Description

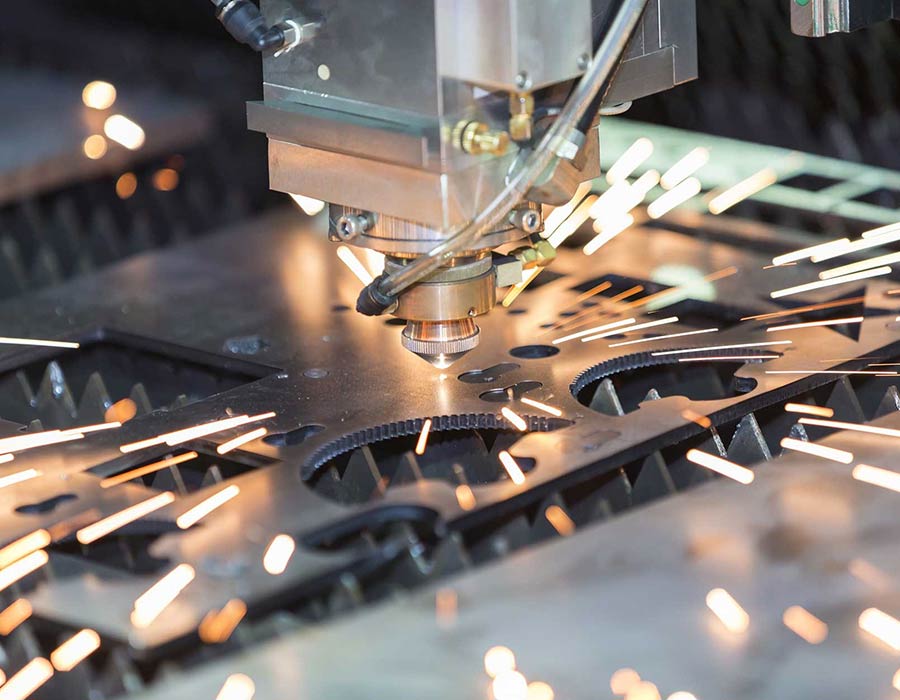

Our Laser Cutting Capabilities

Our state-of-the-art laser cutting service offers unparalleled precision and versatility for your manufacturing needs. Utilizing advanced CNC-controlled lasers, we can effortlessly cut through a wide range of materials, including metals, plastics, and composites, with exceptional accuracy and speed.

Our laser cutting technology enables:

Intricate designs with tight tolerances

Clean, smooth edges requiring minimal post-processing

Rapid prototyping and production runs

Cost-effective processing for both small and large batches

Whether you need custom parts for aerospace, automotive, electronics, or any other industry, our laser cutting service delivers superior results. Our experienced technicians ensure each project meets the highest quality standards, providing you with components that perfectly match your specifications.

