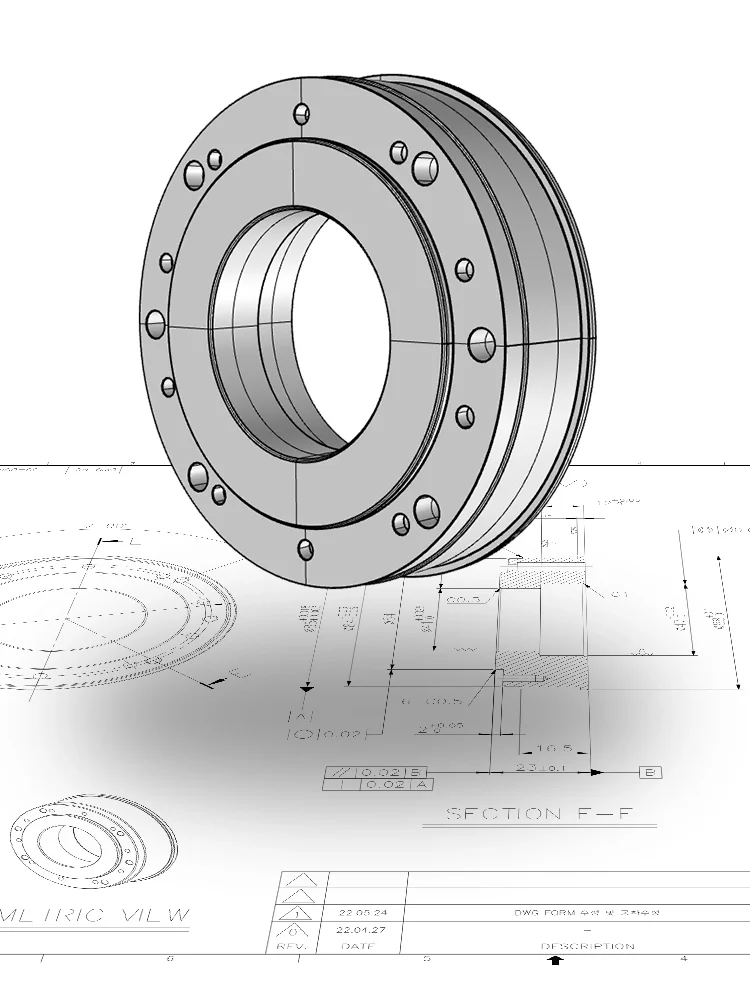

Looking for reliable precision parts manufacturer? We specialize in manufacturing precision components tailored to your drawings – no standard batches, just 100% bespoke solutions. From CNC milling and turning to laser cutting and grinding and more, our flexible processes handle leading metals, plastics, and composites. Our team ensures each part meets the highest precision standards.

www.chihenghardware.com has more than 17 years of professional multi-process machining experience. Our workshop integrates both CNC and manual machining techniques, allowing us to produce complex geometries, one-off prototypes, or small-batch parts with equal efficiency.

You already have — our team has delivered precision-machined components for clients across automotive, robotics, and industrial sectors worldwide.

Comprehensive capabilities — CNC + non-CNC hybrid processing.

Precision tolerance up to ±0.005 mm (0.0002”).

Fast turnaround for prototypes and small runs.

Material versatility — metals, plastics, composites.

Corrosion resistance expertise — stainless steel and protective finishes.

Secure data & IP protection — NDA and file encryption on request.

Our machining capabilities cover a wide range of materials:

Stainless Steel CNC Machining Service: Perfect for corrosion-resistant parts that demand strength and longevity.

Aluminium CNC Machining Service: Lightweight, high-precision, and cost-effective for prototypes or housings.

Engineering plastics (POM, ABS, Nylon, PTFE) for lightweight and low-friction components.

Aluminum | Brass | Copper | Stainless Steel | Alloy Steel | Steel Mild | Titanium | Low Carbon

ABS丨Acetal 丨CPVC丨 HDPE | LDPE丨 Nylon丨 PEEK丨 PEI | PET丨PMMA丨Polycarbonate | Polypropylene 丨 POM(Delrin) | PPSU 丨HIPS丨 PSU丨 PTFE丨 PVC

We offer a comprehensive suite of post-machining treatments to enhance durability, aesthetics, and functionality – all integrated seamlessly after CNC milling, turning, or laser cutting. Our corrosion-resistant coatings ensure parts withstand humidity, chemicals, and long-term wear — critical for aerospace, automotive, and medical industries.

Mechanical or electropolishing for mirror-like shines (Ra <0.8μm), boosting biocompatibility in medical devices.

High-pressure media abrasion for uniform matte textures (Ra 1.6-3.2μm), removing contaminants and enhancing coating adhesion by 25% – ideal for industrial enclosures and electronics housings.

