Comprehensive CNC Machining Services

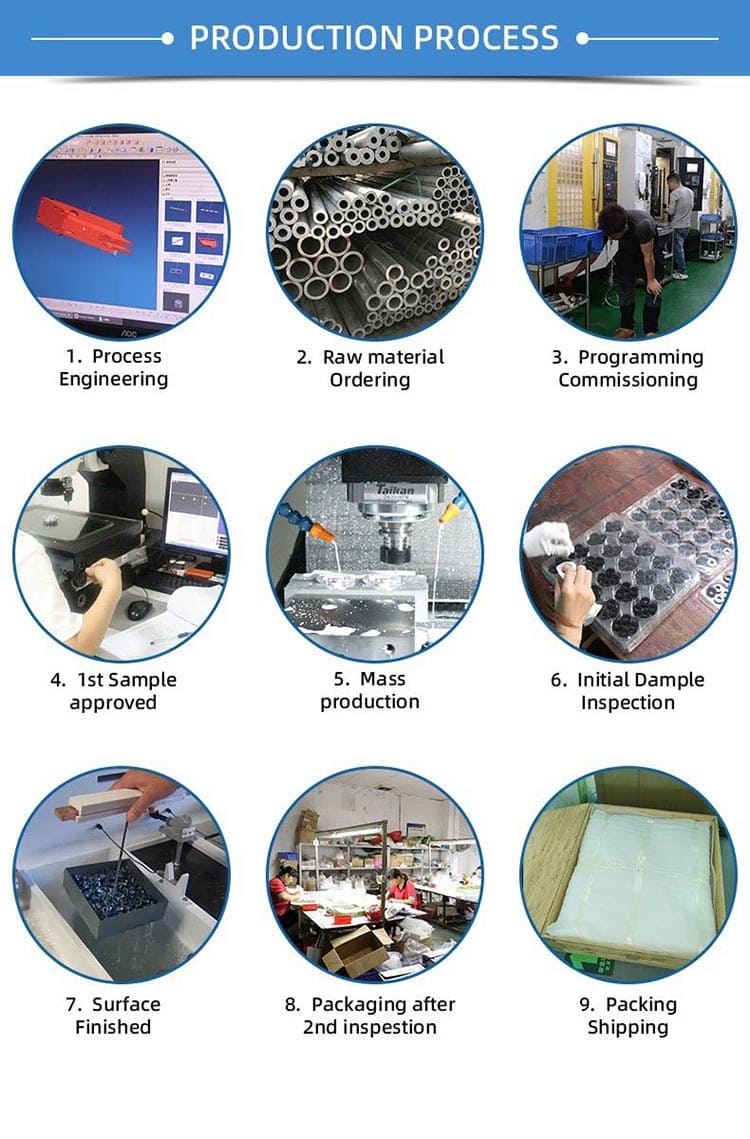

CNC Milling Services:

- Surface leveling and finishing

- Custom depth control

- Precision slot milling

- Connection holes and thread milling for assembly integration

CNC Turning Services:

- Max capacity: 320mm diameter x 200mm length

- Specialized in bar stock and tube processing

- Operations include drilling, groove milling, threading, and knurling

- Precision cylindrical part manufacturing

Bending Services:

Our bending services offer precise shaping of metal components, allowing for complex geometries and angles.

Drilling Services:

- Straight and angular hole drilling

- Diameter range: 1mm to custom specs

- Material-specific drilling capabilities

Tapping Services:

- Thread standards:

* Metric

* Whitworth

* Pipe

- Minimum size: M1.0

- Custom threading based on specs

Value-adding Services:

- Services include:

