| Material | PEEK |

| Processing | CNC Milling |

| Surface Treatment | Polishing, Coating |

| Application | Orthopedic implants,Dental instruments,Surgical tools,Prosthetic components |

Medical-grade PEEK (Polyether ether ketone) is one of the most advanced materials for high-performance implants, surgical instruments, and other precision components. But here’s the thing: machining PEEK, especially for medical parts, isn’t as straightforward as working with metals or common plastics.

| Category | Features | Benefits |

| Chemical and Physical Properties | High heat resistance (up to 480°F/250°C), excellent wear and abrasion resistance, low moisture absorption, radiolucency | Suitable for long-term implantation and intensive-use surgical tools, stable in humid/in-body environments, compatible with X-ray/CT/MRI imaging |

| Biocompatibility and Sterilization Resistance | Biocompatible (meets FDA and ISO 10993 standards), withstands autoclave steam, gamma radiation, and ethylene oxide (EtO) treatments | Safe for human use, reliable for reusable medical devices due to repeated sterilization capability |

| Mechanical Strength and Durability | Tensile strength up to 14,000 psi, high fatigue resistance, exceptional dimensional stability | Comparable to metals while lighter, ideal for load-bearing applications like prosthetics, spinal implants, and orthopedic devices |

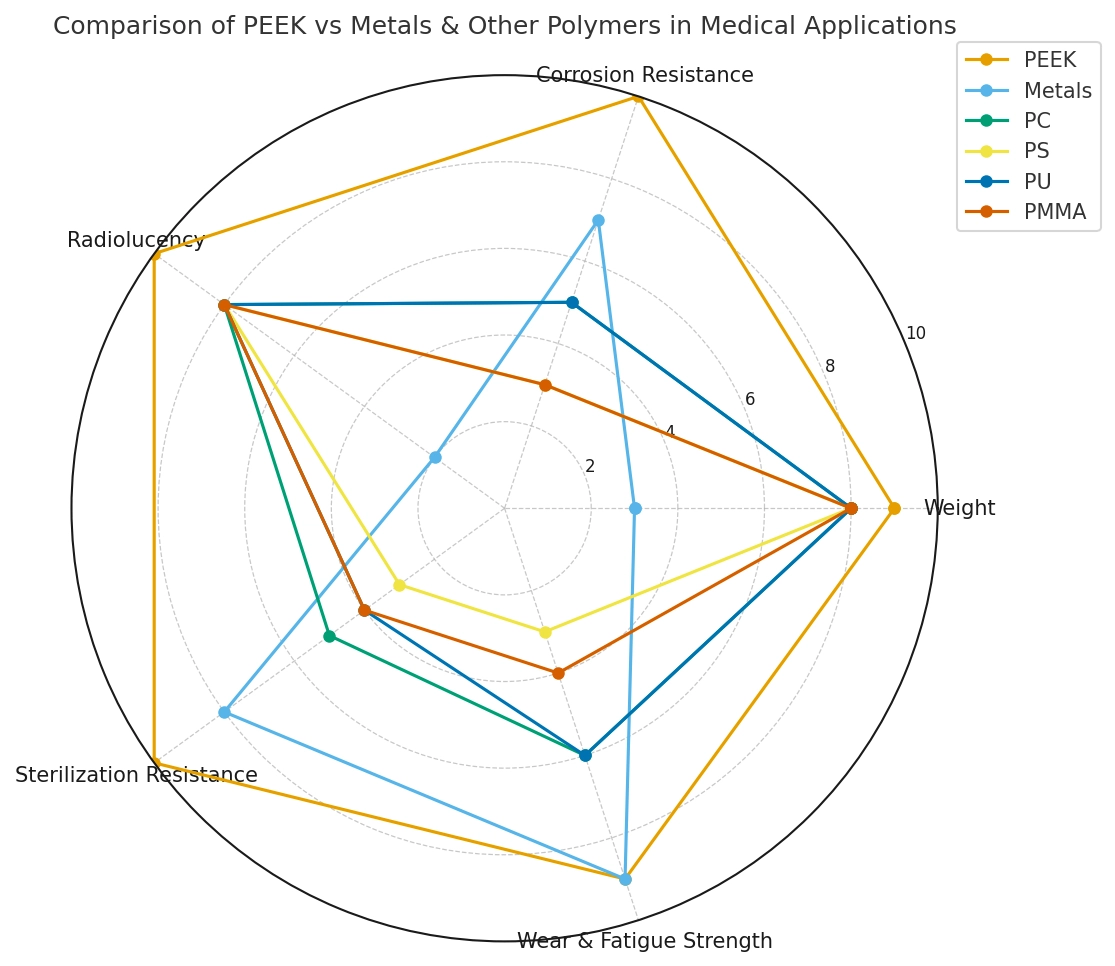

| Material | Weight | Corrosion Resistance | Radiolucency | Sterilization Resistance | Wear & Fatigue Strength |

