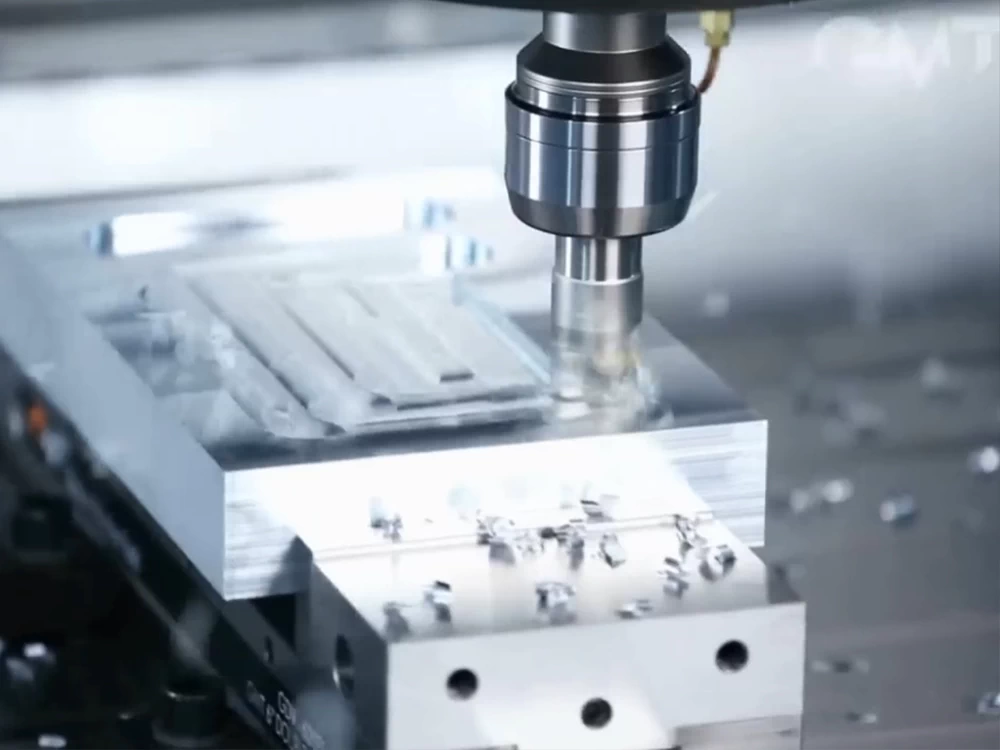

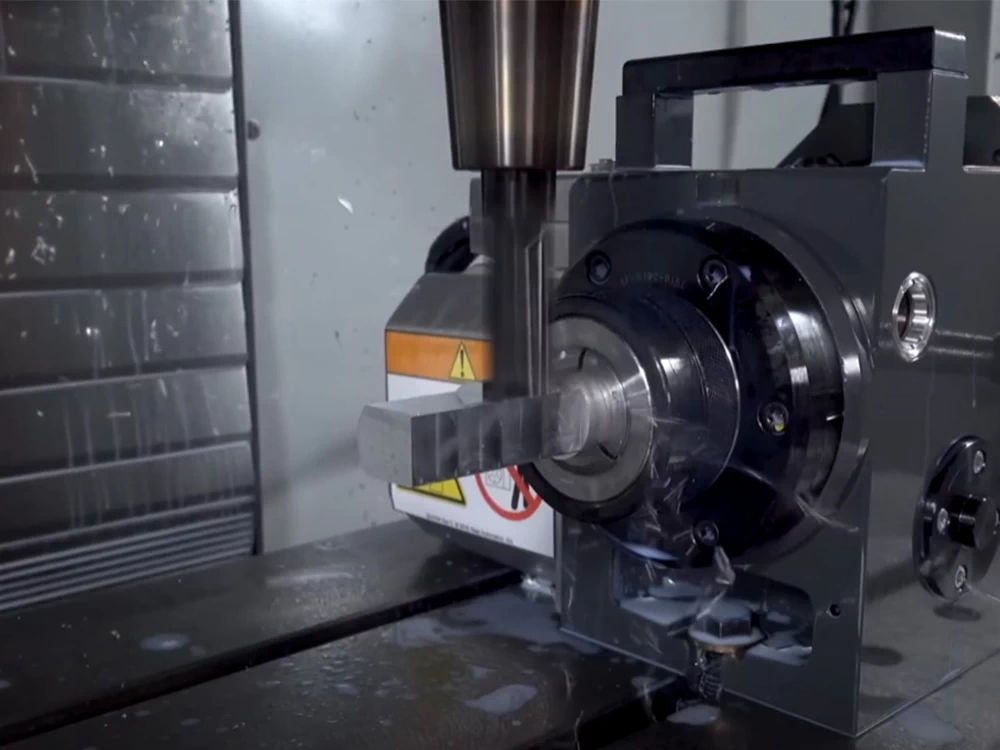

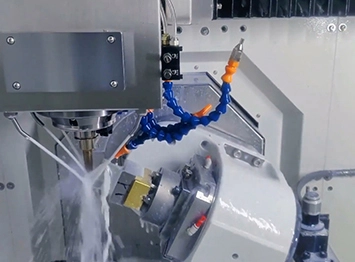

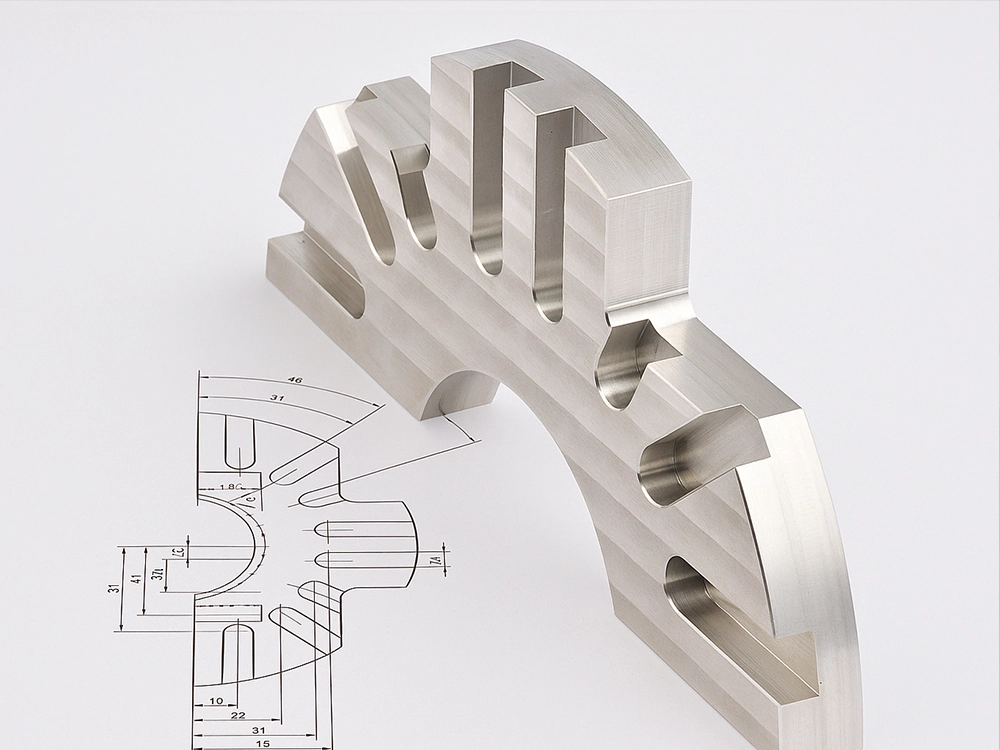

When precision, performance, and customization matter most, our custom CNC milling services deliver exact-fit solutions for your engineering needs. From one-off prototypes to small-batch production, we specialize in manufacturing non-standard parts using CNC milling, turning, grinding, and laser cutting. Whether you provide a technical drawing or a physical sample, our team transforms your concept into a finished part with uncompromising accuracy.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Our CNC machining solutions are designed for customers who need precision-engineered components rather than standard, mass-produced parts. We work with aluminum, stainless steel, brass, and engineering plastics, ensuring optimal surface roughness, corrosion resistance, and dimensional stability across every project.

