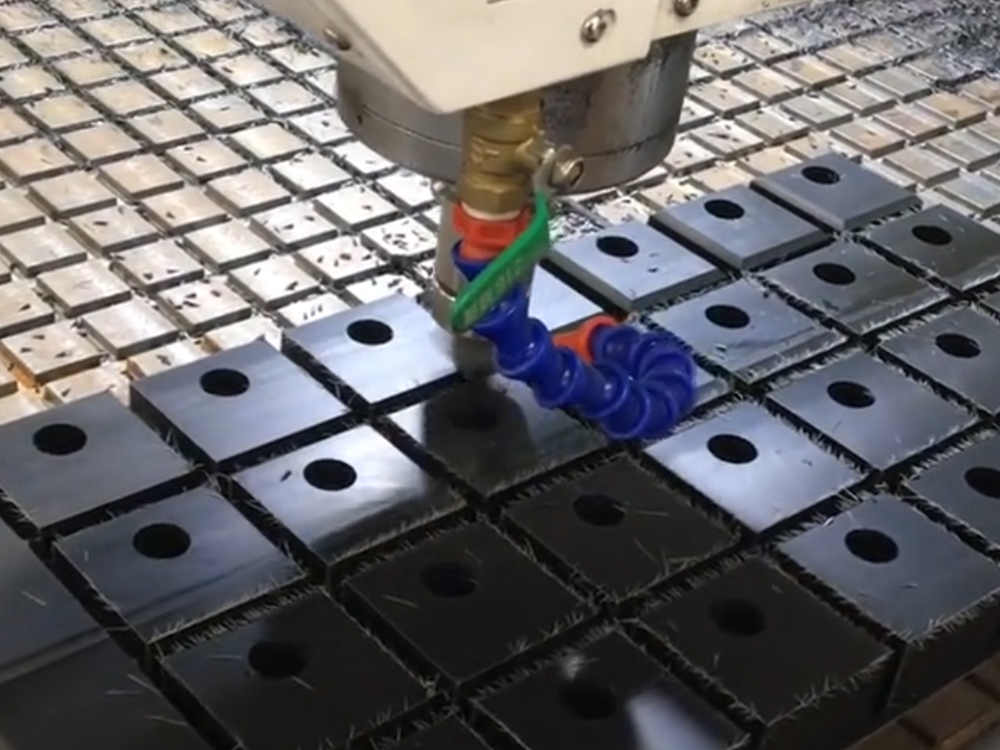

| Processing | CNC Turning |

| Surface Finish | Coating, Gloss Polishing, Electroplating |

| Application | Valves and fittings |

Our shop specializes in high-precision CNC turning and milling of ABS (Acrylonitrile Butadiene Styrene) to produce complex parts with threaded features for valve and fitting applications. Whether it’s a custom thread profile or a tight tolerance interface, we ensure every ABS turned part meets exact specifications for performance and durability.

| Material Type | Tensile Strength (MPa) | Impact Strength (kJ/m²) | Heat Distortion Temperature (°C) |

|---|---|---|---|

| ABS General Purpose | 40 | 70 | 95 |

| ABS (30% Glass-Filled) | 85 | 90 | 105 |

| ABS High Impact | 55 | 100 | 90 |

| ABS Natural Color | 45 | 80 | 100 |

| ABS Heat Resistant | 70 | 60 | 120 |

High impact resistance

Good toughness and rigidity

Excellent dimensional stability

Good electrical insulation

Resistance to abrasion and chemicals

Industrial machinery housings and brackets

Fluid control valves and fittings

Electronic device enclosures and protective cases

ABS offers several unique properties that make it an excellent choice for threaded components in valves and fittings:

Excellent Dimensional Stability

ABS maintains tight tolerances during and after machining, which is critical for threaded connections that must fit precisely and seal effectively.

Good Impact and Chemical Resistance

This makes ABS components durable in demanding industrial environments where fittings and valves may be exposed to mechanical stress or mild chemicals.

Smooth Surface Finish

Our CNC processes deliver clean, burr-free thread profiles with consistent surface finishes—ideal for sealing surfaces or O-ring interfaces.

Cost-Effective Alternative to Metals

ABS machined parts are typically lighter and more affordable than metal alternatives, especially in short production runs or prototyping scenarios.

We utilize state-of-the-art CNC lathes and turning centers capable of producing both internal and external threads on ABS parts. Threading options include:

Metric and Imperial Threads

Custom sizes and standard profiles such as BSP, NPT, UNC/UNF, and ISO threads.

Single or Multi-Start Threads

For quick engagement and specialized flow control applications.

Threaded Inserts and Post-Machining Assembly

We offer integration of metal inserts or sealing features for added durability or compatibility with other system components.

ABS machined parts with threads are widely used in:

Water and Air Control Systems

Lightweight and corrosion-resistant parts for regulating flow in residential, commercial, or industrial systems.

Custom Connectors and Couplings

Ideal for low-pressure applications where plastic components can replace heavier or costlier metal fittings.

Prototype Valve Bodies and Enclosures

Fast turnaround on custom designs for testing and pre-production runs.

You can send us any questions to get any information you would like to know, and we will respond to you in extremely short time.