Electrostatic application for thick, uniform layers (50-150μm) in custom colors, ideal for automotive parts needing impact protection.

(Type II/III): Builds a hard oxide layer on aluminum for corrosion resistance (up to 20% better in harsh environments) – perfect for aerospace components.

Chemical immersion in nitric acid for stainless steel, forming a passive chromium oxide film to boost corrosion resistance by 40% – essential for medical instruments and food processing components.

Electro-deposition of thin chrome layers (5-50μm) for hardness up to 800 HV, increasing wear resistance by 30% – suited for automotive fittings and heavy-duty industrial tools.

Upload your drawings, choose materials and finishes, and get an instant online CNC quote.

Our Online CNC Machining Service simplifies the process with:

Automatic manufacturability checks.

Transparent pricing.

Real-time progress updates.

Worldwide shipping options.

Whether you have a 2D CAD drawing, other file formats, or physical sample, we can bring your concept to life with precision machining.

Our engineers quickly interpret dimensional tolerances and surface requirements, converting your 2D designs into manufacturable 3D components.

From single prototypes to small-batch parts, our flexible setup ensures that even the most unconventional requests are handled smoothly.

We understand the importance of fast iteration and proof-of-concept validation.

Whether you need a single prototype or small-batch fabrication, our team ensures accuracy and consistency.

Rapid Prototyping Phase

Kick off with 1 piece. We deliver functional samples in 7 days.

The service for engineers who need:

Testing & Iteration

Validate your custom machined parts with in-house CMM inspections (±0.005mm tolerances) and material testing. Iterate quickly – tweak surface finishes like anodizing or bead blasting based on real-world feedback, ensuring 99% first-pass approval.

Scaling to Production

Seamlessly ramp up with our 40+ CNC mills and 45 lathes for consistent quality. From CNC turning cylindrical components (Ø2000x1000mm) to hybrid non-CNC grinding for ultra-smooth Ra 0.4μm finishes, we maintain precision across batches without setup delays.

Quality & Delivery Assurance

Full traceability via ISO 9001 protocols, global shipping (DHL partners), and on-time rates >95%. Track progress in our portal – get your precision parts from prototype to door in 15-30 days total.

Whether you’re innovating a prototype or scaling a low-volume run, our custom machining services transform your CAD drawings, sketches, or physical samples into precision-engineered components. Get your your bespoke projects with a robust fleet of 40+ CNC mills, 45 lathes, and high-power lasers, ensuring versatility for complex geometries and tight deadlines.

Model/Series | Description/Work Range | Quantity | Accuracy |

CNC Milling Machine V6 Series | Worktable: 800x500mm | 40 | ±0.005mm |

CNC Lathe CK46 | Spindle: Ø280x420mm | 45 | ±0.005mm |

CNC Lathe | Spindle: Ø2000x1000mm | 1 | ±0.005mm |

CNC Lathe | Spindle: Ø600x300mm | 1 | ±0.002mm |

Surface Grinder | Max Workpiece: 200mm | 1 | ±0.001mm |

Wire EDM | N/A | 2 | ±0.005mm |

Sinking EDM | N/A | 1 | ±0.005mm |

Model/Series | Description/Work Range | Power | Quantity | Accuracy |

Fiber Laser Cutting Machine | Worktable: 800x500mm (13 sets); 1500x3000mm | 800-500W | 40 | ±0.005μm |

Fiber Laser Cutting Machine | Worktable: 280x420mm (2 sets, 39° taper) | N/A | 45 | ±0.005μm |

Fiber Laser Cutting Machine | Worktable: 2000W model | N/A | 1 | ±0.005μm |

Surface Grinder | Worktable: 600x300mm | N/A | 1 | ±0.002μm |

Cylindrical Grinder | Max Workpiece: 200mm | N/A | 1 | ±0.001μm |

Wire EDM | N/A | N/A | 2 | ±0.005μm |

Sinking EDM | N/A | N/A | 1 | ±0.005μm |

Aerospace : Lightweight brackets, turbine components with tight tolerances.