Tailored for Non-Standard Parts: Perfect for prototypes, custom fixtures, and functional components.

Multiple Machining Methods: CNC milling, turning, grinding, wire cutting, and laser processing.

Fast Turnaround & Reliable Lead Times: Streamlined workflow to minimize production delays.

Tight Tolerances: Up to ±0.005mm for high-precision applications.

We offer single-side 3-axis machining, single-side 5-axis machining, with a minimum feature size and nominal thickness of 0.039 in (1 mm).

| Maximum Dimensions | Material | US | Metric |

| 3-axis** | ABS | 33.46 in. ×19.69 in. | 850mm × 500mm |

| POM | |||

| Nylon | |||

| pc | |||

| 3-axis** | Stainless steel | 33.46 in. ×19.69 in. | 850mm × 500mm |

| Titanium | |||

| Mild steel | |||

| Tool steel | |||

| 3-axis** | Aluminum | 33.46 in. ×19.69 in. | 850mm × 500mm |

| Cast iron | |||

| Copper | |||

| 5-axis | ABS | 10 in. x 7 in. | 254mm x 178mm |

| POM | |||

| 5-axis | Aluminum | 10 in. x 7 in. | 254mm x 178mm |

| Copper |

| Maximum Dimensions | US | Metric |

Size | 0.25 in. x 0.25 in. | 6.35mm x 6.35mm |

Nominal Thickness | 0.039 in. | 1mm |

*Hard metals: Ti 6Al-4V, stainless steels (303, 304, 316, 17-4PH), alloy steel (4140)

**Two-sided machining only.

We are capable of handling a wide range of materials and geometries:

Metals: Stainless steel, aluminum, brass, copper

Engineering Plastics: POM, Nylon, PTFE, ABS

High-Temperature Alloys: Ideal for aerospace and automotive components

Every manufacturing process is optimized for precision, from CAD modeling and CAM programming to final machining and finishing.

Aluminum | Brass | Copper | Stainless Steel | Alloy Steel | Steel Mild | Titanium | Low Carbon

ABS丨Acetal 丨CPVC丨 HDPE | LDPE丨 Nylon丨 PEEK丨 PEI | PET丨PMMA丨Polycarbonate | Polypropylene 丨 POM(Delrin) | PPSU 丨HIPS丨 PSU丨 PTFE丨 PVC

Ready to start your next project? Upload your technical drawings, and our system will provide a quick, accurate quotation. Get professional guidance on material selection, lead times, and surface finishing options to ensure your part is both functional and cost-effective.

High-quality surface finishing enhances both performance and aesthetics. Our comprehensive CNC surface finishing options include:

Polishing creates a smooth, mirror-like surface finish on CNC machined parts, enhancing both appearance and functionality. This process helps reduce surface roughness, improve reflectivity, and eliminate tool marks.

Bead blasting produces a uniform matte texture on metal and plastic CNC parts, improving both appearance and tactile feel. It effectively removes tool marks, burrs, and surface imperfections for a refined, satin-like finish.

A painted finish combines aesthetic flexibility with durable surface protection for custom CNC machined parts. It allows for specific colors, gloss levels, and branding requirements while shielding the part from oxidation and UV exposure.

Anodizing enhances the durability and corrosion resistance of aluminum CNC machined parts while adding a clean, professional appearance. The process increases surface hardness and provides excellent adhesion for paints or dyes.

Passivation is a chemical treatment that improves the corrosion resistance of stainless steel CNC parts by removing surface contaminants and forming a protective oxide layer. It’s a crucial step for components exposed to moisture, chemicals, or marine environments.

