Description

Modern precision machining in the aerospace sector has become a cornerstone, leveraging advanced technologies like 5-axis CNC systems and lightweight materials to produce complex components with exceptional accuracy and efficiency. This computer-controlled process allows manufacturers to create complex components, from engine parts to structural elements, with accuracy measured in microns, ensuring the safety and reliability crucial for flight. From optimizing aerodynamic shapes and reducing production times to incorporating innovative materials like titanium alloys and carbon fiber composites, these solutions enable the creation of fuel-efficient, environmentally-friendly aircraft while meeting the industry's stringent safety and performance standards.

5 Axis Aerospace Machining Benefits

The implementation of Five-axis CNC machining benefits has revolutionized aerospace manufacturing, boosting the production of complex components. The implementation of Five-axis CNC machining benefits has revolutionized aerospace manufacturing, with CNC machining for turbine blades emerging as a prime example. This advanced technology enables simultaneous movement along five axes, creating intricate geometries like turbine blades with ultra-high precision and efficiency. The ability to reach all angles of complex components ensures perfect curves and edges, while reducing production time and achieving superior surface finishes crucial for aerodynamic performance. Key benefits include:

- • Enhanced precision and accuracy, crucial for producing aerodynamic shapes that improve flight efficiency

- • Reduced setup time and improved production speed, minimizing the need for workpiece repositioning

- • Ability to machine up to 5 faces in a single operation, increasing efficiency and reducing lead times

- • Superior surface finishes, essential for components requiring minimal friction and wear

- • Optimized tool geometry for maximizing metal removal rates, particularly beneficial for parts with high volume removal and poor machinability

These advantages contribute to the production of lightweight yet sturdy parts that meet the stringent requirements of machined parts to aerospace standards, ultimately leading to more fuel-efficient and environmentally-friendly aircraft.

Lightweight Metals in Aerospace CNC Machined Parts

Lightweight metals play a crucial role in aerospace CNC machined parts design, significantly contributing to weight reduction and improved fuel efficiency. Aluminum alloys remain a cornerstone material, comprising 70-80% of most civil aircraft structures due to their excellent strength-to-weight ratio and corrosion resistance. However, advanced materials are pushing the boundaries of light weighting:

- • Titanium alloys offer superior strength-to-weight ratios and high-temperature performance, making them ideal for engine components and landing gear.

- • Cutting parameters: Magnesium alloys, the lightest structural metals, are increasingly used in rotor hubs and engine parts, despite challenges with flammability.

- • Cooling: Scandium-aluminum alloys provide enhanced strength without compromising weight, enabling lighter airframes.

- • Carbon Fiber-Reinforced Polymers (CFRP) are revolutionizing airframe design, with the Boeing 787 Dreamliner's 20% weight reduction resulting in a 10-12% improvement in fuel economy.

These advancements in lightweight materials are critical for the aerospace industry, as removing just 1 kg of weight from an aircraft can save 106 kg of jet fuel annually, significantly reducing operational costs and environmental impact.

Titanium in aerospace machining acts lightweight yet incredibly strong. It's the go-to material for parts that need to be tough without weighing down the aircraft. Here's why titanium is so special in aerospace:

- • Strength-to-weight ratio: Titanium is as strong as steel but 45% lighter, making it perfect for parts that need to be sturdy without adding extra pounds.

- • Corrosion resistance: It laughs in the face of rust and harsh chemicals, like a suit of armor that never tarnishes.

- • Heat tolerance: Titanium can handle extreme temperatures, making it ideal for engine components that get super hot.

- • Versatility: CNC machining can shape titanium into complex parts with precision, from turbine blades to structural components.

This "lightweighting" trend is reshaping the aerospace industry, with innovations constantly pushing the boundaries of what's possible in aircraft design.

Advanced Aerospace CNC Machine Shop

Aerospace CNC machine shops have evolved to meet the demanding requirements of the industry, incorporating advanced technologies and processes to ensure the highest levels of precision and quality. These specialized facilities utilize sophisticated multi-axis CNC machines, often equipped with 5-axis capabilities, to manufacture complex aerospace components with tight tolerances and intricate geometries.

One of the key advancements in CNC machining aerospace is the implementation of Computer-Aided Manufacturing (CAM) software, such as MasterCam, which allows for seamless integration between design and production. This software enables engineers to optimize toolpaths, simulate machining processes, and identify potential issues before actual production begins, significantly reducing errors and improving efficiency.