* Assembly

* Packaging

* Logistics

* One-stop solutions

Other Services

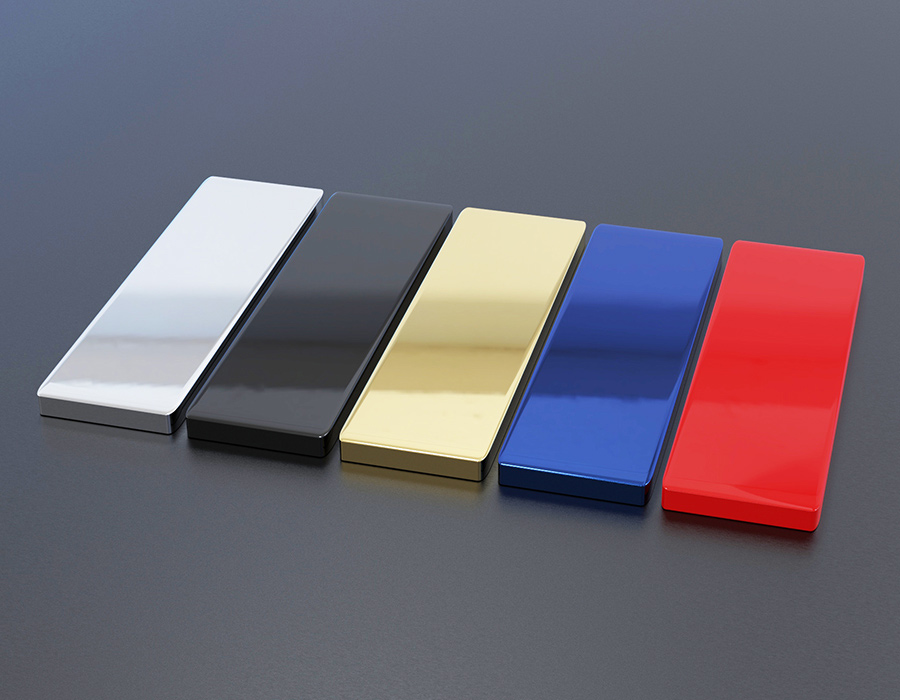

Materials SelectionWe offer surface treatments such as anodizing, sandblasting, and powder coating.

Materials SelectionWe offer surface treatments such as anodizing, sandblasting, and powder coating. Surface FinishAccess our library of 50+ metals and plastics for your CNC machining needs.

Surface FinishAccess our library of 50+ metals and plastics for your CNC machining needs.

Why You Can Trust Chihenghardware

- Strictly adhere to ISO 9001:2015 quality management standards, dedicating ourselves to delivering top-quality CNC machined parts.

- Operate as a professional CNC machining supplier and experienced CNC machining parts manufacturer.

- Leverage advanced production technology and rigorous internal quality control to ensure every custom machining project precisely meets your specifications.

- Strive to provide precision machining services that consistently exceed expectations, establishing ourselves as your truly reliable partner.

Extensive Industry Experience

With years of specialized service machining experience, we cater to a diverse global clientele across numerous industries. Our skilled engineering team excels at complex designs and demanding tolerances, understanding the high standards required by leading production machining companies. We're committed to providing you with the optimal manufacturing solutions.

Advanced Machining Capabilities

Our facility is equipped with multiple state-of-the-art CNC machining centers, turn-mill complexes, and advanced inspection instruments. This investment empowers us to efficiently and accurately produce a vast range of metal and plastic components. Whether you require low-volume prototypes or high-volume production runs, our comprehensive cnc machining services are ready to meet the challenge.

One-Stop Service Solution

From rapid quotations and expert DFM (Design for Manufacturability) feedback to material sourcing, precision CNC processing, meticulous quality checks, and dependable logistics, we offer end-to-end custom machining solutions. Acting as your reliable cnc machining supplier, we simplify the entire process, delivering significant savings in time and management overhead for you.

ISO 9001 Certified

Quality you can trust, backed by ISO 9001 certification with comprehensive material certific

Rapid Production & Quick-Turn Manufacturing

• 24-hour material selection and manufacturing analysis

• Fast-track production parts service available

• Comprehensive quality assurance on all rapid prototypes

• 10-day standard production with expedited options

-

How does precision CNC machining improve product quality?

Precision CNC machining enhances product quality by providing exceptional accuracy and repeatability. Using advanced CNC technology, we can achieve tight tolerances down to ±0.0002 inches (5μm). This ensures that each part meets exact specifications, reducing errors and improving overall functionality.

-

What materials are suitable for precision CNC machining?

Precision CNC machining is versatile and can handle a wide range of materials, including metals like aluminum, brass, copper, steel, titanium, and zinc. Additionally, it is compatible with non-metals such as plastics and fiberglass.

-

Why choose CNC machining for high-volume production?

CNC machining is ideal for high-volume production due to its scalability and efficiency. Once programmed, CNC machines can produce large quantities of parts with consistent quality and minimal variation.

-

How does CNC machining ensure complex part geometries?

CNC machining excels in creating complex part geometries through its multi-axis capabilities. With 3-axis, 4-axis, and 5-axis machines, we can perform intricate operations that would be challenging with traditional methods.

-

What are the benefits of using CNC machining over manual processes?

CNC machining offers several advantages over manual processes, including increased precision, reduced human error, and faster production times.

