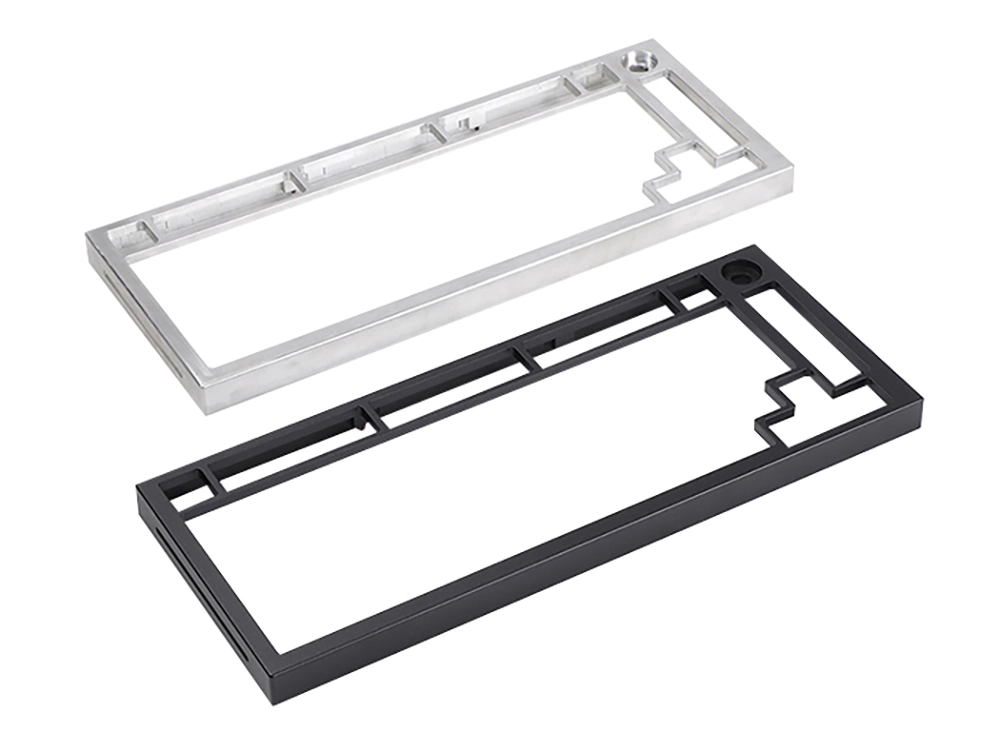

| Material | Aluminum alloy |

| Processing | CNC Milling |

| Surface finish | Anodizing |

| Application | Electronic products |

When it comes to CNC milling and anodizing aluminum keyboard cases, Chiheng has the setup, skills, and track record to deliver exactly what you need — whether it’s a one-off prototype or a full production run.

Producing a CNC aluminum keyboard case with an anodized finish is a multi-stage process. Each phase affects the final quality, so a tight workflow is key. Here’s how it typically goes:

For a premium aluminum keyboard case, tight tolerances matter. Most CNC aluminum keyboard manufacturers, including Chiheng, hold tolerances around ±0.02mm. This ensures:

QC steps like dimensional inspection, surface checks, and pre-anodizing cleaning are done to avoid defects later in the process.

If you’ve shopped for a premium mechanical keyboard, you’ve probably noticed many come in aluminum cases. There’s a good reason—aluminum offers the perfect balance of strength, precision, and style that serious users demand.

Aluminum stands out because it’s:

These factors make aluminum the go-to material for enthusiasts, custom builders, and professional keyboard manufacturers.

Aluminum keyboard enclosures come in several styles to suit different needs:

Many designs also feature detachable plates, internal weight blocks for stability, and anodized finishes for extra durability and style. In short, aluminum cases offer an unmatched blend of function, longevity, and aesthetics that plastic or acrylic simply can’t deliver.

For precision CNC machined aluminum keyboard cases, anodizing is more than just a cosmetic upgrade—it’s a key part of making the case both beautiful and long-lasting.

Chiheng also provide the following customization services of other surface treatment, processing and colors.

With anodizing, color is sealed into the aluminum’s surface, so it won’t chip or peel like paint. Common finishes include:

| Finish Type | Look | Popular Uses |

|---|---|---|

| Matte | Soft, non-reflective | Minimalist builds |

| Glossy | High shine | Premium/special editions |

| Textured/Satin | Subtle texture | Better grip, hides fingerprints |

| Dyed Colors | From standard black/silver to custom Pantone matches | Brand-specific or themed builds |

After anodizing, you can add fine details without damaging the coating:

Some designs blend anodizing with other treatments for extra style or protection:

For custom aluminum keyboard enclosures, anodizing offers flexibility without sacrificing quality. From classic black to vibrant custom hues, and simple engravings to complex mixed finishes, it’s an easy way to match your keyboard to your style or brand.

Chiheng runs a modern CNC machining shop in China equipped with:

This means they can handle the full process under one roof — milling, surface finishing, and quality checks — saving you time and reducing risk.

Chiheng has worked with U.S. mechanical keyboard brands on:

Every part goes through:

Clients often highlight that the first batch meets spec with no costly reworks.

Chiheng balances cost and turnaround so you can scale production without stress:

| Order Type | Typical Lead Time | Pricing Advantage |

|---|---|---|

| Prototype (1–5 pcs) | 7–10 days | Low tooling cost |

| Small batch (50–200) | 2–3 weeks | Volume discount |

| Bulk (500+ pcs) | 4–6 weeks | Best unit pricing |

You can send us any questions to get any information you would like to know, and we will respond to you in extremely short time.