Aerospace machining shops also employ advanced metrology equipment for quality control. Coordinate Measuring Machines (CMMs) and optical measurement systems are used to verify part dimensions with micron-level accuracy, ensuring compliance with stringent aerospace standards. These measurements are often integrated into statistical process control systems to maintain consistent quality across production runs.

Material expertise is another critical aspect of aerospace CNC machining services. Shops must be capable of working with a wide range of aerospace-grade materials, including high-strength aluminum alloys, titanium, Inconel, and other exotic alloys. This requires specialized tooling, cutting strategies, and coolant systems to effectively machine these challenging materials while maintaining tight tolerances and superior surface finishes.

Many aerospace CNC machine shops have obtained AS9100 certification, which is specific to the aerospace industry and builds upon ISO 9001 quality management standards. This certification ensures that the shop follows rigorous quality control processes and maintains traceability throughout the manufacturing process, which is crucial for aerospace applications where component failure can have catastrophic consequences.

To meet the industry's demand for rapid prototyping and iterative design, some aerospace CNC machine shops offer hybrid manufacturing capabilities. These combine traditional subtractive CNC machining with additive manufacturing technologies, allowing for the production of complex geometries that would be difficult or impossible to achieve through machining alone.

Aerospace CNC machine shops are also investing in automation and robotics to enhance productivity and consistency. Robotic tool changers, pallet systems, and in-process inspection systems are becoming increasingly common, enabling lights-out manufacturing and reducing human error.

As the aerospace industry continues to push the boundaries of performance and efficiency, CNC machine shops must constantly innovate to meet these evolving needs. This includes developing new machining strategies for advanced composite materials, implementing artificial intelligence for predictive maintenance and process optimization, and exploring new cutting tool technologies to improve machining efficiency and component quality.

Precision Turning for Cylindrical Components

Precision turning machining for cylindrical components is akin to a skilled engineer crafting a high-performance jet engine rotor, achieving remarkable accuracy. This process employs computer-controlled lathes to produce cylindrical parts with precision down to fractions of a millimeter. Here's what makes it exceptional:

- • It's ideal for manufacturing critical components like engine rotors, landing gear axles, and hydraulic actuators.

- • The machine rotates the material while a cutting tool meticulously shapes it, akin to a sculptor refining a masterpiece.

- • It can create both external and internal features, such as intricate grooves or polished surfaces.

- • Advanced techniques like 5-axis turning enable the creation of complex geometries, providing aerospace engineers with enhanced design capabilities.

This technology is vital in the aerospace industry, where CNC machining aerospace parts ensures every component meets stringent safety and performance standards.

Aerospace CNC Applications

With the rising demand for aerospace machining and components, the aviation sector continues to experience robust growth, showing promising signs of sustained expansion. To succeed in this competitive market, manufacturers must deliver machined parts to aerospace standards with consistent high precision. Here's how it's used:

- • Engine Components: CNC machines craft intricate engine parts like turbine blades and fuel nozzles, ensuring they can withstand extreme conditions.

- • Structural Parts: From wing skins to bulkheads, CNC creates strong yet lightweight components that form the aircraft's skeleton.

- • Ability to machine up to 5 faces in a single operation, increasing efficiency and reducing lead times

- • Superior surface finishes, essential for components requiring minimal friction and wear

- • Optimized tool geometry for maximizing metal removal rates, particularly beneficial for parts with high volume removal and poor machinability

These advantages contribute to the production of lightweight yet sturdy parts that meet the stringent requirements of machined parts to aerospace standards, ultimately leading to more fuel-efficient and environmentally-friendly aircraft.

| Component Type | Key Features | Material Selection | Manufacturing Challenges | Quality Requirements |

|---|---|---|---|---|

| Landing Gear Components |

• High load-bearing capacity • Shock absorption • Retraction mechanisms • Tolerances: ±0.0005" |

• Titanium alloys • High-strength steels |

• Complex geometries • Multi-part assembly • HIP joining required |

• Fatigue resistance • Impact resistance • Corrosion resistance |

| Wing Assist Plate |

• Aerodynamic profile • Load distribution • Structural integrity • Tolerances: ±0.001" |

