Description

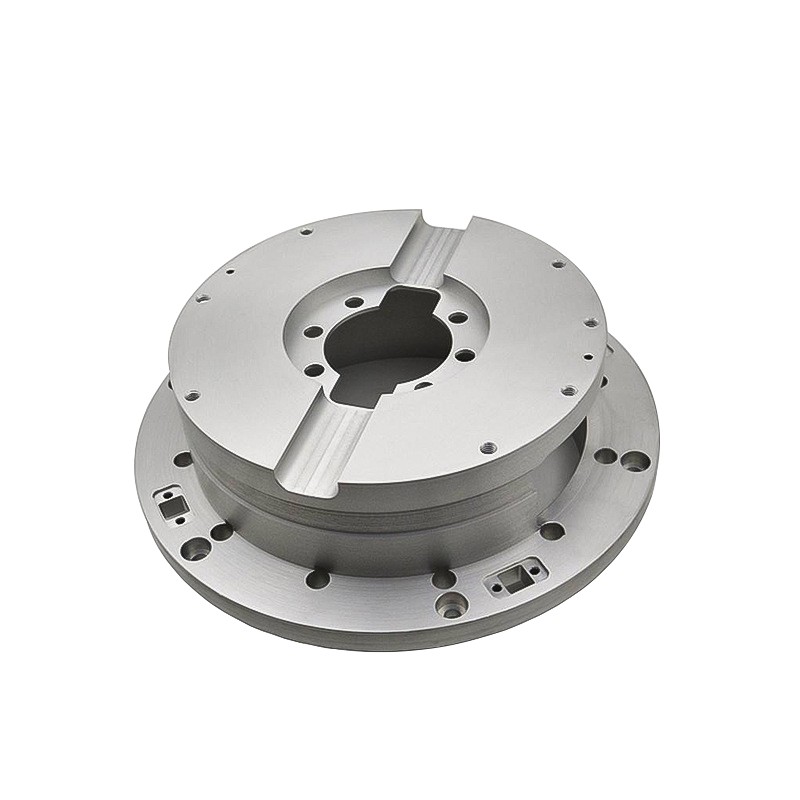

Mold Material :Metal and Plastic

Chiheng offers a comprehensive range of surface finish services, including anodizing, brushing, galvanizing, laser engraving, plating, polishing, powder coating, sandblasting, and silk printing. These services are designed to enhance the appearance, durability, and functionality of our turn mill products. By providing diverse surface treatment options, we ensure that our turn mill components meet the highest standards of quality and aesthetics, catering to the specific needs and preferences of our customers.

Cavity : Single or multiple

Product Material:

1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24

2) Zinc alloy 3#, 5#, 8#

Surface Treatment:

1) Polish, powder coating, lacquer coating, e-coating, sand blast, shot blast, anodine2) Polish + zinc plating/chrome plating/pearl chrome plating/nickel plating/copper plating

Size:

1) According to customers' drawings

2) According to customers' sample

Drawing Format:step, dwg, igs, pdf

Certificates :ISO 9001:2015 & IATF 16949

Payment Term : T/T, L/C, Trade Assurance

-

Packaging Details:

1. With plastic bag,with pearl-cotton package.

2. To be packed in cartons.

3. Use glues tape to seal cartons.

4. Deliver out by sea or air.

Or according to customers' requirement.

Each carton less than 15kg.

-

HK or Shenzhen

Understanding the Drill Press and Cross Vise

As an experienced machinist. One of the most versatile and cost-effective tools in my arsenal is the humble drill press, combined with a trusty cross vise.The drill press is a versatile machine tool that can be used for a variety of tasks, including drilling, reaming, and, as we'll explore, milling aluminum. The cross vise, on the other hand, is a crucial accessory that allows for precise positioning and control of the workpiece during the milling process.

Drill Press: This powerful tool features a vertical spindle that can accommodate a wide range of drill bits and end mills. The drill press offers excellent control over the depth of cut and the ability to create consistent, accurate holes and slots.

Cross Vise: The cross vise is a specialized workholding device that mounts directly to the drill press table. It allows for precise movement and positioning of the workpiece in both the X and Y axes, enabling you to create intricate milled features with ease.

Selecting the Right End Mill for Aluminum Milling

The choice of end mill is crucial when milling aluminum. The right tool can make all the difference in achieving a smooth, consistent finish and prolonging the life of your cutting edges. Consider the following factors when selecting an end mill:Flute count: Higher flute counts (3-4 flutes) tend to work best for aluminum, as they provide efficient chip evacuation and improved surface finish.

Coating: Coated end mills, such as those with titanium nitride (TiN) or diamond-like carbon (DLC) coatings, can offer enhanced wear resistance and extended tool life.

Geometry: End mills with a positive rake angle and a sharp cutting edge are well-suited for aluminum machining, as they minimize the risk of built-up edge formation.