| Material | 1045 Carbon Steel |

| Processing | Milling, Turning, Cutting, Welding |

| Finish | Multiple options |

| Advantages | excellent strength, heat-treating properties, and impact resistance |

At Chiheng Hardware, we specialize in 1045F medium carbon steel machining services, offering high-quality, precision-machined components for a variety of industries. 1045F Steel is an enhanced version of 1045 carbon steel, treated for improved machinability, making it an excellent choice for applications requiring tight tolerances and intricate designs.

The 1045F carbon steel ventilated brake disc is crafted through a series of precise manufacturing steps to ensure top-notch performance and durability. Here’s a breakdown of the key processes involved:

The initial shape of the brake disc is created through a casting process. The 1045F carbon steel is melted and poured into molds. After cooling, the rough disc shape is formed. This is the first stage of production, providing the foundation for further refinement.

Once cast, the brake disc undergoes turning on CNC (computer numerical control) or traditional lathes to refine its shape. This step ensures the surface is smooth and the disc meets precise size specifications. The disc’s thickness is also adjusted to ensure compatibility with the braking system.

To enhance the disc’s heat dissipation performance, small holes are drilled into the surface. These perforations help cool the disc during braking, reducing heat buildup. The precise arrangement and size of these holes are critical for performance, ensuring proper airflow and cooling.

After the initial machining, the brake disc undergoes heat treatment, including processes like quenching and tempering. These methods increase the hardness and wear resistance of the 1045F carbon steel, ensuring the brake disc performs well over time under high-stress conditions.

Finally, the brake disc is finished through additional processes such as fine turning, grinding, or polishing. These final steps ensure the surface is smooth and free of imperfections, optimizing both performance and aesthetic quality.

1045F carbon steel brake discs are designed to deliver superior performance in terms of strength, durability, and heat dissipation. Whether you’re in need of high-performance braking systems for heavy-duty applications or simply seeking reliability in standard use, these brake discs offer the ideal combination of toughness and efficiency.

1045F steel is a variation of 1045 carbon steel that has undergone a free cutting treatment. The “F” designation refers to the addition of elements like sulfur and lead, which improve its machinability. These elements reduce tool wear and improve cutting performance, allowing for faster, more efficient machining processes. As a result, 1045F steel is often used in applications where high-precision cutting and tight tolerances are essential.

Though it shares many of the mechanical properties of 1045 carbon steel, 1045F steel stands out for its superior ability to be machined with high precision. It offers improved surface finishes, reduced tool wear, and shorter machining times, making it the preferred choice for projects that demand both strength and accuracy.

Because of its superior machinability, 1045F steel is commonly used in industries where parts require intricate features, fine surface finishes, and high precision. Some of the most common applications include:

Automotive Components: Gears, shafts, and other critical parts used in automotive systems that require precise machining.

Machinery Parts: Components for industrial machines, including bearings, pulleys, and brackets.

Aerospace Components: Precision-engineered parts that need to meet strict tolerances and safety standards.

Oil & Gas Equipment: Parts that need to withstand tough operating conditions and be produced with high accuracy.

We provide comprehensive 1045F steel machining services, ensuring that every part we produce meets your specifications. Our team of skilled machinists uses the latest CNC equipment and cutting-edge techniques to deliver high-quality parts quickly and efficiently. Whether you need custom shafts, gears, or complex components, we have the expertise and equipment to meet your needs.

We offer the following services:

CNC Machining: Precision machining of 1045F steel parts using the latest CNC technology for tight tolerances and high-quality finishes.

Custom Part Fabrication: Tailored solutions for unique designs, ensuring that each component fits your specific application requirements.

Surface Finishing: We provide a range of surface finishing options, including polishing, grinding, and coating, to ensure that your parts meet aesthetic and functional standards.

Assembly and Prototyping: In addition to machining, we offer assembly services for custom parts and prototyping to test designs before full-scale production.

We specialize in the custom machining of 1045 carbon steel parts, providing tailored solutions for a wide range of industries. Our 50+ machinist expertise ensure that each part meets precise specifications, offering optimal performance for applications that require both durability and strength.

