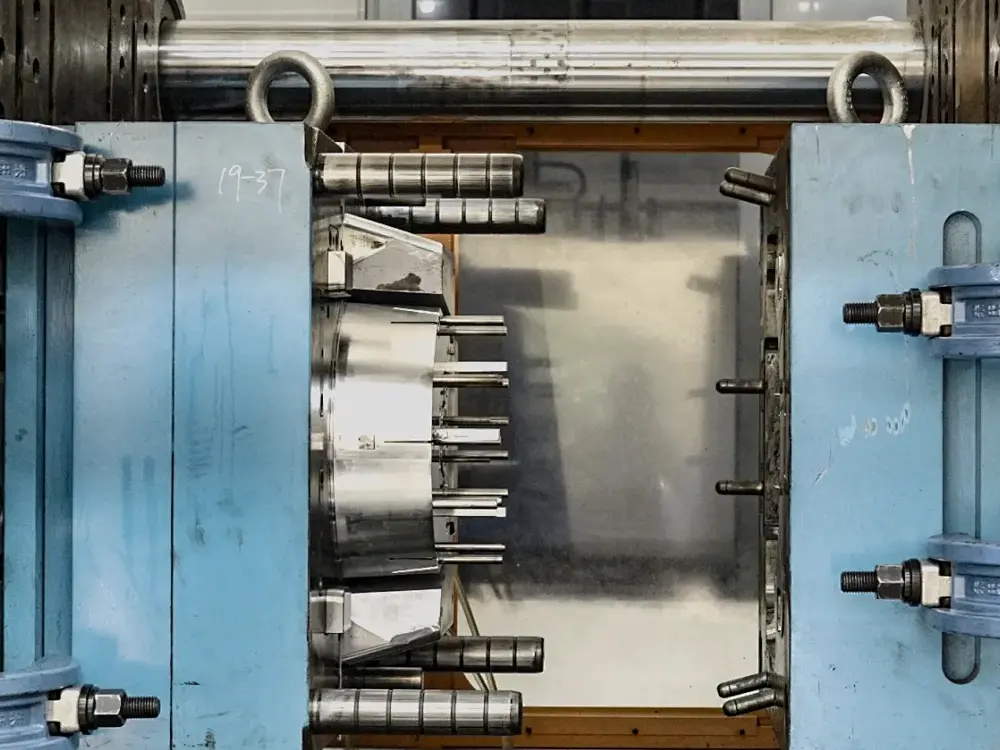

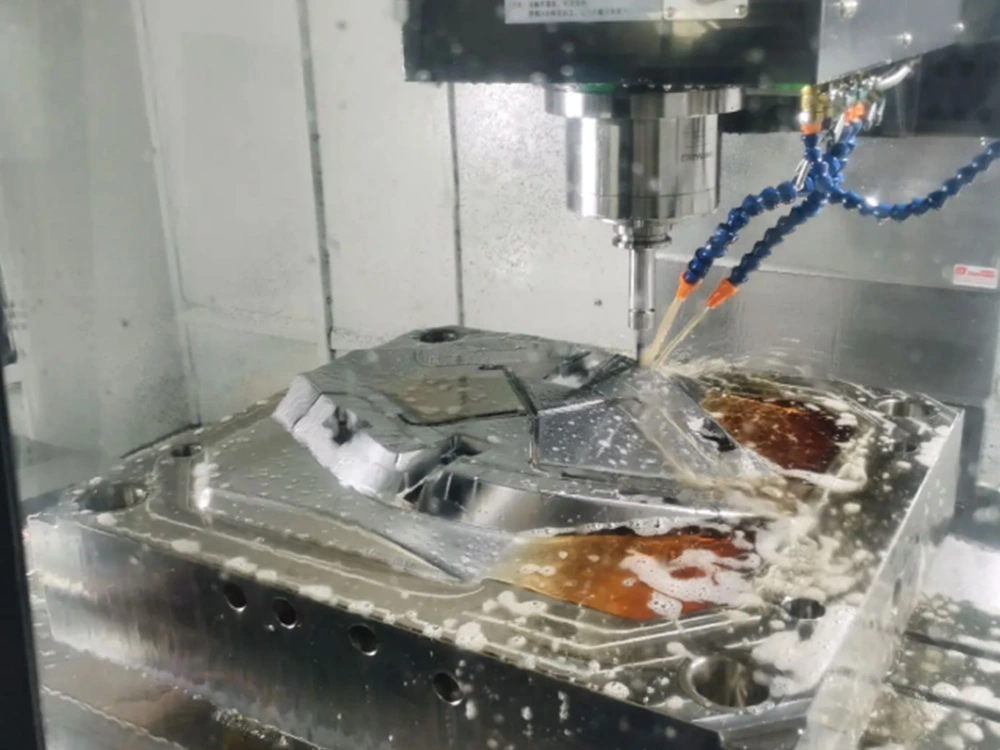

We invest in advanced injection molding equipment continuously.

Our technical capabilities position us to handle projects ranging from miniature precision components to large structural parts.

From initial concept to final delivery, we provide end-to-end injection molding services tailored to your specific requirements.

