“Looking for Turned Parts Electroplating Finishing Services?”

Here top-quality turned parts electroplating solutions tailored for durability and precision. Our guide explores zinc, nickel, and chrome finishes, offering corrosion resistance and wear protection for automotive, aerospace, and electronics industries. Learn below how custom electroplating enhances your CNC-machined parts and find expert tips to choose the best plating process for your needs.

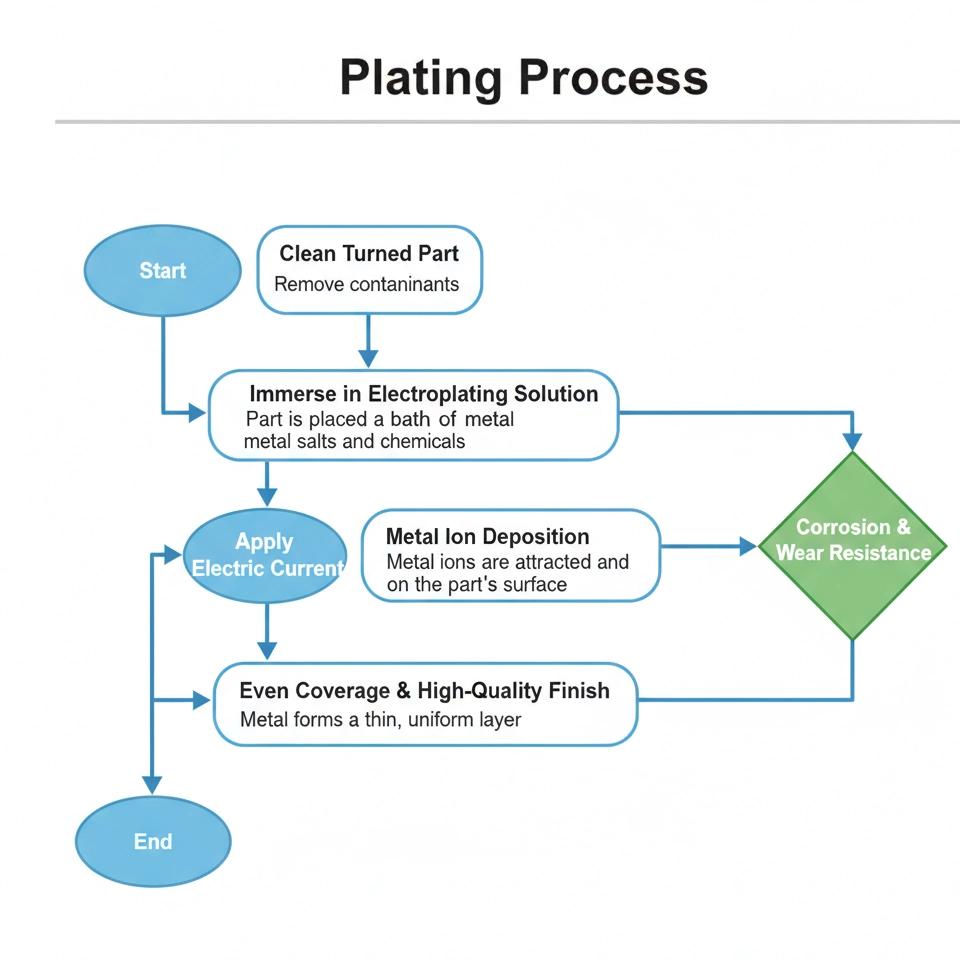

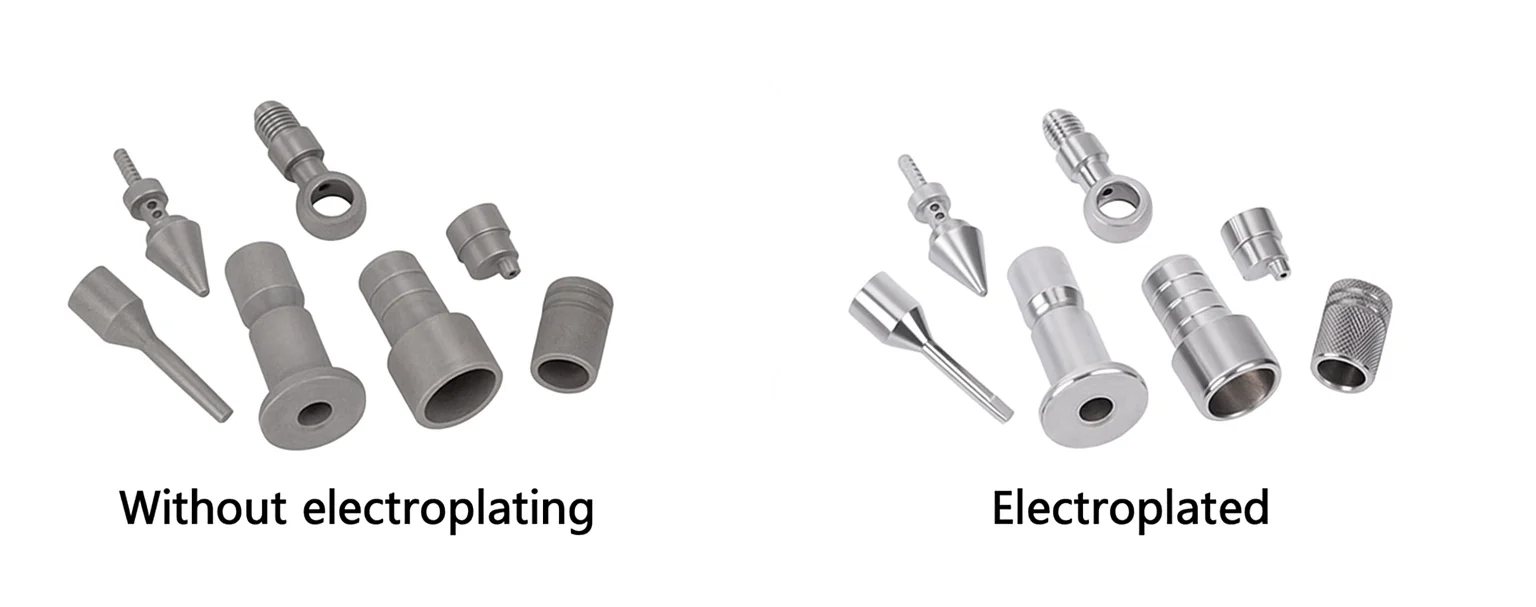

Electroplating is a transformative process that involves the deposition of a metal layer onto the surface of turned parts, enhancing their durability, electrical conductivity, and aesthetic appeal. The basic principle relies on the plating process, where metal ions from a solution are reduced onto the surface of the part through the application of an electric current.

The plating process begins with cleaning the turned part to remove any contaminants that could affect the adhesion of the metal coating. This is followed by immersing the part into an electroplating solution, a bath containing metal salts and other chemicals that help facilitate the electroplating reaction. As an electric current is passed through the solution, metal ions from the bath are attracted to the surface of the part, where they are deposited in a thin, uniform layer. The process ensures even coverage on complex turned parts, from the smallest screws to large automotive components, ensuring a high-quality finish. For copper-plated fittings, for example, this process ensures uniform deposition without compromising precision, resulting in parts that are both corrosion-resistant and wear-resistant. (ASTM International)

