Description

Swiss turning components represent the pinnacle of precision manufacturing, symbolizing the highest level of craftsmanship and pursuit of perfect quality. With their outstanding precision and excellent surface finish, Swiss turning parts hold a crucial position across various industries, including medical devices, aerospace, telecommunications, automotive, optical instruments, watchmaking, and precision machinery. These industries demand extremely high standards of precision, durability, and reliability, and Swiss turning technology meets and often exceeds these high standards with its unparalleled processing capabilities.

The core of Swiss turning technology lies in its unique processing method: during machining, the workpiece remains close to the tool due to the sophisticated design of a moving spindle and fixed tool. This design significantly reduces workpiece vibration and deviation while ensuring consistent high precision throughout the machining process. Compared to traditional turning techniques, Swiss turning is particularly suited for machining small, slender, and complex components, especially when high precision geometric shapes and minimal tolerances are required. Moreover, this technology effectively reduces material waste, making production more cost-effective and aligning with the sustainable development principles of modern manufacturing.

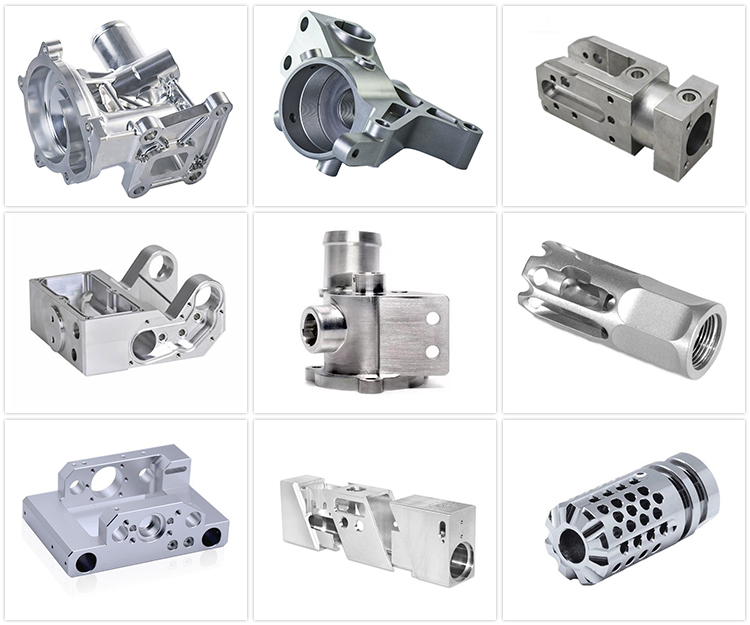

Chiheng Hardware Co., Ltd. specializes in producing various high-quality Swiss turning parts with Swiss turning technology at its core. The company possesses advanced CNC Swiss turning machines capable of precision machining in a highly automated environment, ensuring that each product meets strict quality standards. Our technical team has years of industry experience and extensive process knowledge, adept at handling complex machining requirements for different materials and shapes. Chiheng Hardware Co., Ltd. can process materials with diameters ranging from 0.5mm to 20mm, including stainless steel, brass, aluminum alloy, titanium alloy, and engineering plastics, covering a wide range from common to high-performance materials.