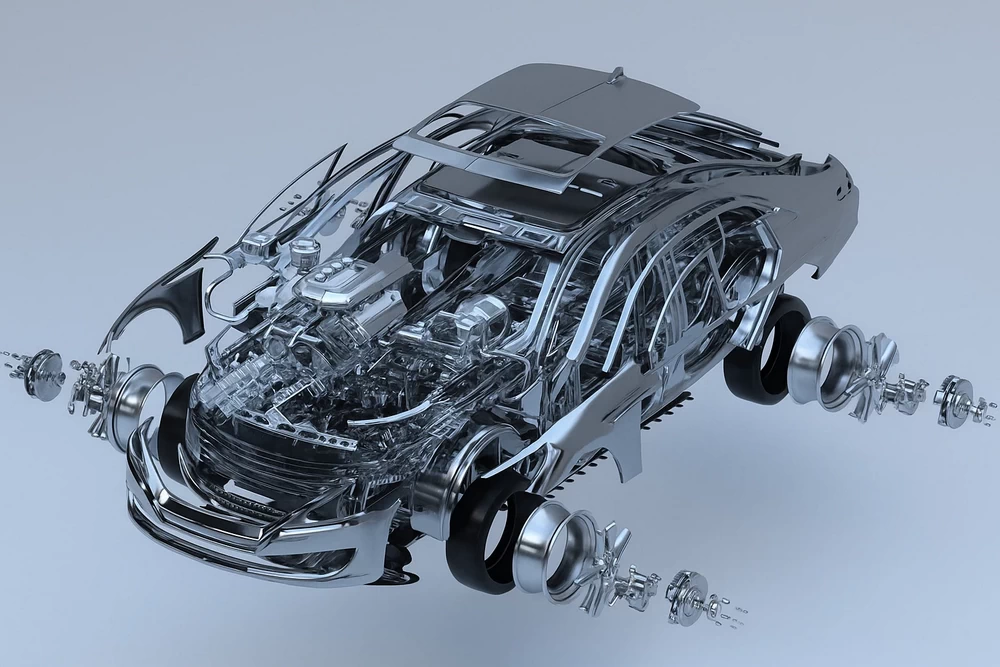

Automotive : Custom gears, engine prototypes for EV R&D.

Medical Devices : Implants, surgical tools in biocompatible materials.

Electronics : Housings, connectors for rugged tech.

Industrial Machinery : Wear parts, fixtures for heavy equipment.

With over 17 years of B2B experience, we’ve helped 500+ clients across global industries cut development time by 30% through our one-stop workflow: from initial consultation to final delivery.

Scale from one-off EV R&D parts to production with our batch scalability expertise, leveraging lean manufacturing to minimize waste. How expensive is milling? Costs depend on complexity, but our cost-effective outsourcing via 40+ CNC mills keeps it 20-30% below industry averages.

Our process is transparent, cost-effective, and backed by ISO 9001 certification – guaranteeing zero defects and on-time shipping.

1. Engineering for Custom Machining

2. Raw Material Ordering

3. Programming for Precision Machining

4. 1st Sample Approved

8. Final Product and Packaging

7. Chemical Resistance Finishing

6. Initial Sample Inspection

5. Prototyping and Production

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lead time depends on part complexity and quantity, but most prototypes are delivered within 3–7 business days after order confirmation.

Pricing for CNC cutting (like laser or milling-based) in our custom machining services is fully customized based on your unique needs – no fixed rates, just transparent breakdowns! Key stages influencing cost include:

Material & Thickness: Base cost varies by material type (e.g., aluminum vs. titanium) and thickness.

Complexity & Size: Simple 2D profiles charge less than intricate designs with tight tolerances (±0.005mm); larger worktables (up to 1500x3000mm) add setup time on V6 mills (800x500mm range).

Volume & Batch Size: Prototypes (1-10 pcs) have higher per-unit rates due to setup; scaling to 100+ pcs reduces costs by 40% through our 40+ CNC mills’ efficiency – no MOQ required.

Surface Finishes & Add-Ons: Basic delivery is standard; extras like anodizing or grinding (Ra 0.4μm) add 10-15% for enhanced durability, integrated post-machining.

Yes, our custom precision machined parts are manufactured in China, leveraging high-quality standards such as ISO 9001 certification. We specialize in CNC machining services for low-volume, high-precision parts used in industries like aerospace, automotive, and medical. China’s manufacturing capabilities allow for cost-effective, high-quality solutions with quick turnaround times, and we ensure our processes meet global standards.

A complimentary custom CNC machining service means end-to-end support — from technical drawing review and material selection to machining and finishing — ensuring you get a fully functional part without gaps in the process.

To ensure accurate quoting and manufacturing, please include:

Clear 2D drawings or 3D CAD files (STEP, IGES, STL, or SolidWorks).

Dimensions with tolerance callouts.

Surface finish and threading requirements.

Material type and heat treatment (if needed).

Quantity and delivery expectations.

If you’re unsure, our engineers can help optimize your drawing for machining efficiency before production begins.

We specialize in custom machining services for both metal and plastic materials, including:

CNC Milling – Ideal for detailed geometries, grooves, slots, and enclosures.

CNC Turning – Accurate cylindrical components and shafts.

Grinding & EDM – Tight tolerance surfaces and fine finishes.

Laser Cutting & Engraving – Fast, clean cuts for sheet metal parts.

Manual Machining & Finishing – For prototypes or unique, non-CNC features.

Here are the industries for the parts you can see in different realm.

Partner with us for your next custom machining project — precise, efficient, and fully customizable.

You can send us any questions to get any information you would like to know, and we will respond to you in extremely short time.