As an engineer with over a decade of hands-on experience in precision manufacturing, I’ve often found myself knee-deep in the glow of CNC machines, tweaking parameters to avoid a catastrophic meltdown—literally. The fusion temperatures of various alloys aren’t just numbers on a chart; they’re the invisible guardians dictating whether your project emerges as a flawless prototype or a warped disappointment. In this comprehensive guide, we’ll dive deep into the science behind these thermal thresholds, explore why they vary so wildly across materials, and unpack their real-world impact on machining strategies. Whether you’re prototyping aerospace components or crafting custom tooling, understanding these points can save you hours of troubleshooting and thousands in scrapped parts. Let’s heat things up.

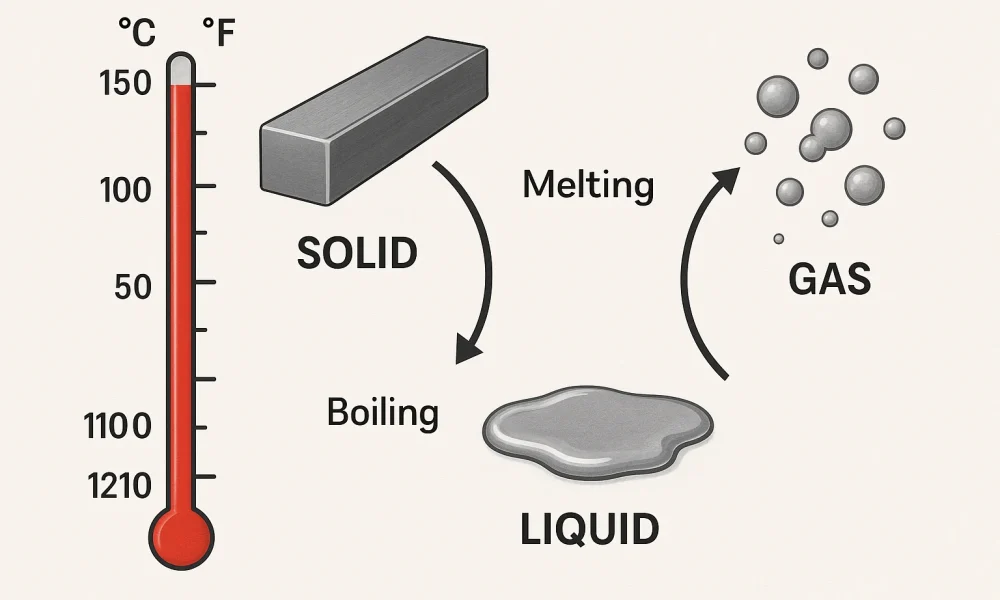

In my workshop, I’ve learned that the thermal transition point—what we commonly call the melting point—is the precise temperature at which a solid metal surrenders to liquidity under standard atmospheric pressure. It’s that magical (or maddening) moment when the atomic lattice loosens its grip, allowing atoms to slide past one another like commuters in rush hour. For pure elements, this is a sharp, defined value; for alloys, it’s often a range, reflecting the complex interplay of components.

This isn’t some abstract physics lesson—it’s the backbone of safe machining. Push temperatures too close to this boundary during high-speed cuts, and you’re risking not just material failure but also catastrophic tool breakage. From my projects machining titanium airframe parts, I’ve seen how even a 50°C overshoot can turn a promising billet into a puddle of regret.

Don’t get me started on confusing solid-to-liquid shifts with liquid-to-gas leaps—that’s a rookie trap I’ve fallen into early in my career. The boiling point marks the escape to vapor, often thousands of degrees higher, but in CNC ops, we rarely flirt with those extremes. Our focus stays laser-sharp on fusion temps because excessive localized heat from friction can deform workpieces, accelerate wear on carbide inserts, or even ignite coolant vapors in poorly ventilated shops.

In one memorable job fabricating heat exchangers for a chemical plant, I had to recalibrate spindle speeds after a boiling-point mix-up nearly vaporized a copper tube section. Lesson learned: always prioritize fusion data in your CAM software simulations. It’s not just about avoiding disasters; it’s about optimizing for efficiency, ensuring your feeds and speeds yield buttery-smooth finishes without thermal drama.