You save time with our complete molding solutions. You reduce costs with our streamlined process. One partner handles your entire injection molding project.

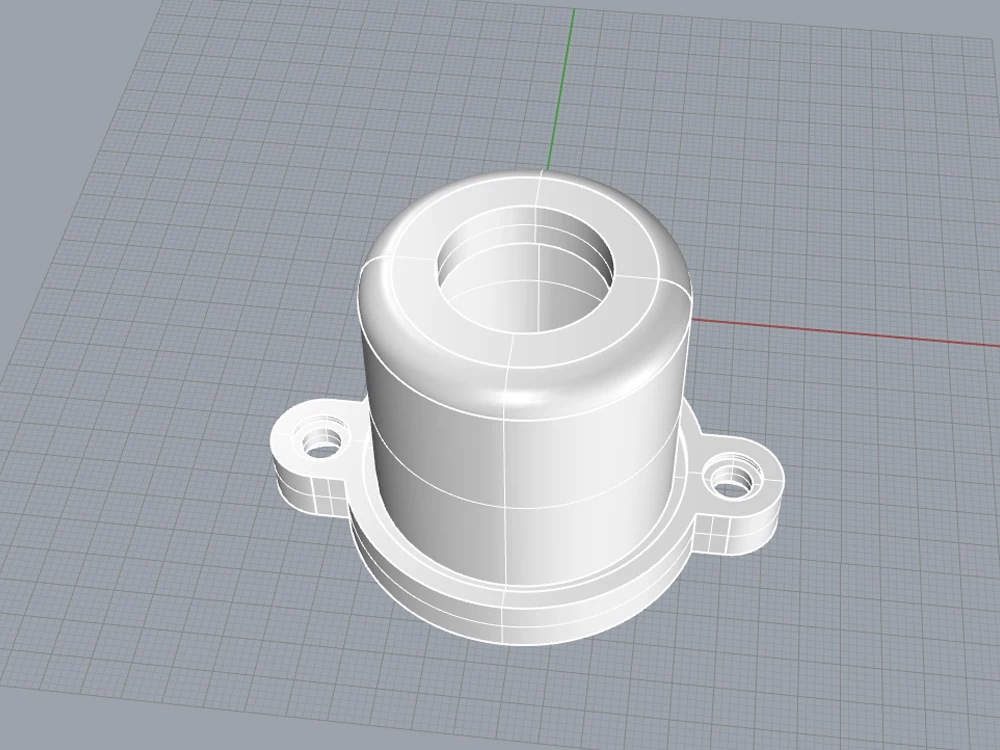

Expert engineering services including 3D modeling, and mold flow simulation to transform your concepts into optimized, manufacturable injection mold designs.