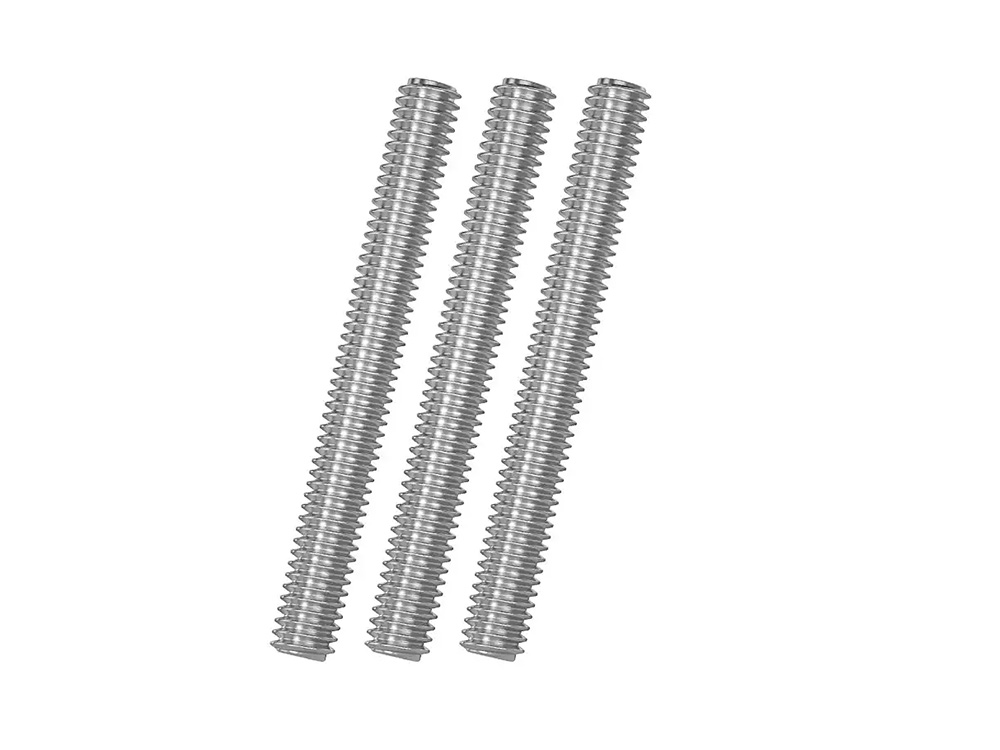

One of the most common applications for 1045 carbon steel is the machining of high-performance shafts. These components are vital in many machinery and automotive systems, requiring high precision and resistance to wear. We employ advanced machining techniques to deliver shafts that meet the highest industry standards, ensuring they perform reliably in demanding environments.

Its medium carbon content gives it a good balance between strength and ductility, but it can also increase the difficulty of achieving precise cuts and smooth finishes. Additionally, ensuring dimensional accuracy and consistency throughout a large production run requires skill and attention to detail. Our team is experienced in overcoming these challenges, using state-of-the-art equipment and techniques to meet your specifications.

For projects that require structural integrity, we offer custom welding services for 1045 carbon steel components. Whether it’s for machinery, equipment, or custom-built structures, our welding experts ensure that each joint is strong, durable, and free from defects. We understand the complexities of welding medium carbon steel, and we apply the appropriate techniques to maintain the material’s strength and integrity throughout the process.

With our expertise in custom machining and welding of 1045 carbon steel, we deliver parts that exceed expectations. Whether you’re looking for precision shafts, complex structural components, or custom solutions to meet specific needs, we are here to help you achieve your goals with high-quality, reliable parts.

We offer precise machining and surface finishing solutions for 1045 mild steel. Our team is dedicated to delivering high-quality, reliable components that meet your exact specifications. With our experience and state-of-the-art equipment, we ensure that your 1045 carbon steel parts are machined to the highest standards of performance and durability.

1045 carbon steel is known for its balance between strength and ductility, making it ideal for various machining applications. While it is more difficult to machine than low-carbon steels, it remains highly machinable with the right tools and techniques. We use advanced machinery and cutting-edge processes to ensure efficient machining, maintaining tight tolerances while minimizing wear on tools. This allows us to provide consistent, high-quality results for your projects.

Achieving a superior surface finish on 1045 carbon steel is critical for both aesthetics and function. A smooth surface can improve the part’s resistance to corrosion and wear, as well as enhance its overall performance. We prioritize precision in our surface finishing processes, whether it’s for fine-tuning the texture or achieving a mirror-like finish. We use specialized equipment and techniques, such as grinding, polishing, and coating, to ensure that every part meets stringent surface quality standards.

When it comes to custom machining 1045 carbon steel shafts, we understand the importance of precision. Shafts are critical components in machinery, requiring accurate dimensions and excellent mechanical properties. Our team is equipped with the expertise and tools needed to create shafts that perform reliably in demanding applications. Whether it’s a standard design or a customized solution, we can meet your specific requirements with high-quality, precision-engineered parts.

At [Your Company Name], we are committed to providing 1045 carbon steel parts with the highest levels of machining accuracy and surface finish quality. From shafts to complex components, we deliver solutions that stand the test of time and performance.

You can send us any questions to get any information you would like to know, and we will respond to you in extremely short time.