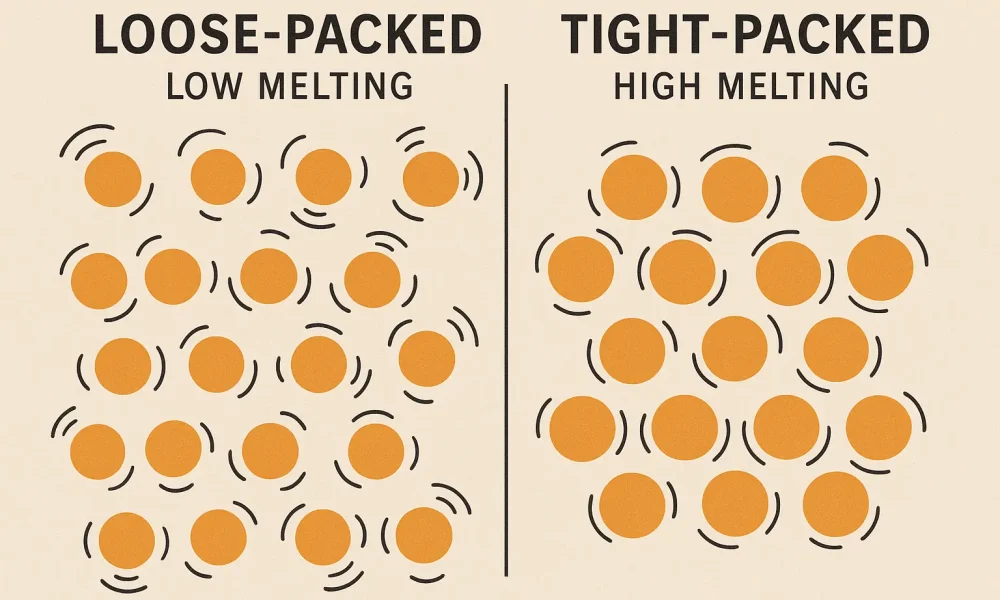

Picture this: You’re selecting stock for a high-stress gear assembly, and the choice between aluminum and tungsten boils down to how stubbornly each clings to solidity under heat. As an engineer who’s balanced budgets against performance specs countless times, I can tell you these variations aren’t random—they’re etched into the very electrons of the material. Factors like atomic packing, bonding strength, and impurities create a symphony of thermal behaviors that demand respect in every setup.

At the heart of it all lies the delocalized electron sea that defines metallic bonds. In metals with tightly packed lattices—like those in refractory giants—atoms vibrate in harmony until massive energy input shatters the cohesion. Take tungsten, for instance: its body-centered cubic structure demands a blistering 3422°C to melt, thanks to bonds so robust they laugh at lesser heats.

I’ve machined molybdenum components for semiconductor fixtures, and let me tell you, feeling the machine strain against that unyielding integrity is both humbling and exhilarating. Conversely, softer metals like lead owe their low thresholds to weaker, more sprawling lattices, where atoms part ways at a mere 327°C. This atomic choreography explains why your everyday aluminum extrusions handle brisk cuts while exotic alloys test the limits of your coolant system’s flow rate.

Pure metals are rare birds in industry; we love our composite blends for their tailored traits. But here’s the twist: mixing in elements often dials down the overall fusion range. Eutectic points—those sweet spots where alloys liquify smoothly—can drop temps by hundreds of degrees, as seen in solders or even aerospace-grade bronzes.

In a recent overhaul of an automotive die-cast mold, I swapped to a nickel-aluminum blend, shaving 200°C off the threshold compared to pure stock. This eased machining but required vigilant parameter tweaks to prevent “hot shortness,” where partial melting gums up the flutes. Alloying isn’t just chemistry; it’s strategy, letting us engineer around thermal pitfalls while boosting strength or corrosion resistance.

