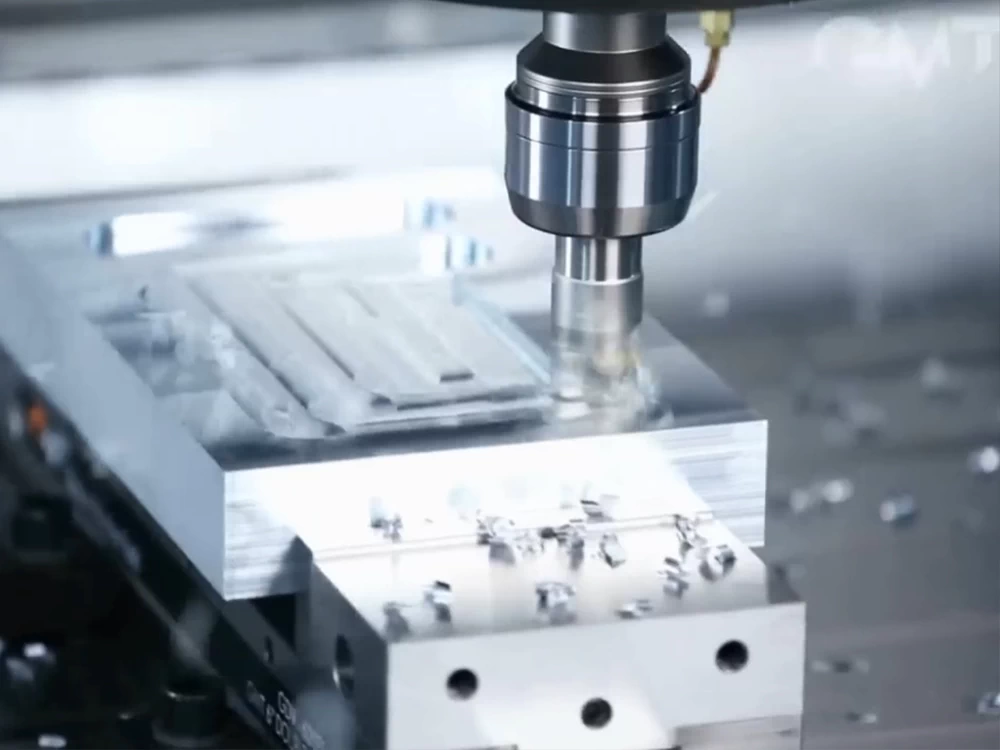

3 Axis Milling

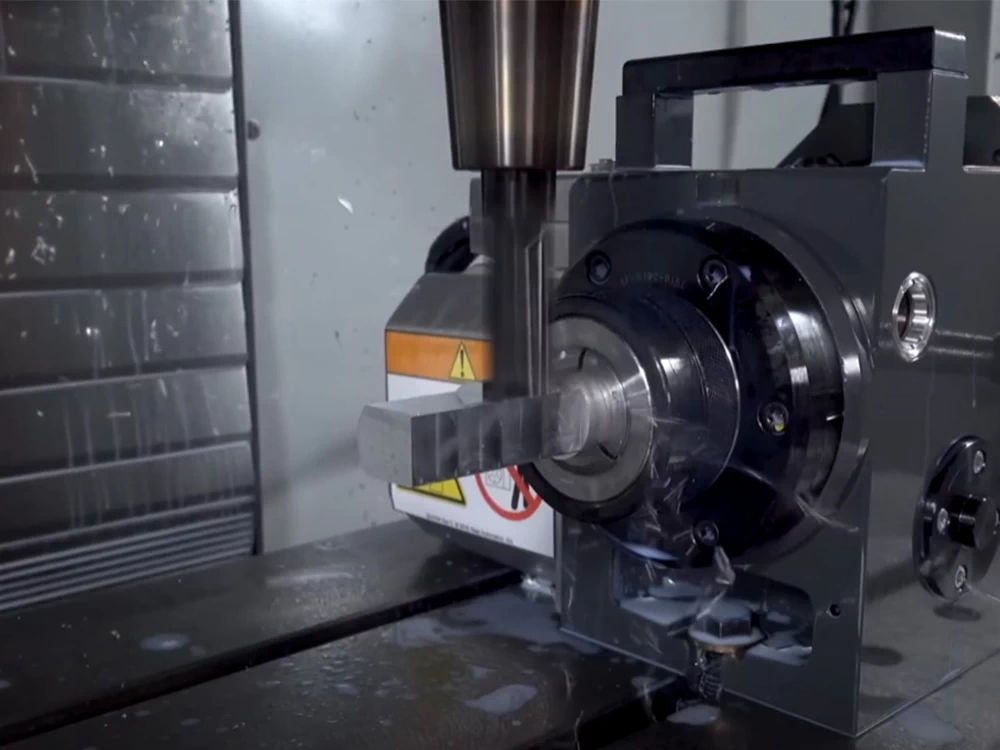

4 Axis Milling

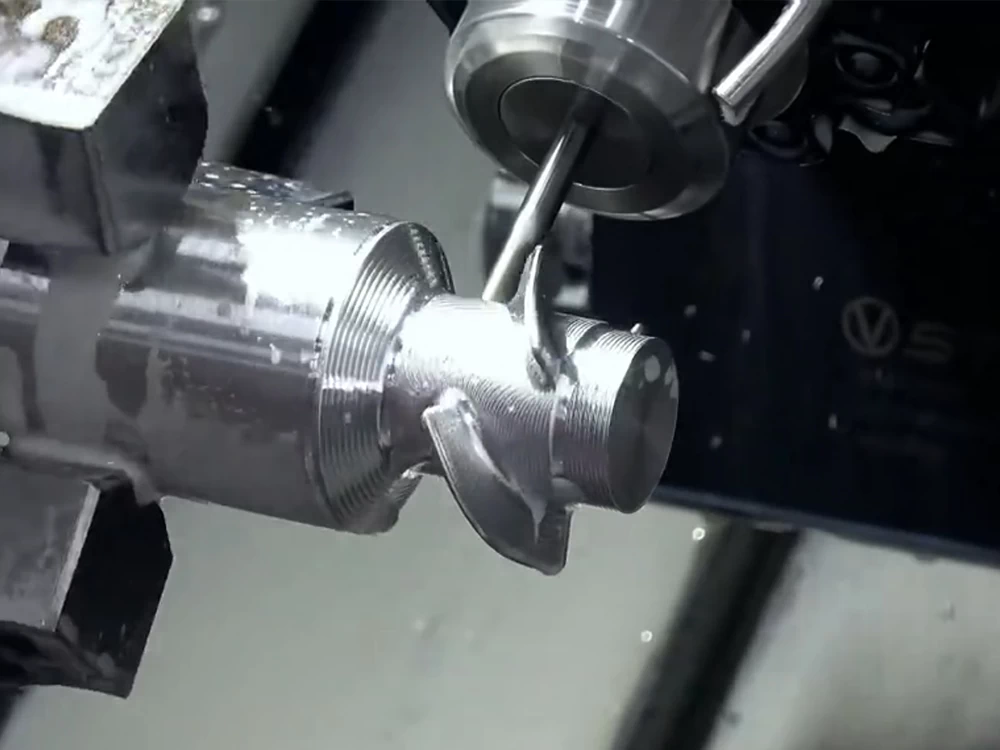

5 Axis Milling

Turn-Milling

We offer single-side 3-axis machining, single-side 5-axis machining, with a minimum feature size and nominal thickness of 0.039 in (1 mm).

| Maximum Dimensions | Material | US | Metric |

| 3-axis** | ABS | 33.46 in. ×19.69 in. | 850mm × 500mm |

| POM | |||

| Nylon | |||

| pc | |||

| 3-axis** | Stainless steel | 33.46 in. ×19.69 in. | 850mm × 500mm |

| Titanium | |||

| Mild steel | |||

| Tool steel | |||

| 3-axis** | Aluminum | 33.46 in. ×19.69 in. | 850mm × 500mm |

| Cast iron | |||

| Copper | |||

| 5-axis | ABS | 10 in. x 7 in. | 254mm x 178mm |

| POM | |||

| 5-axis | Aluminum | 10 in. x 7 in. | 254mm x 178mm |

| Copper |

| Maximum Dimensions | US | Metric |

Size | 0.25 in. x 0.25 in. | 6.35mm x 6.35mm |

Nominal Thickness | 0.039 in. | 1mm |

*Hard metals: Ti 6Al-4V, stainless steels (303, 304, 316, 17-4PH), alloy steel (4140)

**Two-sided machining only.

Aluminum | Brass | Copper | Stainless Steel | Alloy Steel | Steel Mild | Titanium | Low Carbon

ABS丨Acetal 丨CPVC丨 HDPE | LDPE丨 Nylon丨 PEEK丨 PEI | PET丨PMMA丨Polycarbonate | Polypropylene 丨 POM(Delrin) | PPSU 丨HIPS丨 PSU丨 PTFE丨 PVC

Surface finish we can provide

A precision mechanical finishing process that smooths and refines metal surfaces to a high-gloss or satin sheen, polishing reduces surface roughness, removes abrasions, and enhances part appearance and wear resistance without sacrificing dimensional accuracy.