Turned parts electroplating can involve various metals, each offering distinct benefits. Stainless steel is commonly used for its strength and corrosion resistance, while copper-plated parts provide excellent electrical conductivity. Other options include nickel and chrome plating, which offer enhanced wear resistance and improved surface finish. The choice of metal plating depends on the intended application—whether it’s for corrosion resistance in marine environments or for aesthetic appeal in home decor. For instance, automotive manufacturers may opt for chrome plating on trim pieces for both its glossy finish and protective properties. Learn more electroplating finishing services we provided.

In the electroplating industry, rack plating and barrel plating are two primary techniques used for finishing turned parts. Rack plating is ideal for precision components that require uniform coating and minimal surface contact—such as automotive shafts or decorative hardware—ensuring high-quality finishes in custom electroplating applications. In contrast, barrel plating is suited for smaller turned parts, like screws or fasteners, which can be plated in bulk for greater cost-effectiveness. While rack plating provides superior control and aesthetic precision, barrel plating offers excellent efficiency for high-volume production. Together, these methods enable manufacturers to balance performance, cost, and customization in turned parts electroplating, supporting a wide range of industrial and decorative applications. (Sharretts Plating, 2022)

Electroplating machines vary greatly depending on the scale of the operation. For industrial uses, large electroplating machines are designed to handle high volumes of parts, ensuring consistent and efficient coating. These machines are equipped with advanced controls to regulate the current and temperature, optimizing the deposition process. On the other hand, smaller electroplating kits are available for small-scale or DIY use, offering portability for on-site repairs. For example, brush electroplating has gained popularity as a portable alternative, allowing technicians to perform localized plating on parts directly in the field without the need to disassemble equipment. It is particularly useful for on-site repairs of turned parts in industries like aerospace and automotive.