| PEEK (Polyether ether ketone) | Light (~1.3 g/cm³, about 1/5 of metals) | Excellent, highly resistant to acids, bases, and body fluids | Excellent, fully radiolucent, no imaging artifacts in X-ray, CT, or MRI | Excellent, resistant to steam, gamma, and ethylene oxide sterilization | Excellent, close to bone elastic modulus, superior fatigue resistance, high wear resistance |

| Metals (Titanium alloys, Stainless steel, Cobalt-Chromium) | Heavy (~4.5–8 g/cm³) | Titanium alloys: good; Stainless steel: moderate; Cobalt-Chromium: excellent | Poor, cause significant artifacts in X-ray/MRI | Generally good for steam sterilization, but may corrode over time | Very strong but much higher elastic modulus than bone, leading to stress shielding; high wear resistance but fatigue fracture risk |

| PC (Polycarbonate) | Light (~1.2 g/cm³) | Moderate, poor hydrolysis resistance, degrades in body fluids | Good, radiolucent | Moderate, resistant to ethylene oxide; degrades under steam sterilization | Moderate, good toughness but limited fatigue and wear resistance |

| PS (Polystyrene) | Light (~1.05 g/cm³) | Poor, limited chemical resistance, easily damaged by organic solvents | Good, radiolucent | Poor, low heat resistance, limited to ethylene oxide sterilization | Poor, brittle, low fatigue and wear resistance |

| PU (Polyurethane) | Light (~1.2 g/cm³) | Moderate, some hydrolysis resistance but degrades in body fluids unless modified | Good, radiolucent | Moderate, low heat resistance, typically sterilized with low-temperature methods | Good toughness and wear resistance, but limited fatigue life (aging and hardening over time) |

| PMMA (Polymethyl methacrylate) | Light (~1.2 g/cm³) | Poor, limited chemical resistance, prone to cracking | Good, widely used in intraocular lenses and bone cement | Moderate, poor heat resistance, usually sterilized by ethylene oxide or low temperature | Poor, brittle with low fatigue and wear resistance |

Over the past few years, we’ve worked with several global medical device manufacturers to produce high-precision PEEK components for surgical instruments, implants, and diagnostic equipment. Each project came with strict requirements for tolerances, surface finish, and cleanliness.

One example was a custom CNC milling project for a spinal implant. The client needed complex geometries with tight ±0.01 mm tolerances, plus a flawless surface finish that would meet medical-grade inspection standards. We adapted our CNC milling process, fine-tuned cutting parameters, and used medical-grade tooling to eliminate burrs and avoid thermal deformation. The final parts passed all dimensional checks.

For another project, an UK-based company needed lightweight, sterilizable PEEK handles for surgical tools. The main challenge was maintaining dimensional stability after repeated autoclave cycles. We selected the proper machining strategy and end up being verified results through in-house thermal cycling tests after sample delivery.

In both cases, we provided:

These projects show how our experience with medical-grade PEEK machining helps global clients get compliant, reliable, and ready-to-use components without compromise.

CMM (Coordinate Measuring Machine) checks complex geometries for precision.

Laser scanning captures full 3D profiles to verify even the smallest details.

High-accuracy gauges confirm critical dimensions stay within microns.

We measure surface roughness to ensure no burrs or irregularities that could affect patient safety.

Polished or ultra-smooth finishes get inspected under magnification to meet surgical-grade requirements.

Machined PEEK medical components undergo testing to ensure the process hasn’t altered their ISO 10993 or FDA-approved biocompatibility properties.

All cleaning is done in controlled environments to avoid contamination.

You can send us any questions to get any information you would like to know, and we will respond to you in extremely short time.