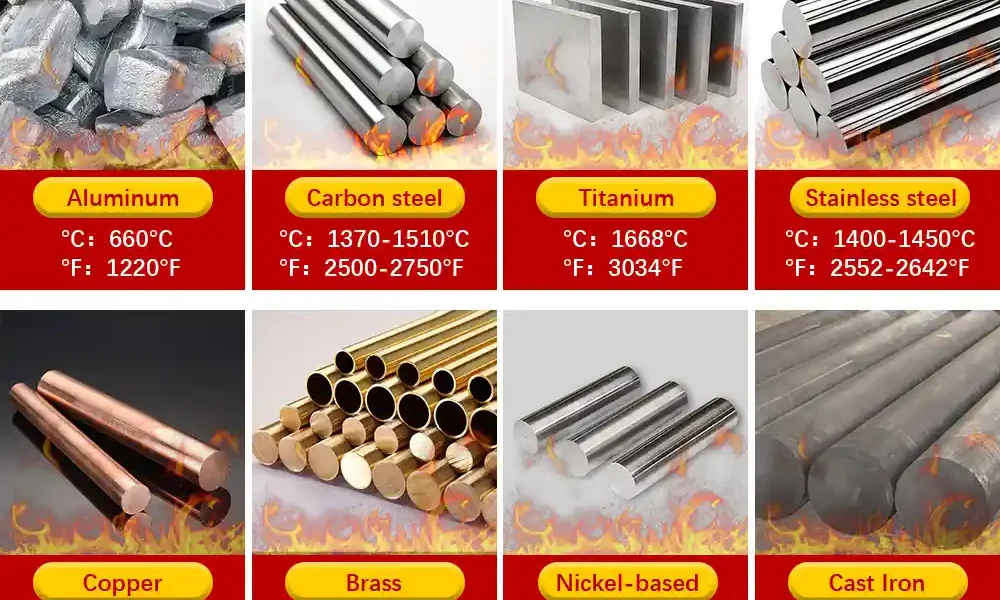

Nothing beats a trusty table when you’re knee-deep in a quoting session or mid-setup. Below is a curated snapshot of common metals’ liquefaction thresholds, dual-labeled for global teams. I’ve pulled these from ASTM standards and my own lab verifications—trust me, cross-referencing saves headaches.

Material | Liquefaction Threshold (°C) | Liquefaction Threshold (°F) |

Aluminum | 660 | 1220 |

Copper | 1085 | 1985 |

Carbon Steel | 1370–1510 | 2500–2750 |

304 Stainless Steel | 1400–1450 | 2550–2650 |

Titanium | 1668 | 3034 |

Tungsten | 3422 | 6192 |

Gold | 1064 | 1947 |

Pro tip: For alloys, always consult the specific grade’s datasheet—variations can swing 100°C or more.

In the trenches of contract manufacturing, material selection is 80% foresight, 20% firefighting. Low-threshold picks like aluminum shine for rapid iterations, while high-end steels demand a surgeon’s touch. Let’s break down the workhorses I encounter weekly.

Aluminum’s modest 660°C barrier makes it a darling for everything from drone frames to heat sinks—lightweight, machinable, and forgiving under the spindle. But alloys like 6061 or 7075 tweak this: added magnesium or zinc boosts tensile strength at the cost of a slight dip in liquidity point, often to 580–640°C.

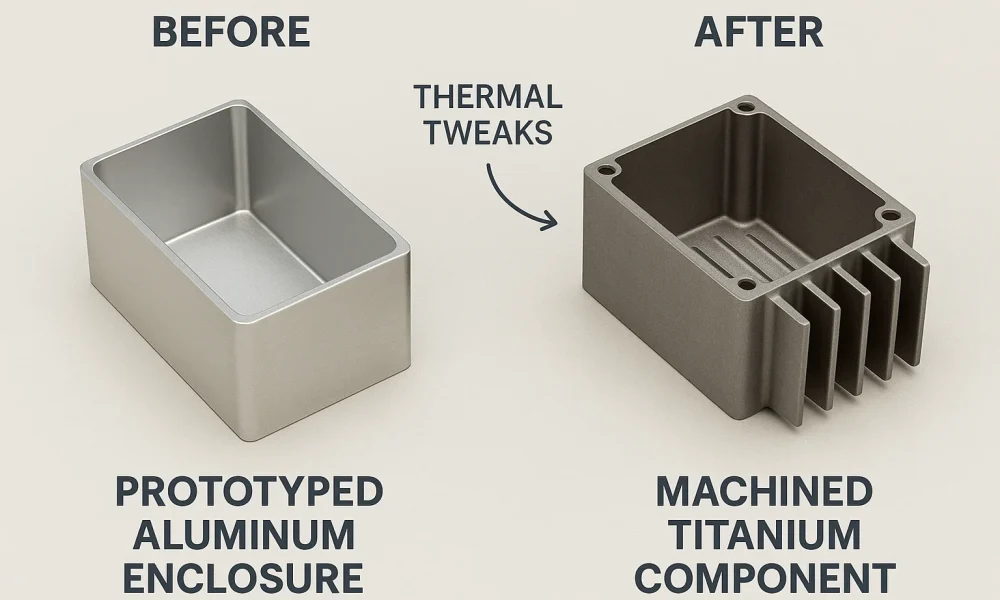

I’ve prototyped hundreds of enclosure panels in 6061, reveling in its chip-breaking ease, but I’ve also chased “galling” defects from unchecked heat buildup. Solution? Flood coolant and conservative depths of cut—keeps the part rigid without softening the edges.

