Description

Why Choose Our Compression Molding Solutions?

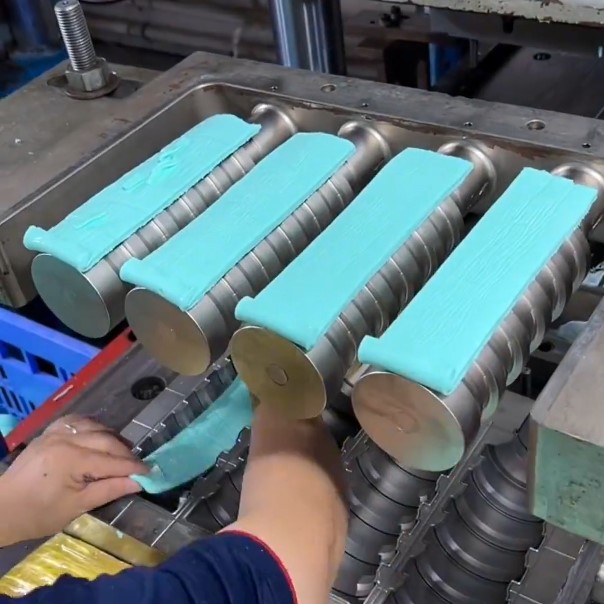

Rapid Prototyping & High-Volume Production

Prototype in 7 Days: Submit your design files and get functional samples fast.

Scale to 100,000+ Units: Optimized press molding process for cost-effective mass production.

Material Expertise You Can Trust

Thermoset Plastics: Phenolic, Epoxy, DAP (custom formulations for electrical insulation and structural stability).

Advanced Composites: Fiber-reinforced plastics (glass/carbon fiber), ceramic-filled polymers (wear resistance).

Specialty Materials: High-performance thermoplastics (PEEK, PA6), bio-based polymers (PLA, PHA).

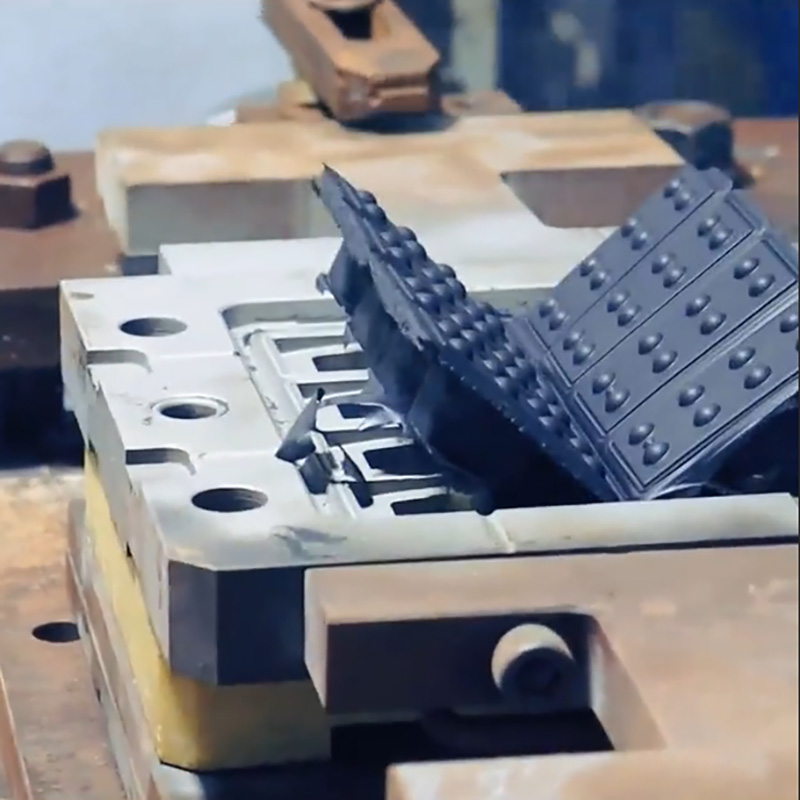

How to ensure the uniform filling of materials during compression molding?

