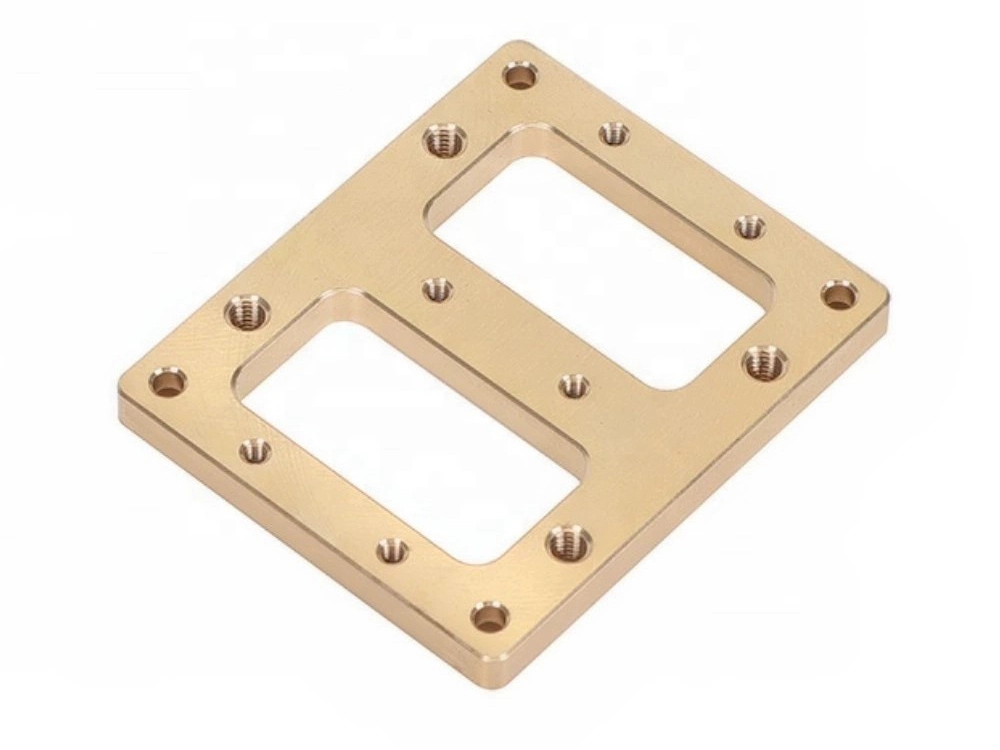

| Material | Brass |

| Processing | CNC Milling |

| Surface Treatment | Brushing |

| Application | Structural components, end-of-arm tooling(EOAT), mounting brackets and bases, joint connectors, end-effectors or grippers |

By selecting the right brass alloy, robotics manufacturers can ensure parts are lightweight yet strong, work efficiently in electronic systems, and perform consistently in demanding environments.

At Chiheng, we use advanced CNC milling technology to produce precision brass parts for robotic applications with consistent accuracy. Our multi-axis CNC machines can handle complex geometries and tight tolerances, which is essential for components like robotic brass gears, high-precision connectors, and actuator parts.

We work to tolerances as fine as ±0.01mm, ensuring every piece fits and functions exactly as designed. For surface finishing, we offer a range of options – from smooth machining finishes to polishing and coating – to meet both functional and visual requirements, including corrosion-resistant brass robotics components.

Whether you need a small batch of custom brass robotics parts for prototyping or large-scale production runs for ongoing supply, our workshop is set up for flexible output. This means we can support UK robotics manufacturers, OEMs, and startups with dependable lead times and consistent quality across every order.

Brass milling parts play a big role in many areas of the robotics industry thanks to their strength, precision, and conductivity. In the UK, we often see demand for these parts in both industrial automation and advanced research projects. Common CNC machined brass components for robotics include:

Robotic manufacturers and automation companies value brass for its excellent electrical conductivity and corrosion resistance, making it reliable for long-term operation in various environments. For example, in pick-and-place machines, brass milled parts keep movements consistent and accurate. In mobile robots, custom brass robotics parts such as pivot joints and drive train elements are chosen for their durability without adding excess weight.

From laboratory robotics to heavy-duty automation, brass CNC milling services deliver parts that not only fit perfectly but also keep performance standards high. Whether for one-off prototypes or repeat production runs, these parts keep UK robotics projects running smoothly and efficiently.

You can send us any questions to get any information you would like to know, and we will respond to you in extremely short time.