Description

In the world of CNC machining, turning aluminum parts stands as a critical process that demands both precision and expertise. At Chiheng Hardware Co., Ltd., we specialize in delivering high-quality aluminum components that meet the stringent requirements of various industries, from aerospace to automotive, electronics to medical devices.

Unmatched Precision and Efficiency

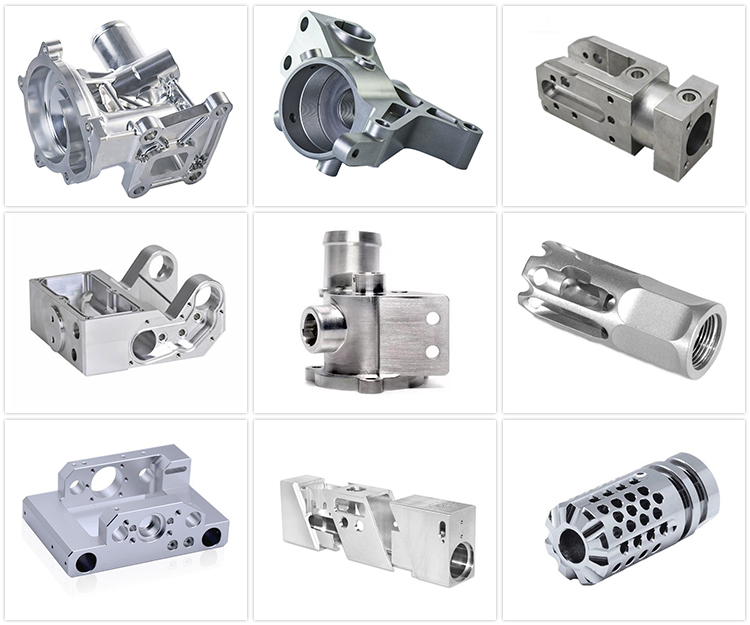

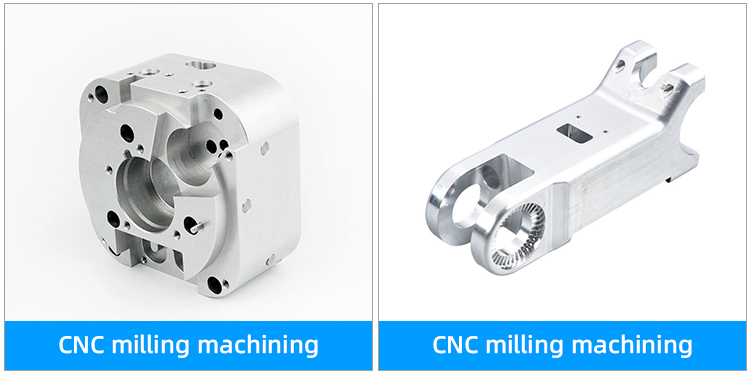

Aluminum is a favored material in manufacturing due to its lightweight, excellent corrosion resistance, and high strength-to-weight ratio. However, machining aluminum, particularly turning, requires specialized knowledge and state-of-the-art equipment to achieve the desired results. At Chiheng Hardware Co., Ltd., our advanced CNC lathes are equipped with the latest technology, allowing us to produce aluminum parts with unparalleled accuracy, ensuring that every piece meets the exact specifications of our clients.

Tailored Solutions for Diverse Industries

Our turning capabilities extend to a wide range of aluminum grades, including 6061, 7075, and 2024, among others. Each of these alloys offers unique properties suitable for specific applications, and our expert engineers will guide you in selecting the right material for your project. Whether you need prototypes, small batches, or large-scale production, we are equipped to handle orders of any size with consistent quality.

Surface Finishes and Post-Processing

Beyond precision turning, we understand the importance of a flawless finish. Our comprehensive range of post-processing services, including anodizing, polishing, and bead blasting, ensures that the final product not only meets functional requirements but also achieves the desired aesthetic appeal. The smooth, refined surfaces of our aluminum parts are ideal for components that require both strength and visual appeal.

