Get custom CNC acrylic projects tailored to your drawings or samples. Chiheng provides rapid prototyping, high-volume production capabilities, and expert technical consultation.

Chiheng provides custom CNC machined acrylic parts with high precision, excellent optical clarity, and consistent quality. From rapid prototypes to low- and mid-volume production, we deliver reliable CNC acrylic machining services tailored to your drawings, specifications, and application requirements.

With advanced CNC milling and turning equipment, experienced machinists, and strict quality control, we help global customers manufacture complex PMMA (acrylic) components efficiently and cost-effectively.

Yes, acrylic can be machined efficiently and accurately using CNC equipment. Machining acrylic with CNC milling and turning allows the production of complex geometries that cannot be achieved through simple cutting processes.

Our cnc acrylic service supports:

Precision drilling, slotting, and contouring

Threaded holes and assembly-ready features

Consistent quality for prototypes and production runs

By using optimized tooling and controlled machining parameters, we minimize internal stress and achieve reliable results for acrylic machined parts.

Acrylic (PMMA) is widely used across industrial and commercial applications due to its transparency, lightweight nature, and machinability. CNC machining is one of the most effective methods to produce precision acrylic parts with tight tolerances and complex geometries.

Key advantages include:

High dimensional accuracy and repeatability

Smooth surface finishes suitable for optical and aesthetic applications

Ability to machine complex 2D and 3D features

Consistent quality from prototype to production

CNC machining ensures your custom acrylic parts meet functional, visual, and assembly requirements.

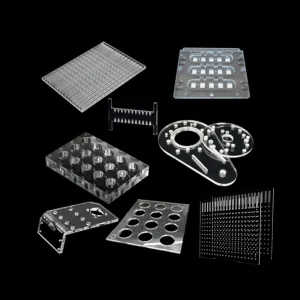

CNC Milling acrylic allows precise control of depth, geometry, and surface finish. Our CNC milling process is ideal for producing complex acrylic machined parts such as housings, panels, frames, and structural components that require tight tolerances and clean edges.

For cylindrical or rotational acrylic components, CNC turning processiong delivers excellent concentricity and smooth surface finishes. Typical applications include acrylic bushings, spacers, lenses, and round housings.

Acrylic cutting processes such as laser cutting or basic sheet cutting are commonly used for simple, flat acrylic components with 2D profiles. These methods are cost-effective and suitable for parts that do not require tight tolerances, complex features, or secondary machining.

We maintain strict process control to ensure stable and repeatable quality for CNC acrylic service projects. Typical machining capabilities are summarized below:

Capability Item | Typical Range | Notes |

Dimensional Tolerance | ±0.05 mm to ±0.10 mm | Depends on geometry and part size |

Minimum Wall Thickness | ≥ 1.0 mm | Design review recommended for thin walls |

Hole Diameter Accuracy | ±0.05 mm | Suitable for assembly-ready features |

Surface Finish (As Machined) | Ra 1.6–3.2 μm | Polishing available for optical clarity |

Batch Size | Prototype to mid-volume | Consistent quality across runs |

Our custom CNC acrylic solutions support a wide range of industries that rely on durable and visually clean plastic components. We manufacture custom acrylic parts that meet functional, aesthetic, and assembly requirements across multiple applications.

LED lighting components and light guide panels

Electronic device housings and transparent covers

Medical equipment components and laboratory parts

Display fixtures, signage, and retail systems

Prototypes, models, and functional testing parts

Typical tolerances range from ±0.005 mm to ±0.1 mm, depending on part geometry, size, and finishing requirements.

Cast acrylic offers better optical clarity and machining performance, while extruded acrylic is more economical and suitable for less demanding applications.

Yes. With proper material selection and polishing processes, CNC machined acrylic parts can achieve high optical transparency.

Yes. We specialize in both rapid prototyping and low- to mid-volume production of custom acrylic parts.

Our experienced machinists and optimized tooling allow us to handle complex geometries and thin-wall designs while minimizing stress and cracking.

You can send us any questions to get any information you would like to know, and we will respond to you in extremely short time.