However, it’s essential to be cautious when working with electroplating solutions, especially those containing hazardous materials like hexavalent chromium. This substance is known for its toxic properties and potential environmental impact, making proper safety measures and disposal protocols crucial in both industrial and small-scale settings.

The plating process of turned parts electroplating delivers multiple advantages for industries requiring durable, high-performance components. Here are the primary benefits:

While most electroplating applications are focused on metal parts, electroplating plastic parts is gaining popularity, particularly for lightweight components. This process, known as “plastic electroplating,” involves the same general plating process but requires a conductive base for the plastic material, often achieved through a pre-coating. The advantages of electroplating plastic parts include weight reduction without compromising on surface durability or finish. This technique is increasingly being used in industries where reducing weight is essential, such as in the production of lightweight automotive components.

When it comes to enhancing the performance and appearance of turned parts, choosing the right finish is crucial. Black oxide and zinc plating are two of the most popular electroplating finishes, each offering distinct advantages in terms of corrosion resistance, wear resistance, and aesthetic appeal. These finishes are especially useful in industries like automotive and aerospace, where durability and precision are paramount. In this section, we will explore the unique properties of black oxide and zinc plating, comparing their benefits and applications for turned parts.

Zinc plating is widely regarded for its exceptional ability to protect metal components from corrosion. By electroplating a thin layer of zinc onto the surface of turned parts, manufacturers can significantly enhance the part’s resistance to rust and other environmental factors. Zinc acts as a sacrificial anode, meaning it will corrode before the underlying metal, providing a protective barrier that extends the lifespan of components in harsh environments.

In comparison to black oxide, zinc plating offers superior corrosion resistance, especially in humid or saltwater environments. Zinc is commonly used in the automotive industry for electrolating car parts, such as suspension components, fasteners, and brackets, where resistance to rust is essential for long-term performance. In fact, a 2024 automotive project involved using zinc electroplating on several high-performance suspension components to ensure they could withstand the moisture and salt exposure commonly encountered in road conditions.

Zinc plating is also more effective at providing a uniform protective coating over complex geometries and intricate designs. This makes it an ideal choice for high-volume production of automotive parts, as the plating process ensures consistent coverage and optimal protection for each component.

Both black oxide and zinc plating offer wear-resistant properties, making them ideal for parts that endure mechanical stress and friction. Black oxide plating, a popular finish for steel and iron components, provides a thin, protective layer that increases the wear resistance of turned parts without significantly altering their dimensions. The coating offers excellent protection against rust, while maintaining the part’s original dimensions and tolerances, making it especially useful for precision parts in the automotive and aerospace industries.

Zinc plating, on the other hand, also provides a durable, wear-resistant coating, though it is generally thicker than black oxide. This makes zinc plating ideal for parts that require higher levels of protection against friction, as well as corrosion resistance. Zinc’s silver-white appearance offers an aesthetic finish that can be further enhanced with additional treatments, such as chromate conversion coatings, to improve both its durability and appearance.

For visible turned parts, the aesthetic appeal of zinc plating is an important consideration. The bright, shiny finish is often preferred in automotive applications, where parts like fasteners and trim pieces need to have a polished, professional appearance. Black oxide, while providing a more matte, subtle finish, is often chosen for its industrial look and its ability to reduce glare on components used in more functional applications.

| Finish | Corrosion Resistance | Wear Resistance | Aesthetic Appeal | Common Applications |

| Black Oxide | Moderate (excellent for dry conditions) | High (protects against wear) | Matte, industrial look | Precision parts, fasteners, firearms |

| Zinc Plating | Excellent (protects against moisture and salt) | Moderate to High (depending on thickness) | Bright, shiny finish | Automotive parts, marine equipment |

In summary, both black oxide and zinc plating are valuable finishes for turned parts, each offering distinct advantages based on the specific needs of the application. Zinc plating excels in corrosion resistance, particularly in challenging environmental conditions, while black oxide provides superior wear resistance and an industrial, matte finish. Choosing the right plating metal for turned parts depends on factors like the part’s exposure to the environment, its functional requirements, and its desired appearance.