Commitment to Quality

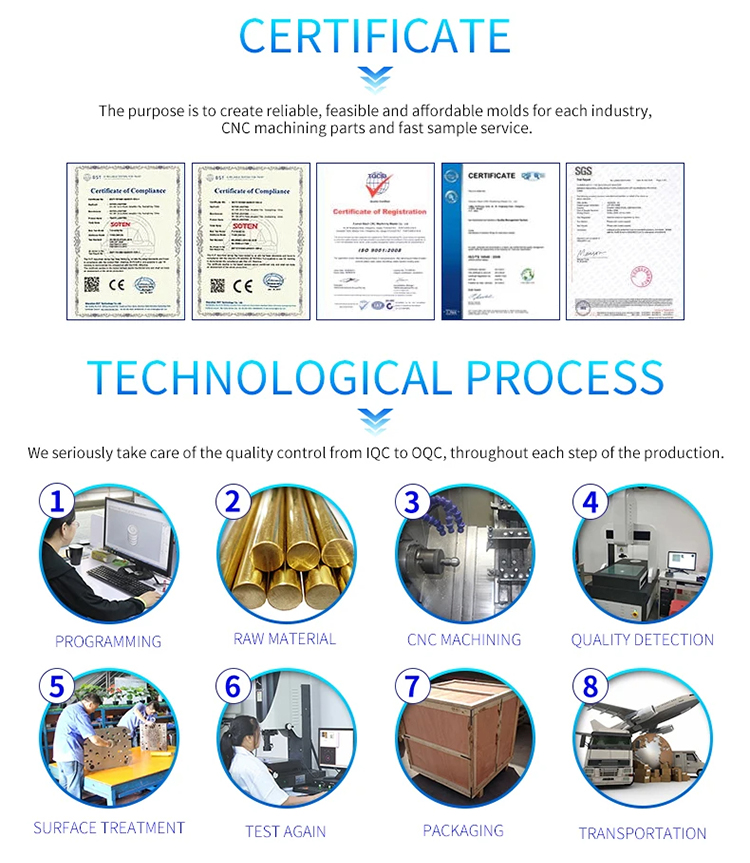

Quality is at the heart of everything we do at Chiheng Hardware Co., Ltd. Our strict quality control processes, from material selection to final inspection, guarantee that every turned aluminum part meets international standards. We employ cutting-edge measurement tools and techniques, such as CMM (Coordinate Measuring Machine) inspections, to ensure that each dimension is within the specified tolerance, and that the parts are free from defects.

Sustainability and Efficiency

We are committed to sustainable manufacturing practices. Aluminum is a recyclable material, and we optimize our processes to minimize waste, reduce energy consumption, and ensure that our operations are environmentally responsible. Our efficient production methods not only contribute to sustainability but also help us offer competitive pricing without compromising on quality.

Why Choose Chiheng Hardware Co., Ltd.?

Choosing Chiheng Hardware Co., Ltd. for your aluminum turning needs means partnering with a company that prioritizes precision, quality, and customer satisfaction. Our team of skilled machinists, engineers, and quality control specialists work together to deliver products that exceed expectations. We understand that each project is unique, and we are dedicated to providing customized solutions that meet your specific requirements.

At Chiheng Hardware Co., Ltd., we take pride in our ability to produce high-quality turned aluminum parts that serve as critical components in a wide range of applications. Whether you are developing a new product or improving an existing design, our expertise in aluminum turning will help you achieve your goals with precision and efficiency. Contact us today to discuss your project, and let us show you why we are the trusted partner for aluminum machining solutions.

Dongguan Chiheng Hardwrare Co.,Ltd is a professional OEM metal fabrication factory which is located in Chang'an, Dongguan, China,and specialize in this field since 2009.

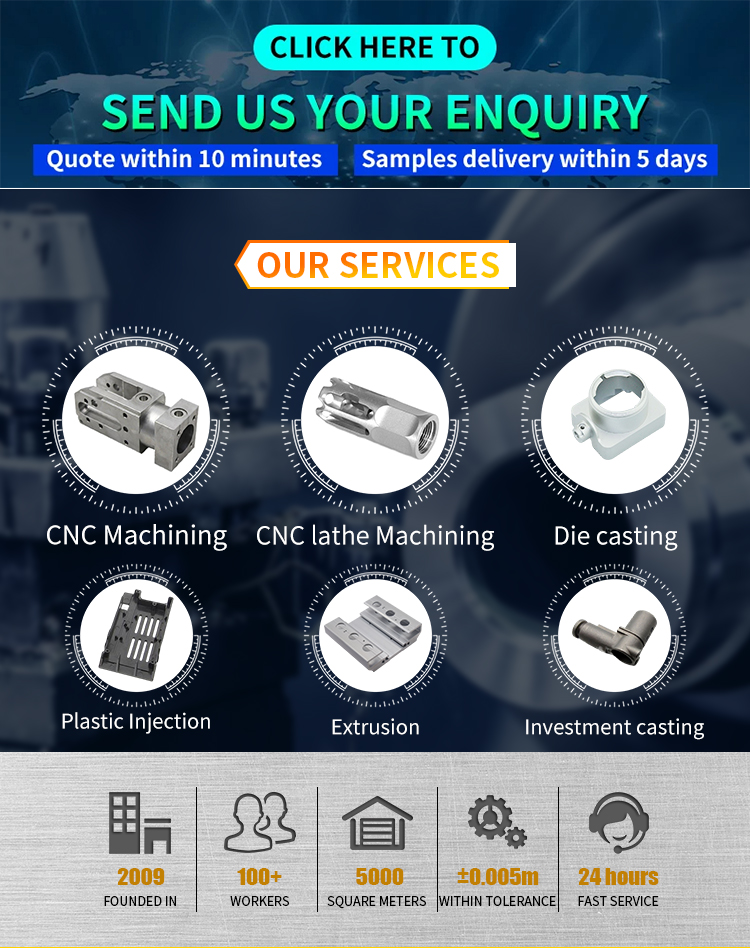

Our main business are CNC machining, plastic injection molding, die casting ,extrusion,Investment Casting and stamping parts.

We now have sophisticated CNC machining centers, engraving and drilling machine, Injection molding machine, stamping machine, compressor, lathe and milling machine, line cutting and other equipment.

With these machines and experienced employees, we are able to make repeated positioning accuracy within tolerance 0.005mm, providing strong guarantee for precision parts.

With great Service and nice quality,our products have been exported to USA, South America, Europe, Australia, Middle east and Southeast Asia, etc.Our goal is to make every customer happy.