Rapid aluminum molds and bridge tooling delivered in 10-15 days for quick design validation and functional testing before committing to production.

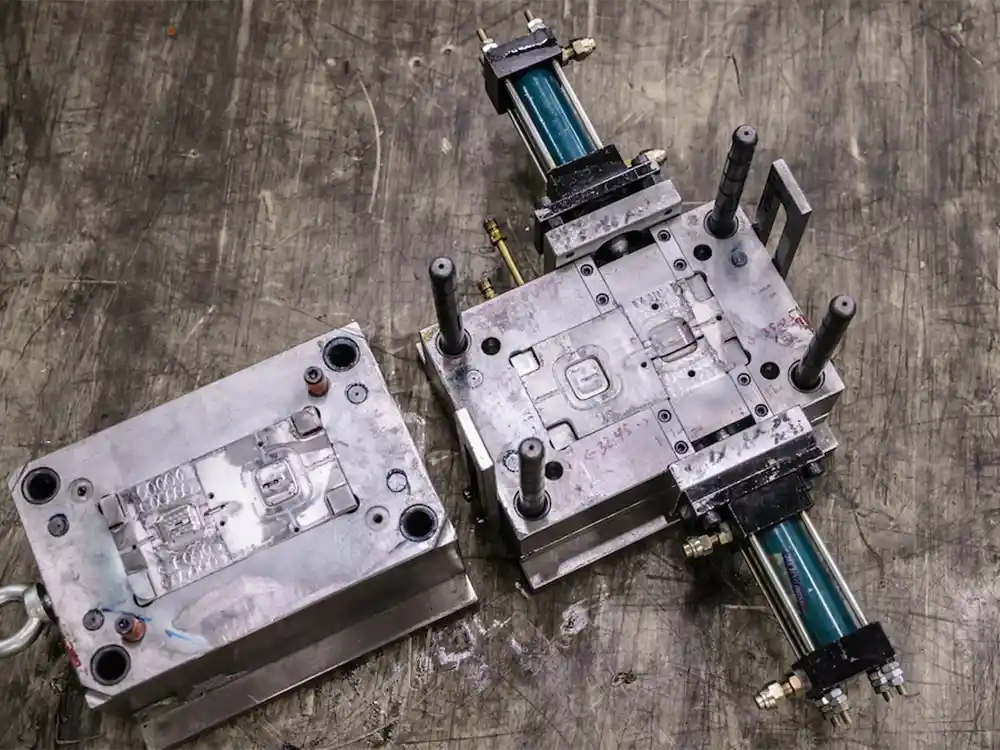

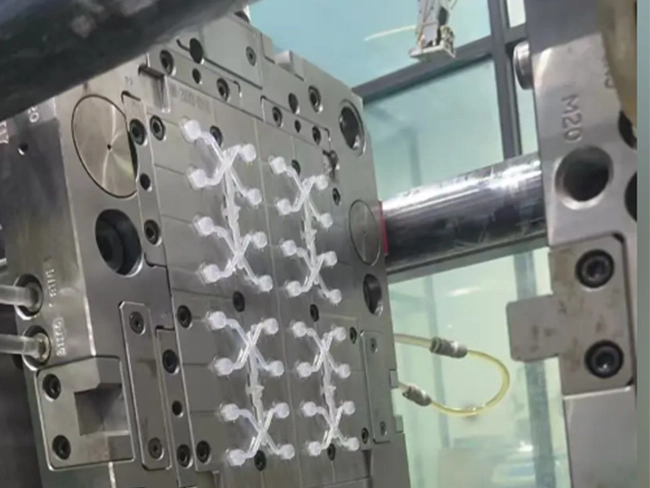

Precision steel molds (P20, H13, S136) engineered for millions of cycles with multi-cavity options, hot runners, and comprehensive documentation.