Nickel plating deposits a protective metal layer that enhances wear resistance, surface hardness, and corrosion protection for precision-machined components. It provides a shiny, smooth finish suitable for both functional and decorative applications.

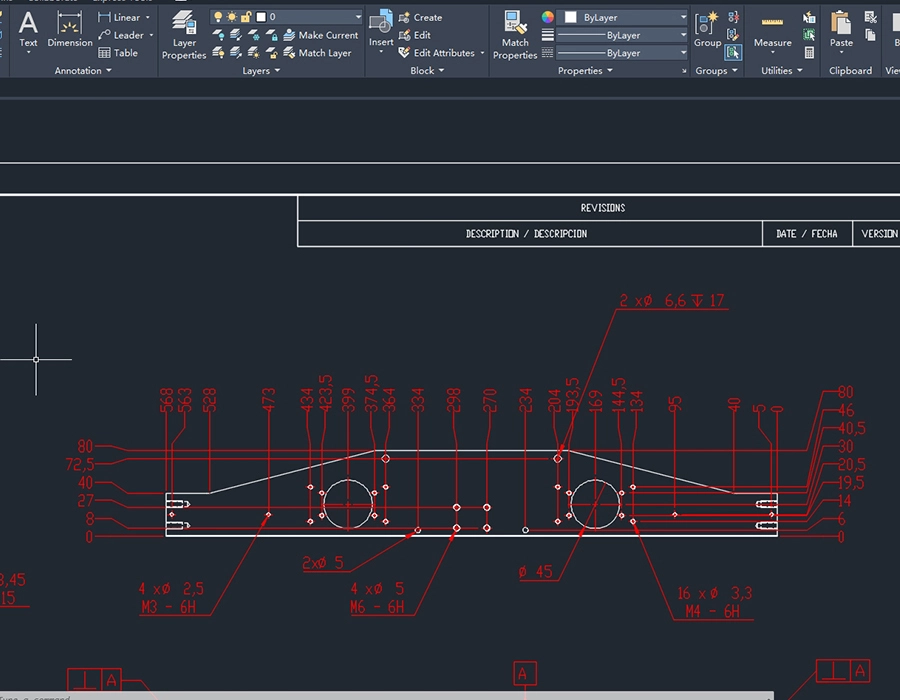

Simply send us your technical drawing or CAD file — we’ll review design feasibility, suggest machining improvements, and provide a detailed quotation. Our engineers assist with DFM (Design for Manufacturability) analysis to ensure optimal results before production.

We also support 2D CNC milling services and rapid prototyping for engineers testing form, fit, and function prior to mass production.

We have an entire manufacturing process for all product mass production, professional engineers team and the best CNC machining, thus we can control the quality and the lead time for your products for production

1. Mill Custom Process Engineering

2. Raw Material Ordering

3. Programming for milling

4. 1st Sample Inspection

8. Packaging After 2nd Inspection

7. Milling Parts Custom Surface Finish

6. Initial Sample Inspection

5. Mass Milling Production

All industrial you can get CNC parts from our service, we are the best choice for you!

What industries commonly require high precision machining?

Industries such as aerospace, medical device manufacturing, automotive, robotics, and electronics heavily rely on high-precision machining. These sectors require components with exacting tolerances and flawless reliability, which our custom CNC milling services consistently provide.

What factors determine the cost of a custom CNC part?

The primary cost drivers are machining time (based on design complexity), material cost, the number of parts in the production run (volume discounts often apply), and any secondary surface finishing or heat treatment processes required.

What is the typical lead time for CNC machined parts?

Standard lead times typically range from 5 to 15 business days, depending on the project’s scope. We also offer expedited services for urgent prototyping needs. The most accurate lead time will be provided with your official quote.

How do I prepare a technical drawing for CNC milling?

A good technical drawing should include clearly dimensioned 2D views, 3D model files (STEP or IGES are preferred), material specifications, required tolerances for critical features, and any notes on surface finish or other special requirements.

Here are the industries for the parts you can see in different realm.

You can send us any questions to get any information you would like to know, and we will respond to you in extremely short time.