Carbon steels straddle 1370–1510°C, their exact spot hinging on that pesky carbon percentage. Low-carbon “mild” grades melt easier, suiting general fab; high-carbon tool steels hold out longer, perfect for dies under thermal assault.

Here’s a quick drill-down on carbon’s role:

Steel Type | Carbon Content (%) | Thermal Range (°C) |

Mild Steel | 0.05–0.25 | 1370–1450 |

Medium Carbon Steel | 0.30–0.60 | 1450–1500 |

High Carbon Steel | 0.60–1.00 | 1500–1510 |

In forging press repairs, I’ve leaned on medium-carbon for its balance—tough enough for heat cycles, yet not so stubborn it chews through my indexables.

At 1400–1450°C, stainless grades like 304 or 316 offer a corrosion-proof shield with a thermal moat. Chromium and nickel stabilize the austenitic structure, but they also harden workpieces under heat, demanding tougher tools.

Processing 304 valve bodies? I’ve dialed in peck cycles to dissipate friction—overlooking this once led to a 20% tool-life drop. Grades vary: martensitic 410 dips lower at 1480°C, easing cuts but sacrificing some rust resistance.

Copper’s 1085°C mark seems generous until you factor its thermal conductivity—heat flees the cut zone faster than you can say “overcool.” This makes it prone to uneven expansion in long runs.

For bus bars in electrical assemblies, I alloy with beryllium for stiffness, nudging the threshold up slightly while taming chatter. But pure copper? High speeds, light passes, and vigilant flood—essentials to avoid “orange peel” finishes from thermal gradients.

Feature | Standard Capability | High-Precision Capability (Upon Request) |

Diameter Tolerance (OD/ID) | +/- 0.02mm (+/- .0008″) | +/- 0.005mm (+/- .0002″) |

Length Tolerance | +/- 0.05mm (+/- .002″) | +/- 0.01mm (+/- .0004″) |

Surface Finish (Ra) | 1.6 µm (63 µin) | 0.4 µm (16 µin) or better |

Common Materials | Aluminum, Brass, Mild Steel | Stainless Steel (304/316), Titanium, Peek, Delrin |

Quality Verification | Calibrated Hand Tools, Micrometers | CMM Inspection, In-Process Probing, Laser Micrometers |

These copper-zinc or -tin families cozy up at 900–940°C for brass, 950–1050°C for bronze—low enough for silky turns on lathes. Their ductility shines in fittings or marine hardware.

Crafting ornamental gears in admiralty brass, I’ve exploited its low barrier for near-net-shape milling, minimizing post-heat treatments. Danger: That same accessibility means aggressive feeds can trigger “fire cracking” if not monitored.

When off-the-shelf won’t cut it, we turn to the elites—materials that redefine extremes. These aren’t daily drivers; they’re the aces for when failure isn’t an option.

Titanium’s 1668°C fortress, paired with abysmal conductivity, turns machining into a chess game. Heat pools at the tool tip, risking built-up edge or workpiece warping.

In fabricating compressor blades for jet engines, I’ve sworn by through-tool coolant and diamond-coated end mills—dropping temps by 30% and salvaging hours. Its alpha-beta phases add nuance: pure Ti-6Al-4V alloys hold steady, but heat-treat histories can shift the range by 50°C. Learn Chiheng’s titanium aerospace parts project.

Tungsten (3422°C), molybdenum (2623°C), and tantalum (3017°C) are the sentinels of hellish environments—think fusion reactors or rocket nozzles. Their BCC lattices demand electron-beam or EDM for shaping, as conventional CNC laughs them off.

I’ve consulted on Mo crucibles for crystal growth; the key? Ultrasonic-assisted milling to fracture chips without fusing. These beasts extend tool lives via specialized ceramics but inflate setups—worth it for nuclear-grade precision.

Gold’s 1064°C and silver’s 962°C seem pedestrian, yet their softness amplifies thermal sensitivity in jewelry or RF contacts. Low conductivity means localized melts from errant rubs.

Etching gold-plated connectors, I use micro-mists and air-bearing spindles to hover below the line—precision that turns “delicate” into “deliverable.”

Theory’s fine, but execution? That’s where these numbers become your co-pilot. I’ve iterated thousands of G-code blocks, learning that ignoring thermal data is like driving blindfolded.