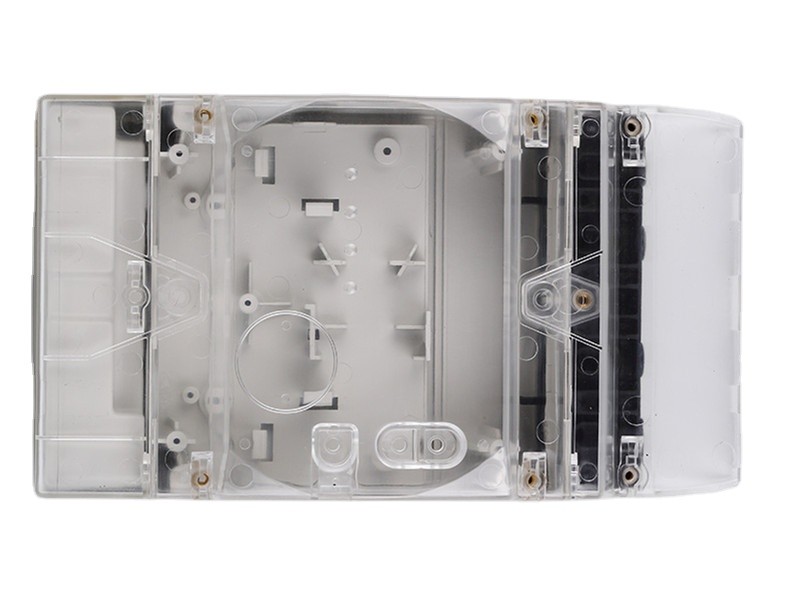

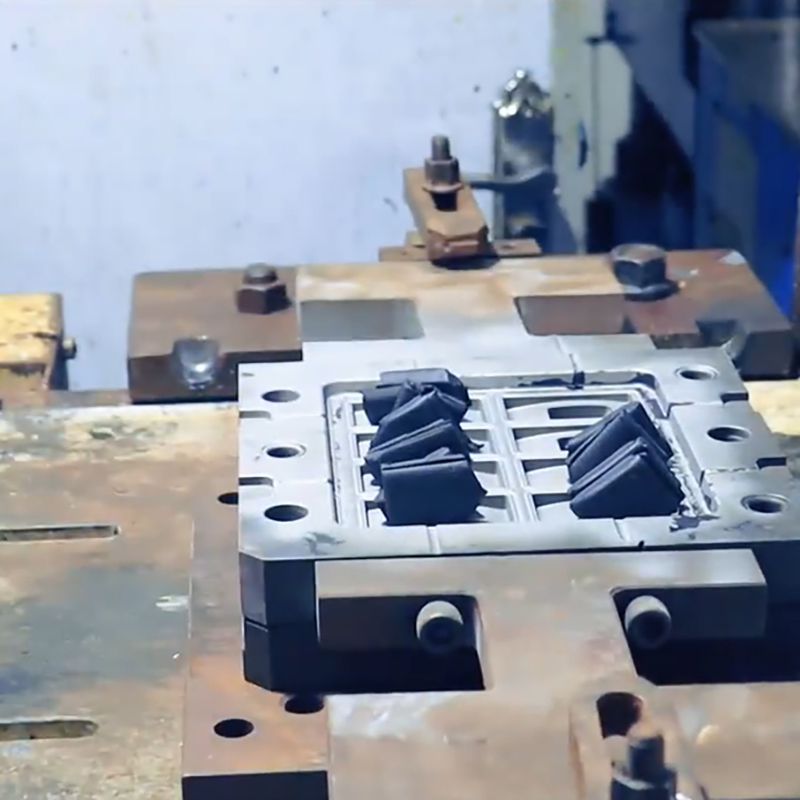

Advanced Compression Molding Capabilities

Materials We Support

- Silicone Molding: Liquid Silicone (LSR), Solid Silicone (high-temperature and medical-grade options).

- Metal-Powder Composites: Copper/iron-based mixes for EMI shielding and thermal management.

