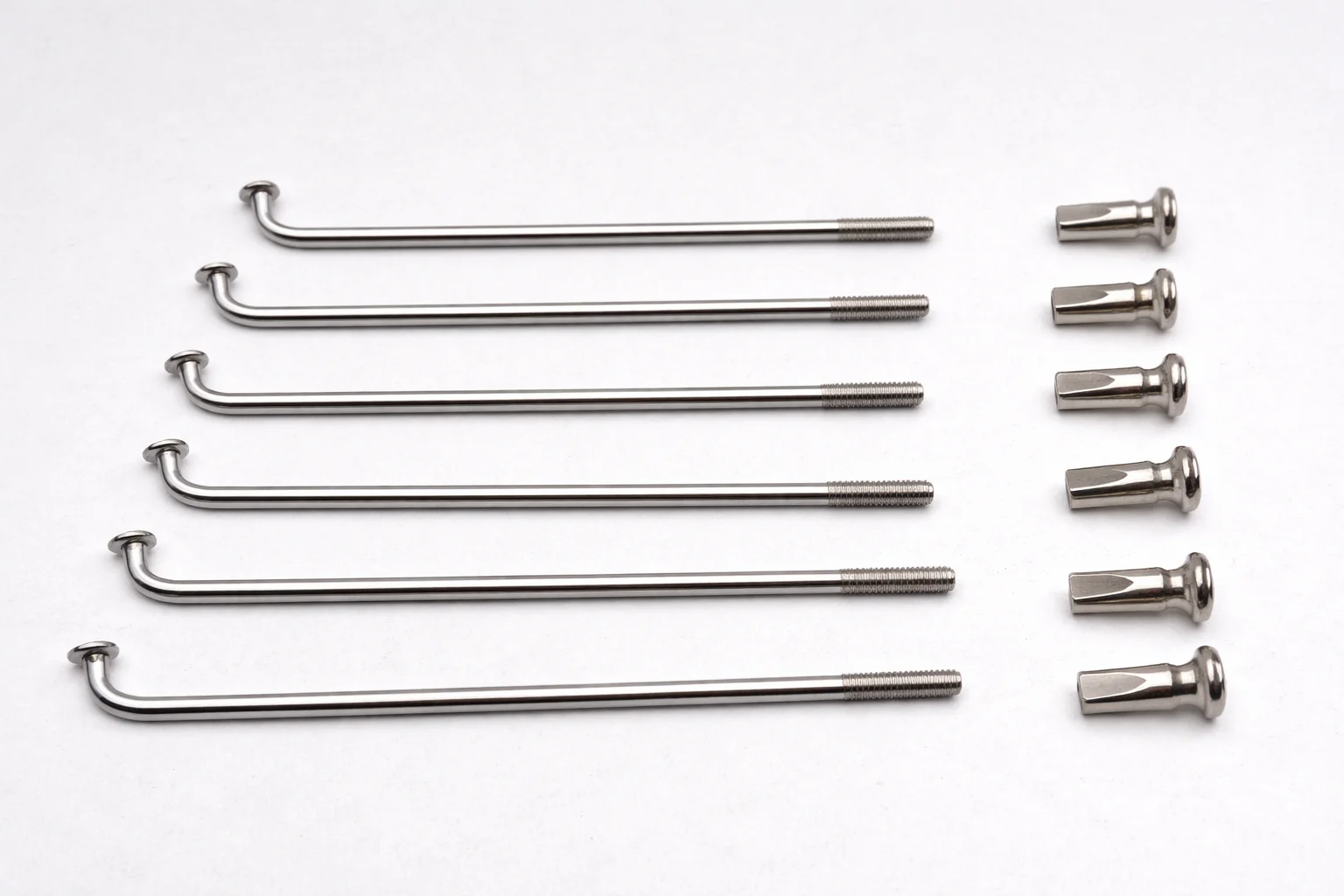

Precision-Engineered Brake Calipers, Levers & Rotors | Tolerances ±0.01mm | ISO 9001 Certified

We specialize in manufacturing high-performance bicycle brake components using advanced CNC machining technology. From prototypes to mass production, we deliver precision parts that meet the demanding requirements of professional cycling and everyday riders.

Superior Precision

Achieve tolerances as tight as ±0.005mm for consistent braking performance and perfect fitment.

Enhanced Strength

Machined from solid billets, eliminating weak points found in cast or forged alternatives.

Lightweight Design

Strategic material removal creates optimal strength-to-weight ratios for competitive cycling.

Design Flexibility

Complex geometries and custom designs easily achievable for OEM and aftermarket applications.

Durability

Superior surface finish and material integrity for extended service life in all conditions.

Rapid Prototyping

From CAD to physical part in as few as 3-5 days for quick design validation.

Get a free quote within 24 hours. Our team of cycling component specialists is ready to help.

| Material | Properties | Best For |

|---|---|---|

| 6061-T6 Aluminum | Lightweight, corrosion-resistant, excellent machinability | Brake levers, calipers, adapters |

| 7075-T6 Aluminum | High strength, superior fatigue resistance | High-performance calipers, racing components |

| Titanium (Ti-6Al-4V) | Ultimate strength-to-weight, corrosion-proof | Premium/professional-grade brakes |

| Stainless Steel 304/316 | High durability, weather resistant | Brake hardware, pistons, pins |

| Carbon Steel | High hardness, wear resistant | Brake rotors, mounting bolts |

Equipment:

• 5-Axis CNC Machining Centers

• CNC Turning with Live Tooling

• Swiss-Type CNC Lathes

• Wire EDM for Complex Geometries

Specifications:

• Tolerance: Up to ±0.005mm

• Surface Finish: Ra 0.4μm achievable

• Part Size: 1mm – 500mm

• Production Volume: 1 to 100,000+ units

Secondary Operations:

• Anodizing (Type II & III, multiple colors)

• Bead Blasting & Brushing

• Laser Engraving & Logo Marking

• Heat Treatment

• Assembly Services

What file formats do you accept for CNC machining quotes?

A: We accept STEP, IGES, STP, X_T, DWG, DXF, and PDF with dimensions. STEP format is preferred for accurate quoting.

What is the minimum order quantity for bicycle brake parts?

A: No MOQ required. We handle everything from single prototypes to production runs of 100,000+ units.

How long does it take to manufacture CNC machined brake components?

A: Prototypes: 5-7 business days. Production orders: 2-4 weeks depending on quantity and complexity.

Can you match existing brake components or create custom designs?

A: Yes, we offer reverse engineering services and can work from samples, sketches, or your CAD designs.

What surface finishes are available for aluminum brake parts?

A: Options include anodizing (Type II/III, various colors), bead blasting, brushing, polishing, and powder coating.

Here are the industries for the parts you can see in different realm.

You can send us any questions to get any information you would like to know, and we will respond to you in extremely short time.