-

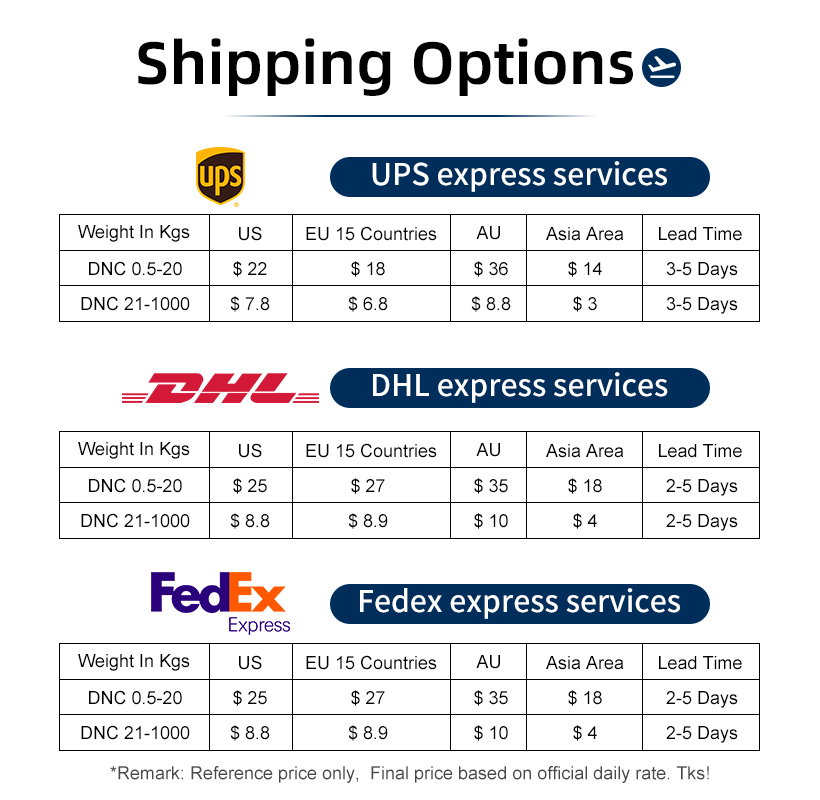

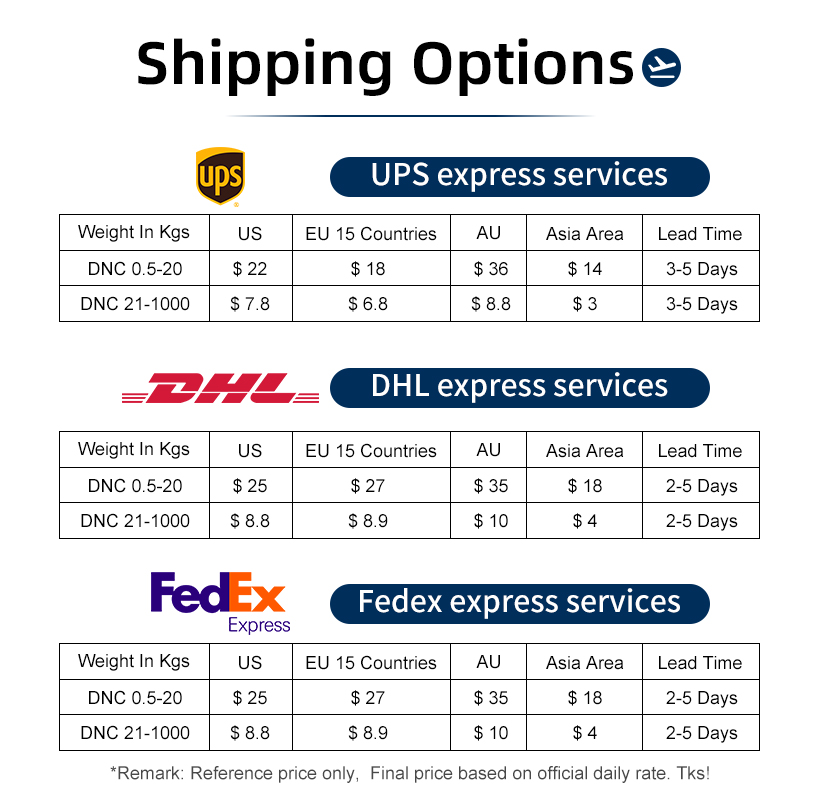

How can I be sure that your shipping fees are competitive?

We offer transparent pricing and provide detailed shipping quotes upfront. We also work closely with our customers to identify the most cost-effective shipping solution.