- High-Strength Polymers: PTFE, PPS (chemical resistance, low friction).

Precision Engineering

- Tolerance as tight as ±0.005 mm

- Multi-cavity mold design support

- Secondary services: Trimming, Bonding, QC Inspection

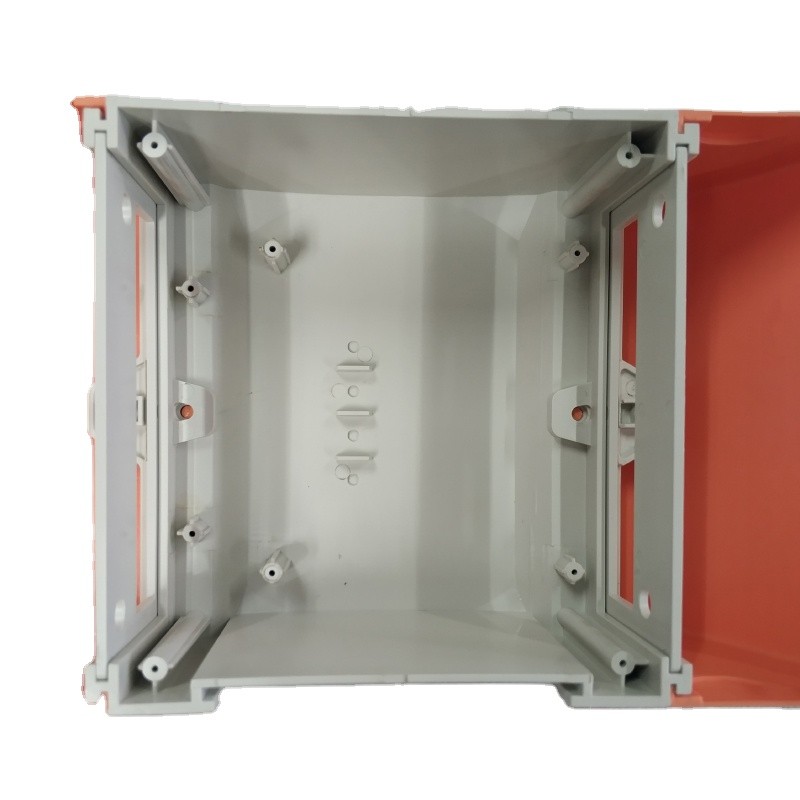

Industry-Proven Compression Molding Applications

Electronics Encapsulation

● Product Example: Epoxy-encapsulated sensors, DAP insulators.

● Benefits: IP67 protection, dimensional stability under thermal cycling.

Industrial Component Manufacturing

● Product Example: Carbon-fiber reinforced bushings, PEEK thrust washers.

● Benefits: 30% weight reduction vs. metal, corrosion resistance.

Medical Device Components

● Product Example: LSR respiratory masks, biocompatible PHA surgical tool housings.

● Benefits: USP Class VI, ISO 13485, and ASTM F640 compliance.

Compression Molding FAQs

● Can you handle small-batch orders?

Yes! We support prototypes (20-100 units) to high-volume production.

● What is the typical lead time for compression molding projects?

Prototypes: 7-10 days after mold approval.

Mass Production: 3-5 weeks (including tooling and material preparation).

Need it faster? Ask about our expedited service!

● How durable are compression molding tools (molds)?

Standard Molds: 100,000-500,000 cycles (steel molds).

Maintenance: Free mold inspection every 50,000 cycles to ensure longevity.

We provide mold storage services for repeat orders.

● Can you help with material selection for my project?

Yes! Our engineers will analyze your requirements (temperature, chemical exposure, etc.) and recommend cost-effective materials.

Free material testing reports for orders over 10,000 units.

● What file formats do you accept for mold design?

Preferred Formats: STEP, IGES, SolidWorks (.sldprt).

Legacy Formats: AutoCAD (.dwg) and PDF sketches (with dimensions).

Need design help? Use our $99 DFM (Design for Manufacturing) review service.