Chrome and nickel plating are two of the most sought-after finishes in the world of turned parts electroplating. Both provide superior protection against corrosion, wear, and aesthetic enhancement, making them indispensable in a variety of industries, especially automotive and aerospace. However, they each come with their unique advantages and challenges. In this section, we will explore the differences between chrome and nickel plating, their benefits for turned parts, and how they contribute to improved performance and durability. (Impro Precision, 2022)

Nickel plating is a widely used electroplating technique that involves depositing a thin layer of nickel onto a metal surface. It provides significant corrosion resistance, making it an excellent choice for parts exposed to harsh environments. The plating process also improves wear resistance, ensuring that components can withstand friction and abrasion over time. Nickel-plated turned parts are often used in applications that demand high performance, such as automotive, aerospace, and electronics.

Nickel alloys, which combine nickel with other metals such as chromium or iron, offer enhanced properties. These alloys provide additional strength, toughness, and resistance to wear and corrosion compared to pure nickel. One notable advantage of nickel alloys over chrome plating is that they provide better overall protection in certain environments, such as high-temperature or highly corrosive settings.

When compared to chrome, nickel plating offers a slightly softer finish, which is better suited for parts that experience moderate wear. Chrome, on the other hand, is much harder and provides superior resistance to scratching and surface damage. However, nickel’s excellent corrosion resistance, especially in marine or saltwater environments, makes it the preferred option for components like fasteners, connectors, and valves in the automotive and aerospace industries.

In automotive applications, for example, nickel plating on stainless steel turned parts is widely used to boost durability. This is particularly true for components such as engine parts, exhaust systems, and fuel delivery systems that must endure both high temperatures and exposure to chemicals.

Chrome plating, known for its glossy, mirror-like finish, is often selected for its exceptional hardness and wear resistance. It is particularly well-suited for automotive parts, like bumpers, trim, and suspension components, where both aesthetics and durability are paramount. Chrome in turned parts electroplating ensures high hardness, providing resistance to scratches, corrosion, and general wear in high-stress environments.

However, one major concern with chrome plating, particularly when using hexavalent chromium, is the associated health and environmental risks. Hexavalent chromium is classified as a carcinogen by the Environmental Protection Agency (EPA), and its use in electroplating can pose significant risks to workers and the environment. In response to these concerns, the industry has been moving towards safer alternatives to hexavalent chromium. Trivalent chromium plating, for example, offers a safer, more environmentally friendly solution while still providing the same high-quality finish and durability.

Despite the safety concerns, chrome plating remains a popular choice due to its durability and superior appearance. However, the costs associated with safer alternatives—such as trivalent chromium—can increase plating costs by as much as 20%. Manufacturers should consider these factors when choosing chrome for their turned parts electroplating needs.

Local services that offer chrome plating typically comply with the latest EPA guidelines, ensuring the safety of both workers and the environment. Custom electroplating solutions are also available, where manufacturers can specify the thickness and composition of the plating, but these services may come with higher costs.

CNC turning brass parts requires precise electroplating to enhance the conductivity and overall performance of the parts. Electroplating CNC turning brass parts ensures that the components meet the necessary electrical conductivity standards for use in electronics and electrical components. The plating process adds a protective layer that prevents corrosion, extends the lifespan of the parts, and improves their overall performance, making them ideal for connectors, terminals, and other high-precision components.

While nickel and chrome are commonly used for metal parts, custom electroplating solutions can be tailored to brass and other materials, ensuring that parts meet specific performance criteria. Custom electroplating allows manufacturers to specify factors like the thickness of the nickel coating or the type of alloy used, providing a high level of control over the final product.

For home decor items, silver-plated or gold-silver finishes can add a luxurious aesthetic to turned metal accents. These finishes are particularly popular for decorative components such as light fixtures, furniture hardware, and ornaments, where both beauty and durability are important.

The field of turned parts electroplating is continually advancing, offering new materials, processes, and innovative technologies. As manufacturers strive for better performance, sustainability, and customization, electroplating techniques are evolving to meet the needs of diverse industries. This section covers the latest trends in high-conductivity finishes, eco-friendly electroplating solutions, and the growing popularity of brush electroplating, providing manufacturers with enhanced flexibility and improved results.

