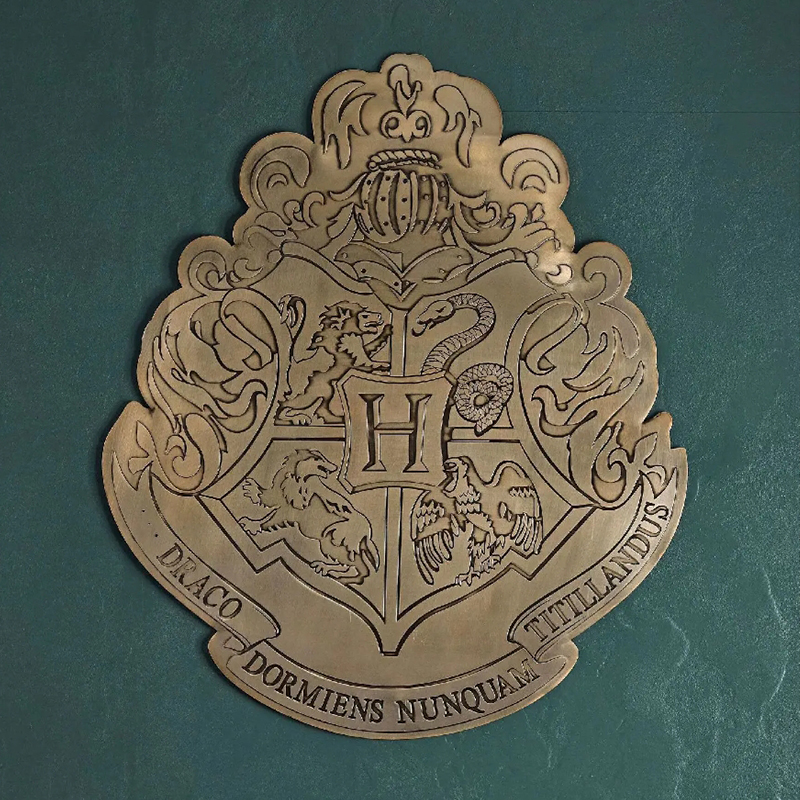

Diode laser relief engraving is a versatile technique used to create intricate 3D designs on a variety of materials. By carefully controlling the laser beam, you can achieve stunning depth and detail in your engravings. Here's a step-by-step guide to help you get started:

-

1.Material Preparation:

- • Choose a suitable material such as stainless steel, aluminum, or wood.

- • Ensure the material's surface is clean and free from contaminants.