Our Laser Cut Part Gallery

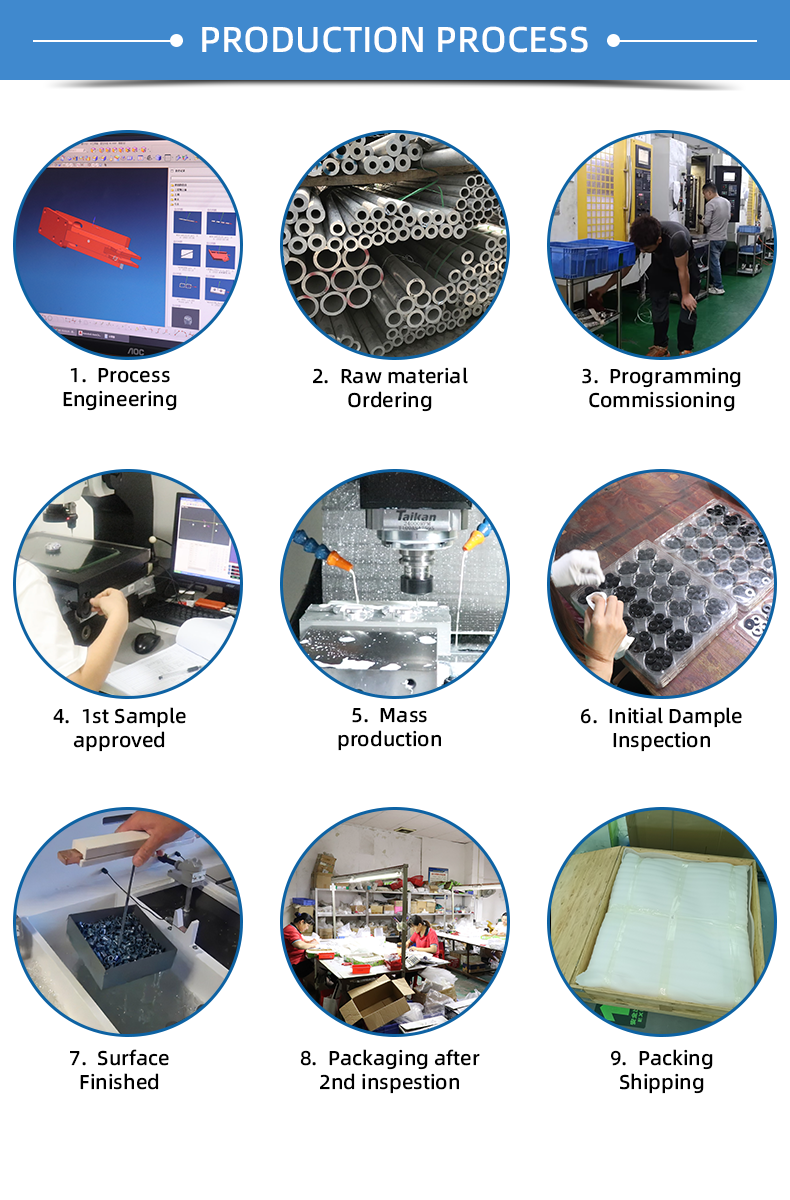

Dongguan Chiheng Hardwrare Co.,Ltd is a professional OEM metal fabrication factory which is located in Chang'an, Dongguan, China,and specialize in this field since 2009.

Our main business are CNC machining, plastic injection molding, die casting ,extrusion,Investment Casting and stamping parts.

We now have sophisticated CNC machining centers, engraving and drilling machine, lathe and milling machine, line cutting and other equipment.

With these machines and experienced employees, we are able to make repeated positioning accuracy within tolerance 0.005mm, providing strong guarantee for precision parts.

With great Service and nice quality,our products have been exported to USA, South America, Europe, Australia, Middle east and Southeast Asia, etc.Our goal is to make every customer happy.

-

Do you conduct quality inspections in your factory? Will you provide a quality inspection report with all measurements?

Yes, we have a comprehensive quality inspection process in place. We can provide detailed testing reports upon request, including all necessary measurements.

-

What is the average delivery time?

For samples, the typical delivery time is approximately 7-10 days.

For mass production, the delivery time ranges from 10 to 20 days, depending on the order quantity and complexity of processing. -

What is your minimum order quantity (MOQ)?

We do not have a strict minimum order quantity. We welcome orders for prototypes as a trial.

-

What types of equipment do you utilize?

Our facility is equipped with advanced CNC machining centers, CNC turning lathes, CNC drilling machines, CNC milling machines, stamping equipment, and welding machinery. Our highly skilled engineers can manufacture products according to your specifications or samples.

-

Are your materials ROHS compliant?

Yes, all materials used are compliant with ROHS certification standards.

-

Will your company sign a Non-Disclosure Agreement (NDA)?

Absolutely. We are willing to sign an NDA prior to receiving your drawings or design specifications to ensure confidentiality.

-

What are your machining tolerances and surface roughness capabilities?

We can achieve tolerances of ±0.005 to ±0.01 mm and surface roughness levels ranging from Ra 0.6 to Ra 3.2.

-

How does your factory ensure quality control?

Our experienced engineers oversee every stage of the manufacturing process, utilizing various advanced testing equipment, including but not limited to Coordinate Measuring Systems, Ultrasonic Testers, and Imaging Spectrometers to detect and minimize defects.

-

How do you handle faulty products?

Our products are manufactured under a strict quality control system with 100% inspection before shipment.

We prepare an additional 2% of spare parts for each order as replacements.

During the warranty period, if any defective parts are identified due to quality issues, we will send replacement parts at no cost.

For more complex issues, we will communicate directly with customers to find the best solution.