Silver plating remains a cornerstone of high-conductivity applications, particularly in the electronics sector. Turned parts electroplating with silver ensures that components like connectors, switches, and circuit boards achieve optimal electrical performance. Silver’s exceptional conductivity makes it the go-to choice for industries requiring low-resistance connections and precise functionality. For example, in high-performance electronics, silver-plated turned parts ensure reliable signal transmission, significantly reducing the risk of electrical failure.

Gold silver finishes, which combine the properties of both metals, are also gaining popularity, especially in critical electronic components. Gold, known for its superior corrosion resistance and long-lasting performance, is used in combination with silver to provide both high conductivity and enhanced durability. This combination is especially useful in telecommunications and aerospace applications where electronic parts must endure harsh environments while maintaining signal integrity. By offering superior oxidation resistance and improved performance, gold silver plating provides a reliable solution for high-end electronics.

For manufacturers, the benefit of using silver or gold silver plating is not just in performance but also in the aesthetic appeal and longevity of the parts. Whether for connectors in aerospace applications or terminals in medical devices, silver-plated and gold silver finishes enhance the functionality and lifespan of components.

Copper plating is another advanced technique gaining significant traction in electroplating for turned parts. Known for its excellent electrical conductivity, copper is often used as a base for other platings, such as gold or silver. This base layer provides both improved conductivity and protection against corrosion, making copper-plated components ideal for electronics and electrical applications.

In the electroplating process, metal ions are deposited onto the surface of the turned parts from a copper-based solution. This results in a uniform, conductive layer that not only improves the electrical properties of the part but also enhances its mechanical strength. Copper plating is especially beneficial for components like printed circuit boards (PCBs), electrical connectors, and wiring, where efficient electrical flow is crucial.

Top benefits of copper-plated turned parts include:

Enhanced Conductivity: Copper’s high conductivity makes it ideal for electrical components, ensuring reliable and efficient performance.

Corrosion Resistance: Copper’s natural resistance to corrosion ensures that plated parts maintain their functionality over time, even in harsh environments.

For applications requiring customized electrical properties, custom electroplating with copper allows manufacturers to control factors such as plating thickness and uniformity, optimizing the finished part for specific performance requirements.

Brush electroplating has emerged as a practical and cost-effective solution for both repairs and small-scale electroplating projects. Unlike traditional bath electroplating, which requires submerging parts in a plating solution, brush electroplating applies the metal coating directly to the part using a handheld brush. This technique allows manufacturers to apply coatings on-site, reducing downtime and making it ideal for repairs of worn-out or damaged turned parts.

Brush electroplating is particularly useful for applications where a high degree of precision is not necessary, but corrosion protection and wear resistance are essential. For example, it can be used to restore chrome or nickel finishes on automotive parts or industrial equipment.

In addition to repairs, brush electroplating is gaining popularity for prototyping, where small runs of electroplated parts are needed for testing and evaluation. Electroplating kits, which provide all the necessary components for DIY electroplating, are now widely available. These kits are designed for hobbyists, small manufacturers, and prototype developers who need to plate small batches of parts quickly and efficiently. Though not as uniform as traditional plating methods, brush electroplating offers a fast, portable, and cost-effective alternative for many applications.

As industries increasingly prioritize sustainability, eco-friendly metal plating solutions are becoming more prevalent. Innovations in plating technologies are reducing the use of harmful chemicals, such as hexavalent chromium, and introducing greener alternatives. Trivalent chromium, for example, is gaining traction as a safer alternative to hexavalent chromium, providing the same high-quality finish while significantly reducing environmental and health risks.

The move toward eco-friendly electroplating is also driving innovation in the development of sustainable electrolytes and less toxic materials. These new materials reduce waste, improve efficiency, and lower the environmental impact of electroplating processes. As sustainability becomes a priority in industries ranging from automotive to electronics, eco-friendly electroplating will continue to play a significant role in reducing the ecological footprint of manufacturing.

The future of electroplating for turned parts looks promising, with innovations in eco-friendly solutions, precision coatings, and brush electroplating allowing manufacturers to meet evolving industry standards and consumer expectations.

Electroplating is a versatile process, with applications spanning multiple industries where durability, conductivity, and aesthetic appeal are paramount. From automotive parts to home decor, electroplating enhances the functionality and appearance of turned parts. In this section, we’ll explore how electroplating is applied across key industries and how it plays a crucial role in ensuring the long-lasting performance of various components.