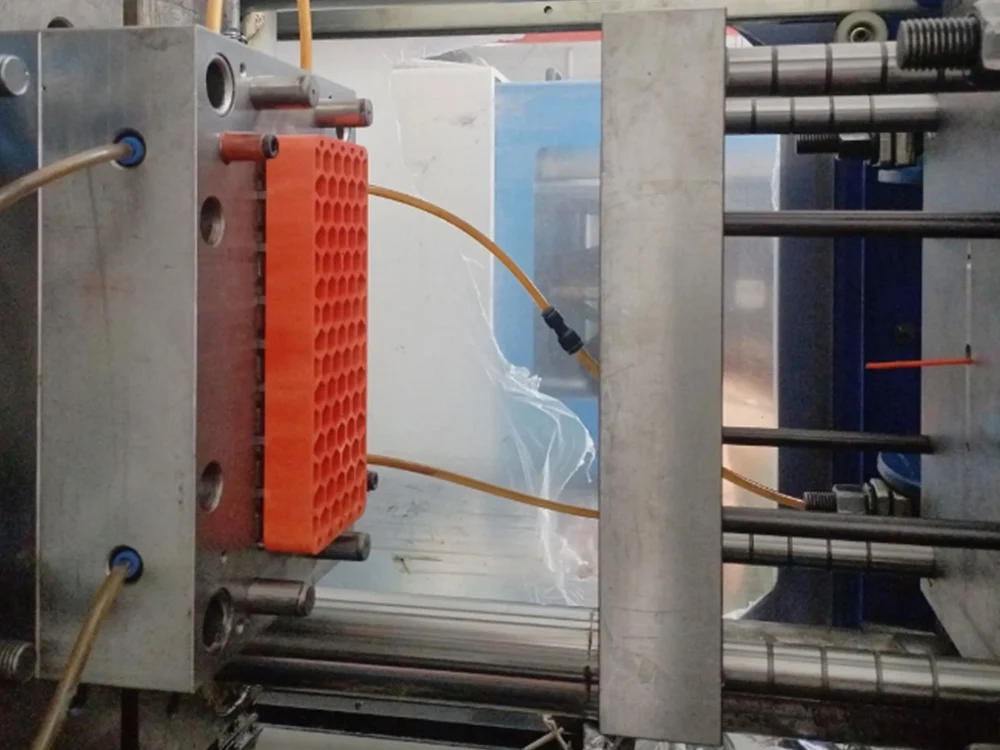

High-volume manufacturing with 50-2000 ton machines, real-time quality monitoring, and automated systems ensuring consistent results from 1,000 to 10 million parts.

Complete in-house finishing services including welding, printing, plating, painting, laser etching, and assembly for faster turnaround and simplified project management.

Specialized multi-material and metal-insert molding for enhanced functionality, soft-touch surfaces, and integrated assemblies that reduce costs and assembly time.

Technical Capabilities Specifications Table

We invest continuously in advanced equipment and skilled personnel to deliver injection molding solutions that meet the most demanding specifications. Our technical capabilities position us to handle projects ranging from miniature precision components to large structural parts.

| Specification | Range/Options | Details |

|---|---|---|

| Part Size Range | Minimum: 5mm × 5mmMaximum: 1500mm × 1000mm × 800mmOptimal: 50mm – 500mm | Micro molding capabilities availableBest cost efficiency in mid-size range |

| Dimensional Tolerance | Standard: ±0.05mm – ±0.10mmPrecision: ±0.01mm – ±0.03mm | Achievable with proper mold design and process controlCertified measurement using CMM and optical inspection |

| Wall Thickness | Minimum: 0.5mmMaximum: 6mmRecommended: 1.5mm – 3mm | Minimum for small, detailed featuresMaximum requires proper cooling designUniform thickness preferred to minimize warpage |

| Machine Tonnage | Small parts: 50T – 150TMedium parts: 200T – 500TLarge parts: 650T – 2000T | Precise tonnage selection ensures optimal part quality and cost efficiency |