-

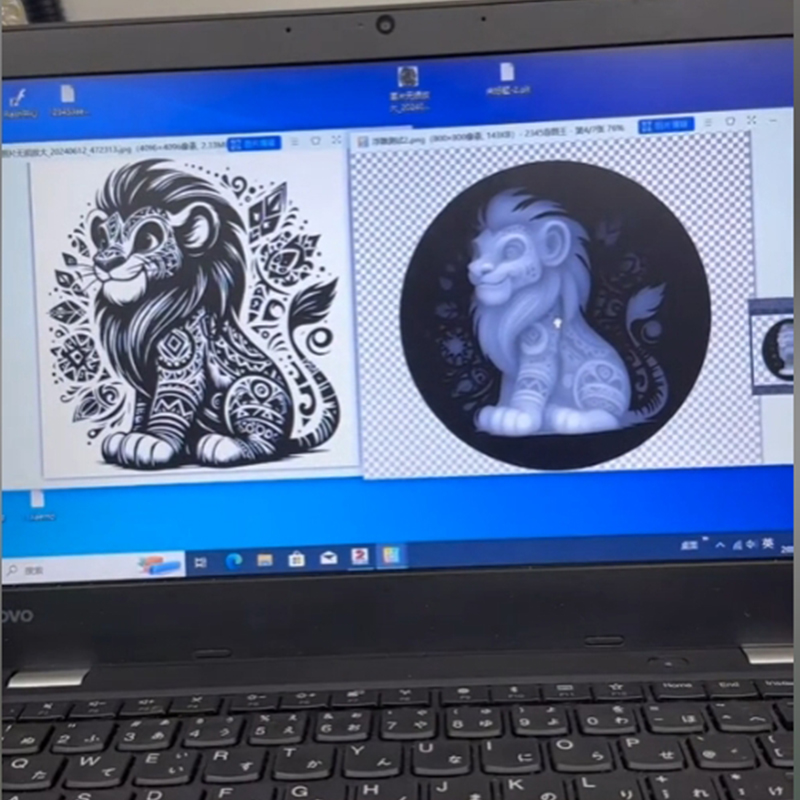

2.Design Creation:

- • Utilize design software (e.g., CAD, CorelDRAW) to craft your desired pattern.

- • Convert your image to grayscale and optimize contrast to enhance depth perception.

-

3.Laser Parameter Setup:

- • Configure the laser's power, speed, and frequency based on the material's properties and the complexity of your design.

- • Starting parameters: A higher power (30–100%) and lower speed (30–90%) typically provide deeper cuts.

-

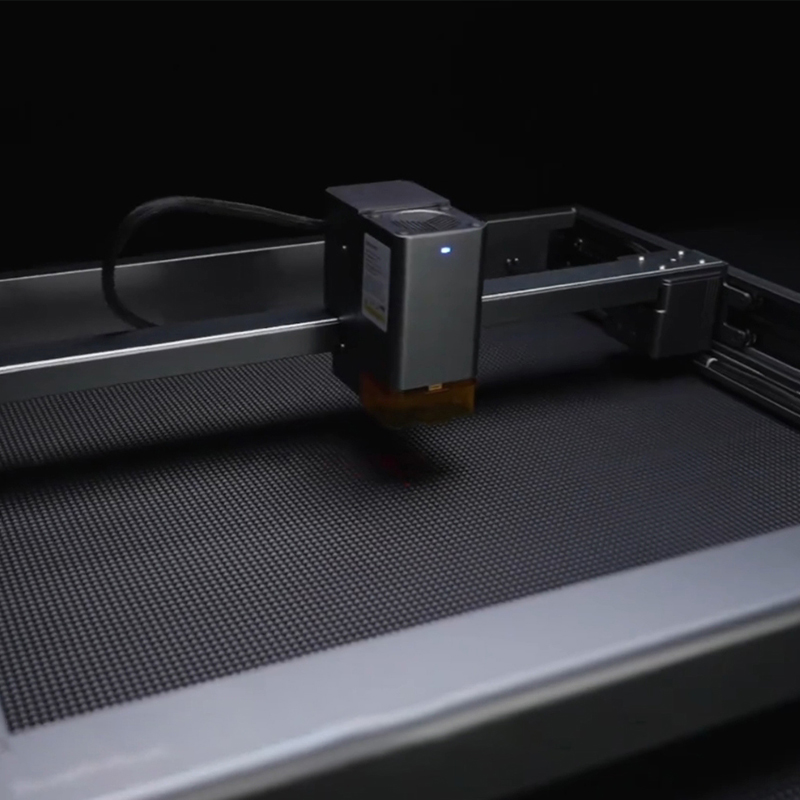

4.Workpiece Securing:

- • Firmly fasten the workpiece to the laser engraving machine's worktable.

-

5.Focusing:

- • Accurately focus the laser beam onto the workpiece surface to ensure optimal results.

-

6.Test Engraving:

- • Conduct a test engraving on a scrap piece of material to fine-tune power and speed settings.

-

7.Full Engraving:

- • Initial passes: Perform 3-4 passes at a lower speed and higher power to establish depth.

- • Finishing pass: Complete with 1-2 passes at a higher speed and lower power to remove any residual material.

-

8.Cooling:

- • Conduct a test engraving on a scrap piece of material to fine-tune power and speed settings.

-

9.Inspection and Refinement:

- • Carefully inspect the engraved piece and make adjustments to your parameters as needed to achieve the desired 3D effect.