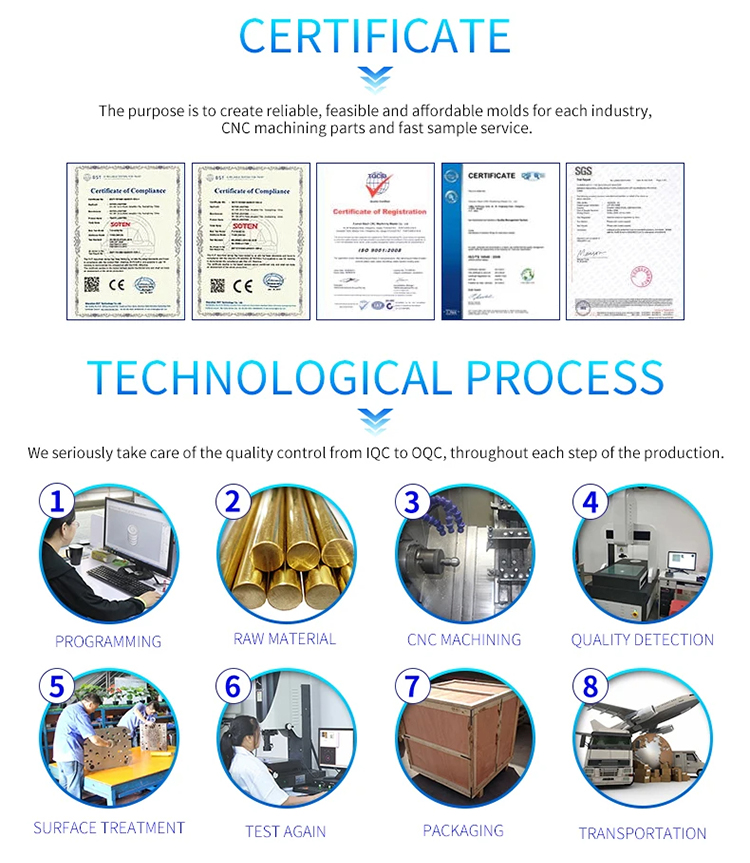

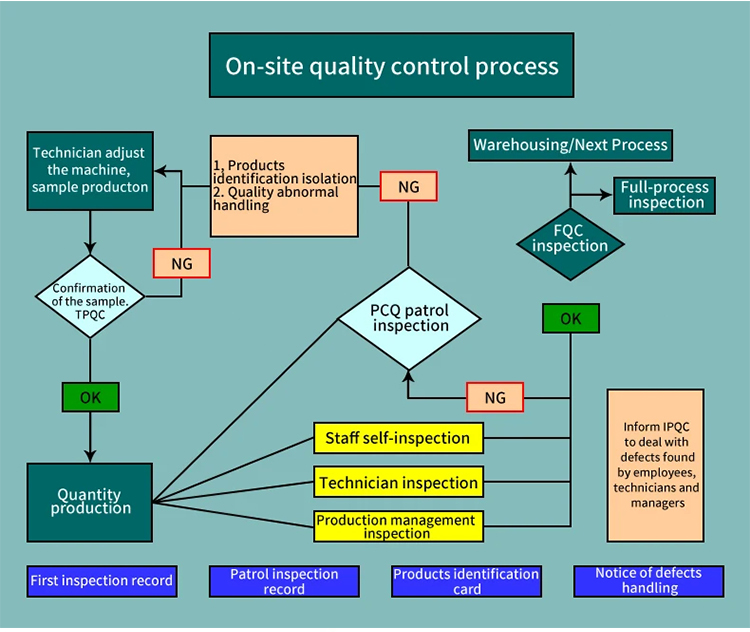

In our production process, we strictly adhere to international standards, committed to providing precision parts that fully meet our customers' specifications. Whether it's small-batch prototypes or large-scale production orders, Chiheng Hardware Co., Ltd. completes tasks with exceptional efficiency and accuracy. We understand that even minor errors can lead to serious consequences in many applications, so we enforce stringent quality control at every production stage to ensure that each Swiss turning part exhibits superior performance and reliability.

Additionally, our production process is highly flexible, allowing for customization according to specific customer requirements to ensure that the parts provided meet all specifications regarding size, shape, material, and functionality. Through precise Swiss turning technology, we not only meet current customer needs but also help them maintain a competitive edge in the market.

Chiheng Hardware Co., Ltd. adheres to the business philosophy of "Quality First, Customer Supreme," dedicated to providing high-quality Swiss turning parts and excellent service to global clients. We believe that with advanced craftsmanship and rigorous production management, we can add more value and reliability to your products. In future developments, Chiheng Hardware Co., Ltd. will continue to uphold this philosophy, innovate continuously, and refine our processes to offer the best precision component solutions to more industries.

