Go beyond basic finishes with our comprehensive surface treatment services. Whether you need corrosion protection, aesthetic enhancement, or functional improvements, we have the expertise and technology to deliver exceptional results. Batch and low-volume production to accommodate various project sizes.

Why we are the most suitable supplier for your metal parts? See how we can provide to you with our best technoloty.

Established in 2015, Chiheng Hardware Co., Ltd. is a Chinese manufacturer with 15+ years of experience in high-precision CNC machining for metal and plastic parts. They offer comprehensive, one-stop solutions from prototyping to production.

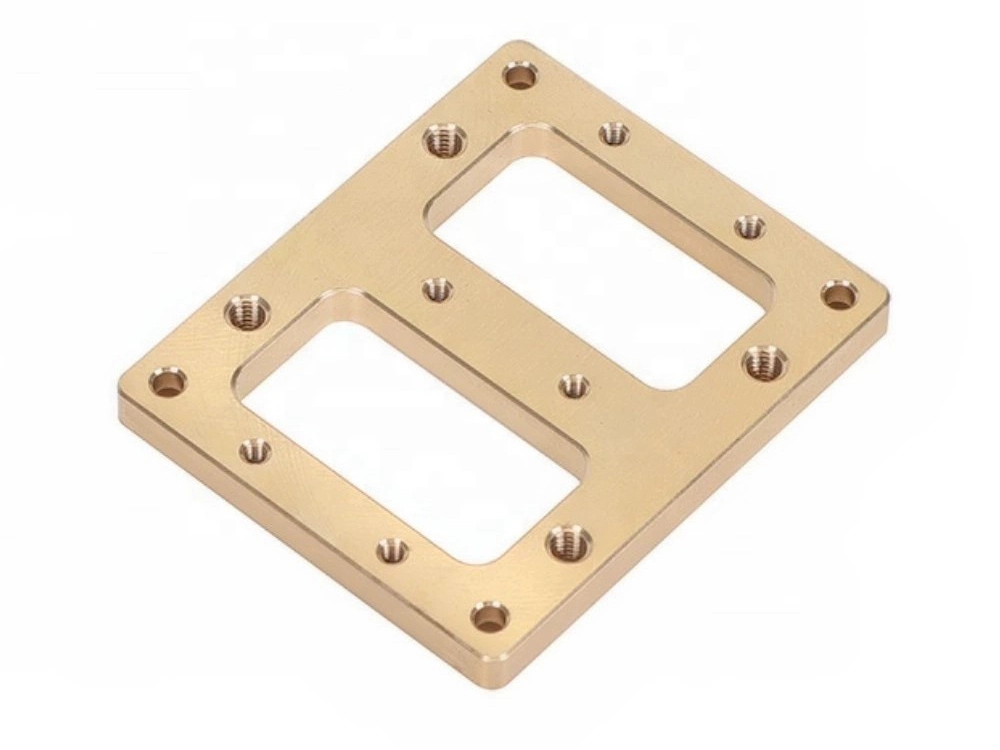

Metal and plastic surface treatments enhance a product’s aesthetics, feel, and durability. These finishes and coatings protect against environmental factors and improve properties like corrosion and UV resistance. Have a look at our samples.

To improve the corrosion resistance of metal parts, consider using electroplating or hot-dip galvanizing. Electroplating involves applying a thin metallic coating using an electrical current, which can protect against corrosion and enhance appearance.

Common metals used include zinc and nickel, which are particularly effective for corrosion resistance. Hot-dip galvanizing, on the other hand, involves dipping steel into molten zinc, forming a protective layer that is ideal for extreme environments, such as outdoor structures and guard rails.

For aluminum parts requiring enhanced wear resistance, anodic oxidation is a suitable choice. This process forms a hard, ceramic-like coating through electrolysis, which not only prevents corrosion but also significantly increases wear resistance.

Anodization can also be customized with dyes for aesthetic purposes. If additional hardness is needed, a thicker coating version can be specified to further protect the component from wear and tear

To enhance electrical conductivity, electroplating with metals like copper or silver is highly effective.

This process deposits a conductive layer onto the metal part, improving its electrical properties without altering its structural integrity. This treatment is particularly useful in electronics and telecommunications industries where high conductivity is crucial.

For components exposed to high temperatures, thermal spraying is an ideal solution. This process involves applying melted or heated materials onto the surface to create a protective barrier against heat.

It is commonly used as a thermal barrier coating in applications like exhaust systems and turbines to manage heat effectively and prolong component life.

You can send us any questions to get any information you would like to know, and we will respond to you in extremely short time.