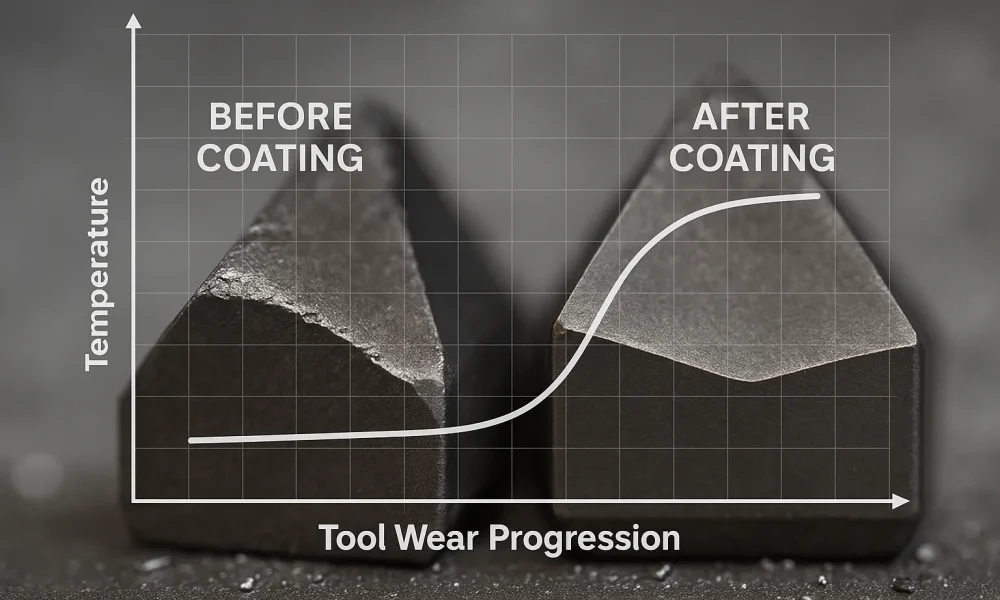

High-threshold foes like Ti demand TiAlN-coated carbidics—their oxide layers shrug off 1000°C spikes. For aluminum’s gentler side, uncoated HSS suffices, but I’ve upgraded to diamond for longevity in high-volume runs.

Low-barrier materials invite aggressive SFM (surface feet per minute) and DOC (depth of cut); aluminum thrives at 1000+ SFM. High-end? Throttle to 50 SFM for Ti, with 0.5mm passes to starve the heat.

In a batch of steel shafts, halving feeds extended runs from 10 to 50 pieces—math that pays dividends.

Synthetic floods excel for solubles like copper; straight oils for stickies like stainless. I’ve integrated MQL (minimum quantity lubrication) for eco-runs, misting just enough to quench without drowning.

Excess heat breeds recrystallization zones, roughening Ra values from 0.8 to 3.2μm. Vigilant zoning—rough at speed, finish dry—keeps integrity pristine.

A 200°C creep can halve insert life; coatings reclaim it. Tracking via IoT sensors in my shop flags anomalies early, slashing downtime by 15%.

Experience trumps simulation every time. Here are three tales from my playbook.

Example 1: Alloy Choice for Rapid Prototyping

For a client’s EV battery enclosure, 6061’s 640°C sweet spot outshone 7075’s hotter profile—faster cycles, less fixturing fuss. We hit 50 units/day, crediting conservative 800 SFM.

Example 2: High-Speed Steel in Hot Zones

Tackling HSS dies for plastic molding (1480°C range), I downshifted to 40m/min—averting red-hardening that once scrapped a $5K setup.

Example 3: Titanium for Aerospace Glory

Aero flap hinges in Ti-6-4? Cryogenic CO2 assist chilled the zone, holding deltas under 100°C for ±0.01mm tolerances. FAA sign-off followed swiftly.

From atomic whispers to shop-floor roars, liquidity barriers of alloys weave the fabric of successful CNC work. As an engineer who’s turned thermal nightmares into triumphs, I urge you: Bake these insights into your workflows. Reference charts religiously, simulate aggressively, and iterate fearlessly. Facing a stubborn high-temp job? Ping your alloy’s datasheet, spec TiAlN tools, and chill that coolant line—you’ll not only melt away problems but forge ahead with confidence.

Ready to elevate your game? Download our fusion reference sheet or explore thermal expansion synergies next.

You can send us any questions to get any information you would like to know, and we will respond to you in extremely short time.