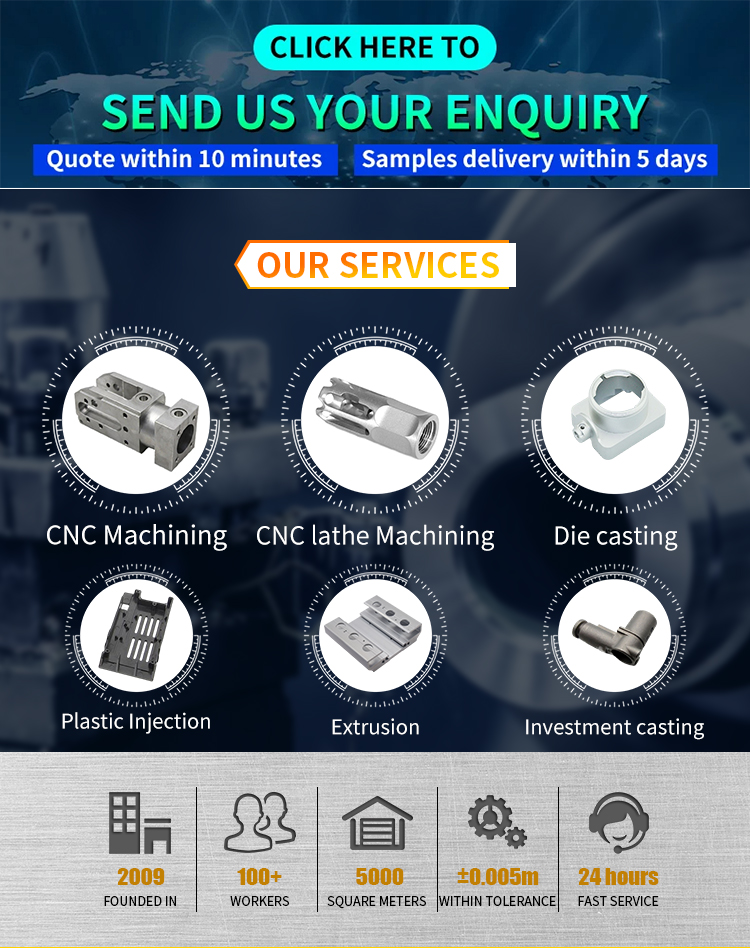

Dongguan Chiheng Hardwrare Co.,Ltd is a professional OEM metal fabrication factory which is located in Chang'an, Dongguan, China,and specialize in this field since 2009.

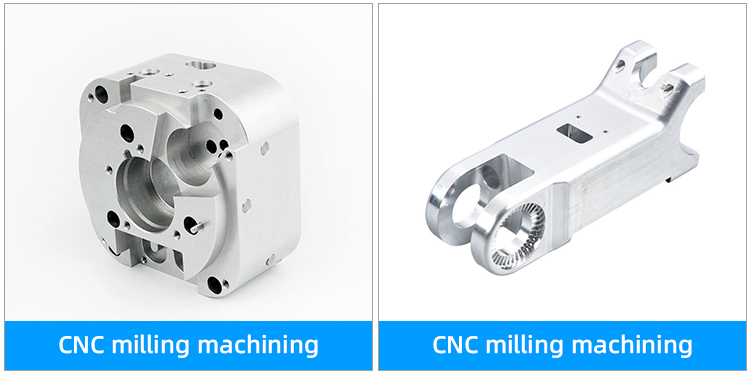

Our main business are CNC machining, plastic injection molding, die casting ,extrusion,Investment Casting and stamping parts.

We now have sophisticated CNC machining centers, engraving and drilling machine, Injection molding machine, stamping machine, compressor, lathe and milling machine, line cutting and other equipment.

With these machines and experienced employees, we are able to make repeated positioning accuracy within tolerance 0.005mm, providing strong guarantee for precision parts.

With great Service and nice quality,our products have been exported to USA, South America, Europe, Australia, Middle east and Southeast Asia, etc.Our goal is to make every customer happy.