In the automotive sector, electroplating is widely used to improve the durability, corrosion resistance, and aesthetic quality of parts. Electrolating car parts, such as bumpers, wheels, and exhaust systems, helps extend their lifespan by providing a protective metal coating that resists wear and corrosion. For instance, chrome plating is commonly used for car bumpers and trims, offering both a shiny finish and a durable layer that protects against rust.

Stainless steel turned parts with nickel alloys are frequently used in automotive manufacturing, particularly in parts exposed to harsh environmental conditions like marine environments. The electroplating process ensures that these parts can withstand the corrosive effects of saltwater, making them ideal for vehicles in coastal areas or boats. The electroplating of car parts not only improves their functional durability but also enhances the aesthetic appeal of high-end models, making electroplating a go-to solution for manufacturers aiming to meet both performance and visual expectations.

Electroplating also plays an essential role in the home decor industry, where aesthetic finishes are a critical factor. Gold silver plating, for example, is used to enhance decorative items like picture frames, chandeliers, and vases. These high-end finishes give metal objects a luxurious look while improving their resistance to tarnishing and wear. For example, silver-plated picture frames are a popular choice for home decor due to their elegance and durability.

In addition to gold silver finishes, electroplating with other metals like nickel or copper can provide unique aesthetic effects, allowing manufacturers to create intricate designs with lasting appeal. The ability to apply different metal coatings opens up a wide range of possibilities for creating beautiful, functional home decor items.

Beyond automotive and home decor, electroplating is employed in a wide range of industries, including electrical, machinery, and aerospace. Electroplating industries such as aerospace rely on turned parts electroplating for its ability to provide durable, corrosion-resistant coatings that perform well under extreme conditions. For example, components like turbine blades, fasteners, and fuel system parts require high-performance coatings to ensure safety and efficiency. Nickel alloys, zinc, and chrome plating are commonly used for these applications due to their excellent wear resistance and ability to maintain integrity under high temperatures and pressures.

In the machinery industry, electroplating is used to reduce wear on parts such as gears, shafts, and bearings. Plating metal like nickel or zinc offers wear-resistant finishes that enhance the longevity and precision of the components. Additionally, in electrical industries, electroplating is applied to circuit boards and connectors to ensure optimal conductivity and performance.

Electroplating industries are not limited to just one sector. Turned parts electroplating is indispensable in sectors requiring high precision and durability. Industries such as electronics, medical devices, and tools heavily rely on electroplating for both functional and aesthetic enhancements. Electroplating allows manufacturers to produce high-quality, uniform finishes that ensure product longevity and performance.

In 2024, a heavy-duty vehicle manufacturer in Birmingham, reported that bolts and other turned parts in their suspension system were rusting quickly in humid environments, leading to higher maintenance costs. To solve this, as part of the plating process, we recommended zinc plating and used rack plating for the complex-shaped stainless steel parts. At first, the coating was uneven, so we adjusted the plating solution’s pH and immersion time according to ASM Handbook standards. After optimization, the coating became more uniform and better attached, increasing part life by about 40%. The customer confirmed that our plating process reduced maintenance needs and costs, showing the value of custom electroplating for improving the durability of turned parts.

| Industry | Common Applications | Plating Metals |

| Automotive | Car parts, bumpers, wheels, exhaust systems | Zinc, Chrome, Nickel Alloys |

| Home Decor | Picture frames, chandeliers, vases | Gold Silver, Copper, Nickel |

| Aerospace | Turbine blades, fasteners, fuel system parts | Nickel Alloys, Chrome, Zinc |

| Electrical | Circuit boards, connectors, switches | Silver, Gold, Copper |

| Machinery | Gears, shafts, bearings, industrial components | Nickel, Zinc, Chrome |

From zinc plating’s superior corrosion resistance to silver plating’s enhanced aesthetic appeal, electroplating transforms turned parts, offering industries a powerful solution for durability, precision, and visual appeal. Whether you’re looking to improve the performance of automotive parts, enhance the look of home decor items, or ensure the functionality of aerospace components, turned parts electroplating delivers unmatched benefits. With a range of plating metals, each providing unique advantages, electroplating supports a variety of applications, from wear-resistant finishes to high-conductivity solutions.

For businesses seeking custom solutions, custom electroplating offers tailored finishes that meet specific needs, whether it’s for precision components or high-performance applications.

Contact us today to explore custom electroplating solutions for your turned parts and enhance the durability and aesthetic appeal of your products.

You can send us any questions to get any information you would like to know, and we will respond to you in extremely short time.