A high-velocity abrasive blasting technique that propels fine media against the workpiece to uniformly remove scale, rust, and surface contaminants, sandblasting creates a clean, textured profile ideal for improved coating adhesion and consistent matte finishes.

A liquid coating applied via spray, dip, or brush that cures to form a durable protective film, painted finishes offer customizable color options, outstanding chemical and weather resistance, and a uniform appearance across complex geometries.

An electrochemical conversion process that builds a controlled oxide layer on aluminum alloys, anodizing delivers enhanced corrosion resistance, increased surface hardness, and a decorative, UV-stable finish available in a spectrum of colors without adding significant thickness.

A controlled chemical treatment that removes free iron and enhances the natural oxide layer on stainless steels, passivation delivers superior corrosion resistance and a clean, non-contaminating finish without altering part dimensions.

A salt-bath conversion process that produces a uniform, low-reflective black finish on ferrous metals, black oxide coating improves corrosion protection, minimizes light glare, and maintains tight machining tolerances.

We have an entire manufacturing process for all product mass production, professional engineers team and the best CNC machining, thus we can control the quality and the lead time for your products for production

1. Process Engineering

2. Raw Material Ordering

3. Programming Commissioning

4. 1st Sample Approved

8. Packaging After 2nd Inspection

7. Surface Finished

6. Initial Dample Inspection

5. Mass Production

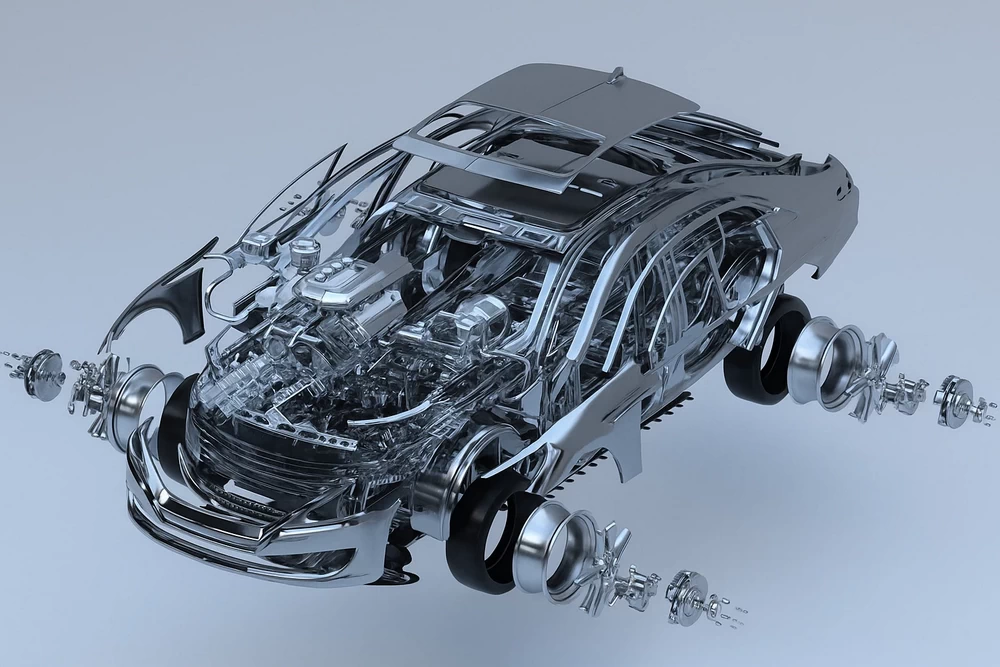

All industrial you can get CNC parts from our service, we are the best choice for you!

FAQ’s about our CNC milling services

Grinding uses an abrasive wheel to achieve a very fine surface finish and tight tolerances, often as a final step. Milling uses a rotating multi-toothed cutter on a stationary workpiece to create complex shapes, slots, and flat surfaces. Turning involves a stationary cutting tool shaping a rotating workpiece, typically to create cylindrical parts. Turning-milling, or mill-turn, is a hybrid process on a single machine that combines both turning and milling capabilities for more complex parts.

We are able to achieve a consistent tolerance range of ±0.005mm.

We offer common surface finishes for CNC-milled parts, including coatings like powder coating and anodizing for enhanced durability and corrosion resistance. Mechanical options like bead blasting , polishing and brushing create a smooth or reflective surface. Chemical treatment like passivation for stainless steel to improve rust resistance. The choice depends on the your required appearance, environmental exposure, and function of the part.

Learn more finishing options here.

Here are the industries for the parts you can see in different realm.

You can send us any questions to get any information you would like to know, and we will respond to you in extremely short time.