• Aluminum alloys • Composite materials |

• Large surface areas • Thin wall sections • Surface finish critical |

• Stress distribution • Weight optimization • Aerodynamic efficiency |

| Emergency Hatch |

• Quick release mechanism • Safety interlocks • Seal integration • Tolerances: ±0.002" |

• Lightweight alloys • Composite materials |

• Precise fit requirements • Safety mechanism integration • Weather sealing |

• Reliability • Easy operation • Weather resistance |

Technical Resources

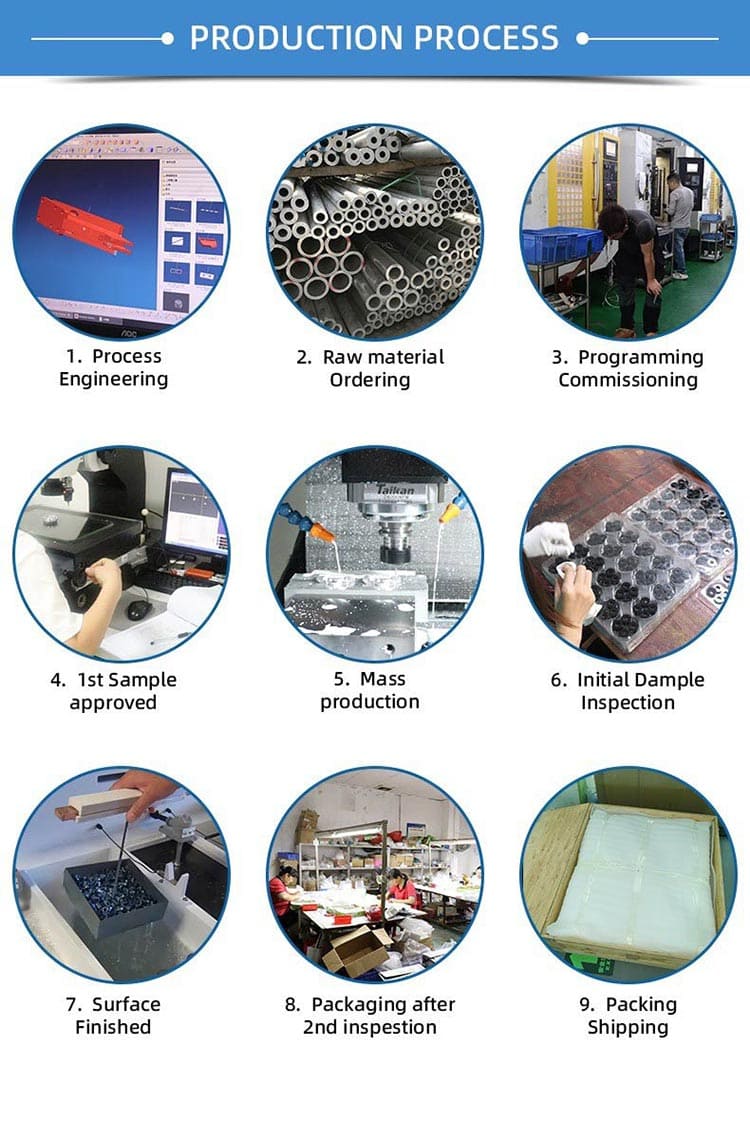

Manufacturing Process

FAQs (Machined Parts to Aerospace Standards)

Q: What is the importance of precision in aerospace manufacturing?

A: Precision is absolutely critical in the aerospace industry, as even the slightest deviation in part dimensions or material properties can have catastrophic consequences for aircraft and UAV performance and safety.

Q: What are the key advantages of aerospace CNC machining?

A: Aerospace CNC machining offers several key advantages, including the ability to work with a wide range of materials, the flexibility to handle a variety of manufacturing tasks, and the precision necessary to meet the most stringent aerospace specifications.

Q: What types of finishes are commonly used in the aerospace industry?

A: Aerospace parts often require specialized finishes, such as anodizing, plating, painting, and passivation, to enhance their durability, corrosion resistance, and visual appeal.

Q: What are the benefits of investing in aerospace precision machining?

A: The benefits of aerospace precision machining include increased efficiency, enhanced performance, improved safety, and long-term cost savings – all of which are essential in the highly competitive and safety-conscious aerospace industry.

Get instant quotes with free DFM feedback within minutes.

Contact Us

How to work with us?