Description

Valve components encompass numerous critical parts such as valve bodies, valve covers, valve cores, valve stems, and seals. The machining precision and quality of each individual part profoundly influence the valve's performance. Firstly, valve bodies and covers serve as the primary enclosures, and their material selection, internal structure, and processing directly affect sealing and durability. High-quality valve bodies and covers effectively prevent leaks, ensure fluid control accuracy, and lower system maintenance costs.

Secondly, valve cores and stems constitute the core elements of valves, with their machining precision and surface smoothness being vital for flexibility and sealing. Precise machining ensures a tight fit between valve cores and seats, facilitating accurate fluid control. The surface smoothness of valve stems is directly linked to the lifespan of seals and the ease of valve operation.

As a critical component of valves, seal materials' selection and processing quality determine sealing performance. Appropriate seal materials can maintain stable sealing effectiveness under harsh conditions such as high temperatures and pressures, preventing leaks and ensuring system safety.

In industrial production, the machining quality and precision of valve components are indispensable, influencing production line stability, cost control, and equipment lifespan. Utilizing advanced machining techniques and high-quality materials guarantees excellent valve component performance. Simultaneously, rigorous quality control and testing methodologies are pivotal in ensuring the quality of valve components. Only through strict attention to every detail can valves operate stably under diverse challenging conditions, ensuring smooth production processes, lowering maintenance costs, and enhancing equipment utilization.

Cross-Field Applications: Valve components are crucial system elements that not only support, control, and maintain fluid systems but also ensure their stability and safety. In various industrial fields like petroleum, chemicals, power generation, water treatment, pharmaceuticals, and manufacturing, valve components play an indispensable and vital role.

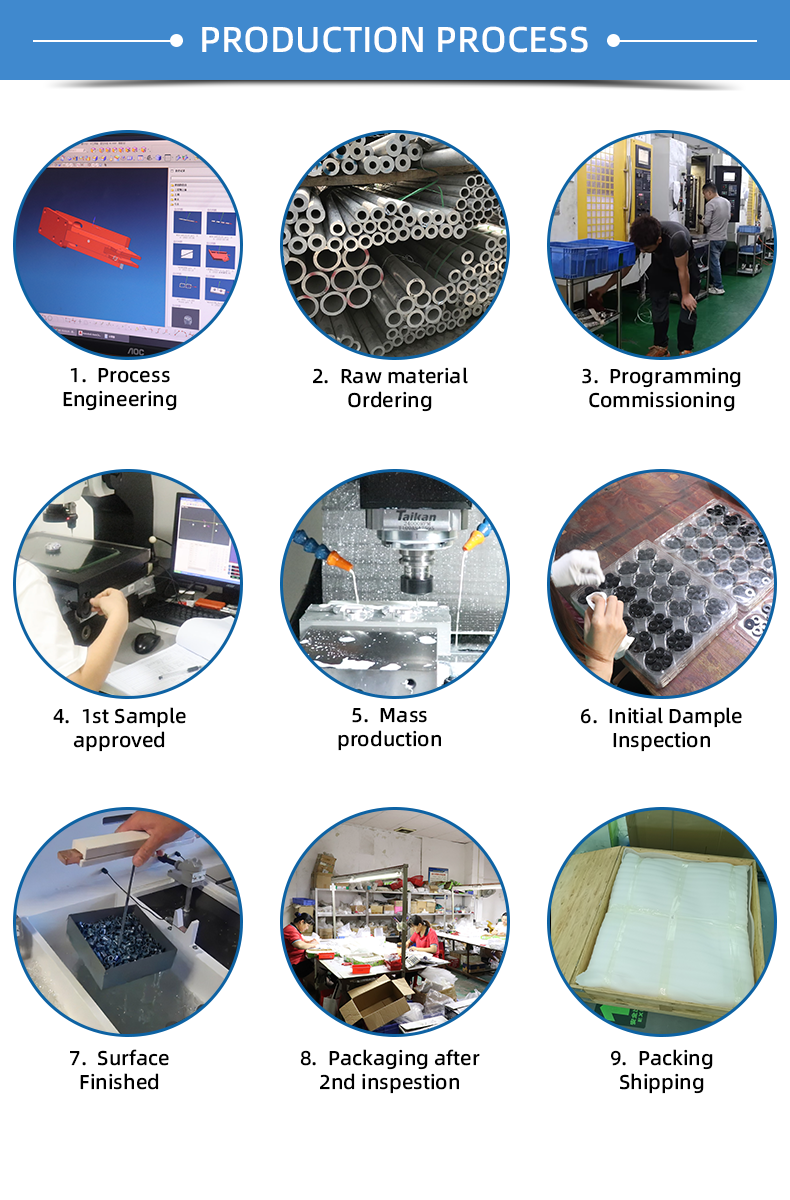

Exquisite Craftsmanship: We employ advanced techniques in manufacturing valve components, aiming to endow products with outstanding quality and longevity. The entire production process adheres rigorously to quality control standards, from meticulous material selection and advanced processing techniques to surface treatment and comprehensive product testing. Our products embody superior quality. We utilize high-quality materials like stainless steel, cast iron, and titanium to ensure exceptional performance in various environments.

Outstanding Performance: Our valve components possess the following remarkable features:

Corrosion Resistance: Manufactured using corrosion-resistant materials, these components can be used in corrosive environments, reducing maintenance frequency and costs.

Superior Sealing: Precision design and calculations ensure valves have exceptional sealing performance, effectively preventing fluid leaks and enhancing system safety.

Strength and Pressure Resistance: Our components are professionally designed, boasting excellent strength and stability, capable of withstanding high pressures, temperatures, vibrations, and other extreme conditions.

Precise Production: The manufacturing process ensures precision and consistency for each component, guaranteeing seamless integration into various valve systems.

Our goal is to provide customers with reliable and efficient valve components that cater to various industrial application needs. Whether in fluid control, flow regulation, or fluid isolation, our products are up to the task, offering reliable support for customer production operations.

Dongguan Chiheng Hardwrare Co.,Ltd is a professional OEM metal fabrication factory which is located in Chang'an, Dongguan, China,and specialize in this field since 2009.

Our main business are CNC machining, plastic injection molding, die casting ,extrusion,Investment Casting and stamping parts.

We now have sophisticated CNC machining centers, engraving and drilling machine, lathe and milling machine, line cutting and other equipment.

With these machines and experienced employees, we are able to make repeated positioning accuracy within tolerance 0.005mm, providing strong guarantee for precision parts.

With great Service and nice quality,our products have been exported to USA, South America, Europe, Australia, Middle east and Southeast Asia, etc.Our goal is to make every customer happy.