| Mold Cavity Configuration | Single cavityMulti-cavity: Up to 128 cavitiesFamily moldsHot/Cold runner | Single cavity for large or complex partsMulti-cavity for high-volume small partsFamily molds for related components |

| Production Capacity | Annual: 50+ million partsDaily: Up to 200,000 parts24/7 operation available | Capacity depends on part complexityScalable to match business growthUrgent project support |

| Surface Finish Options | Standard: SPI A2, A3Textured: MT-11010 to MT-11070High gloss: Mirror finishMatte finish | Polished finish standardCustom textures availableOptical clarity or anti-glare options |

| Capability | Specification | Notes |

|---|---|---|

| Part Size | 5mm × 5mm (min) to 1500mm × 1000mm × 800mm (max) | Optimal: 50-500mm for cost efficiency |

| Tolerance | Standard ±0.05-0.10mm / Precision ±0.01-0.03mm | CMM & optical inspection certified |

| Wall Thickness | 0.5mm (min) / 6mm (max) / 1.5-3mm (recommended) | Uniform thickness minimizes warpage |

| Tonnage | 50T – 2000T (Small to Large parts) | Optimized selection for quality & cost |

| Cavities | 1 to 128 cavities + Family molds | Hot & cold runner systems |

| Capacity | 50M+ parts/year / 200K parts/day | 24/7 operation, scalable |

| Surface Finish | SPI A2/A3, MT-11010~11070, Mirror, Matte | Standard to custom textures |

Ready to start your next project? Upload your technical drawings, and our system will provide a quick, accurate quotation. Get professional guidance on material selection, lead times, and surface finishing options to ensure your part is both functional and cost-effective.

Chiheng Hardware serves industries from aerospace to consumer products. We offer tailored injection molding services. Our solutions meet the strictest global quality and regulatory standards.

Every project benefits from application-specific engineering. We deploy cutting-edge tooling technologies. Our manufacturing processes carry international certifications. We ensure reliability from prototype through full production.

Businesses demand quality-driven, flexible molding solutions. Forward-thinking companies choose Chiheng Hardware. We deliver precision-crafted components. We provide complete technical confidence.

All industrial you can get from our Tooling making or injection molding service, we are the best choice for you!

What are the commonly used injection molding materials?

Common injection molding materials include commodity plastics like PP, PE, ABS, and PS for general applications. Engineering plastics such as PA (Nylon), POM, PC, and PBT offer higher performance. High-performance options include PEEK, PPS, and PEI. Flexible materials like TPE, TPU, and Silicone are used for soft-touch applications.

What are the tools used in moulding?

Injection mold manufacturing requires CNC machining centers for precision cutting, EDM (Electrical Discharge Machining) for complex cavities, wire cutting machines for intricate details, surface grinders for finishing, and drilling machines. Quality control tools include CMM (Coordinate Measuring Machines), calipers, micrometers, and optical inspection systems.

What are the seven basic components of injection molding?

The seven basic components are the mold base providing structural support, cavity and core forming the part shape, runner system delivering molten plastic, gate controlling material entry, cooling system regulating temperature, ejection system removing finished parts, and venting channels allowing air escape during injection.

What are ejector pins and their features?

Ejector pins are cylindrical rods that push molded parts out of the mold cavity after cooling. Key features include hardened steel construction for durability, precise diameter tolerances for smooth operation, various head styles for different applications, and heat-treated surfaces to resist wear. They must withstand repeated cycles without bending or breaking.

What is the typical tolerances for injection molded parts?

Standard injection molding tolerances range from ±0.05mm to ±0.10mm for most commercial applications. Precision molding can achieve tighter tolerances of ±0.01mm to ±0.03mm with proper mold design, quality materials, and controlled processing conditions. Tolerances depend on part size, material shrinkage, and geometric complexity.

Here are the industries for the parts you can see in different realm.

You can send us any questions to get any information you would like to know, and we will respond to you in extremely short time.