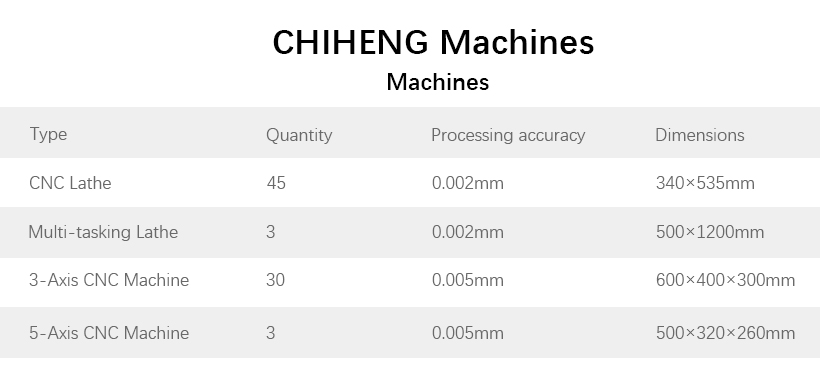

CNC Machining Equipment

Our CNC Equipment List

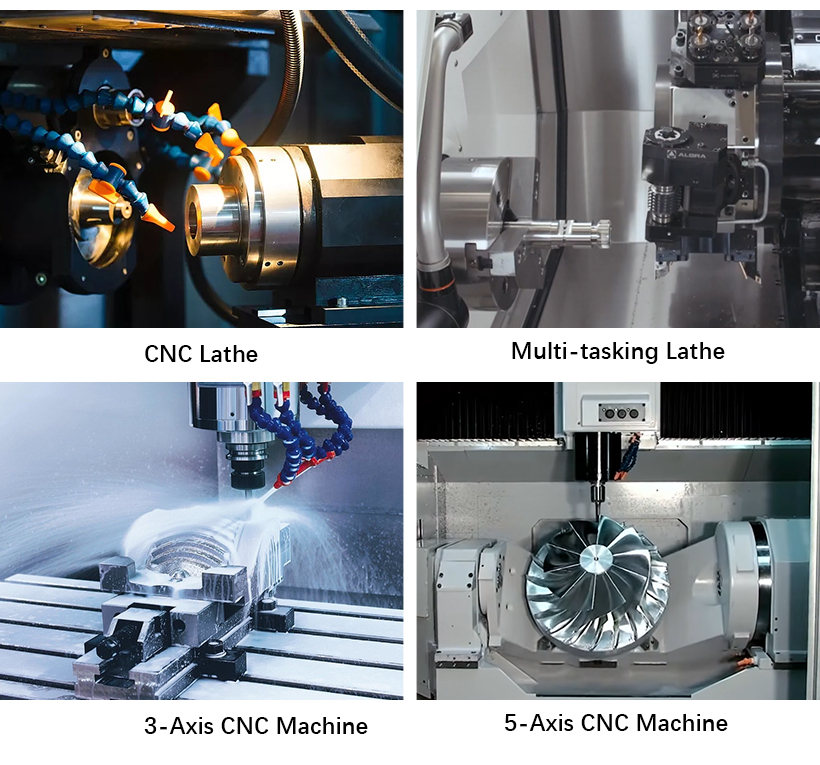

Our CNC Equipment Outlook

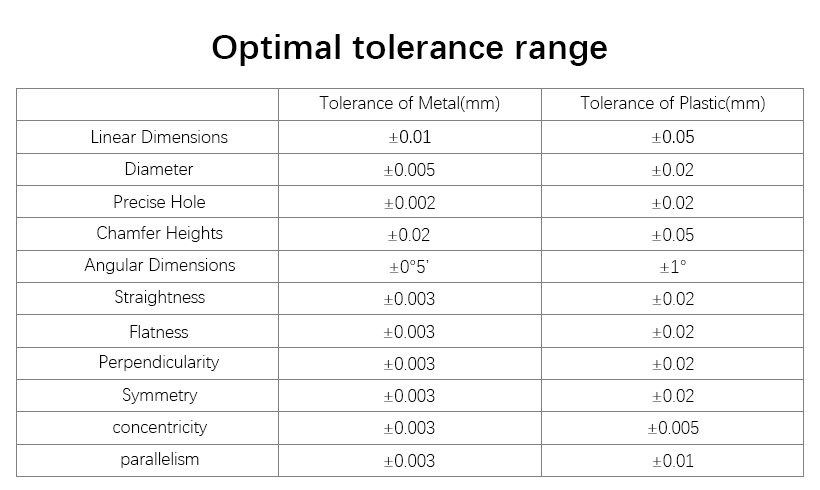

What can these machines achieve?

CNC machining is a highly precise manufacturing process used to create complex parts with intricate details. To ensure that these parts meet the required specifications, it's crucial to understand the concept of tolerance.

Tolerance refers to the acceptable variation in a part's dimensions. It defines the maximum and minimum allowable deviation from the nominal size. For example, if a part is supposed to be 10mm long, a tolerance of ±0.1mm would mean that the actual length could be anywhere between 9.9mm and 10.1mm. We offer ±0.005mm precision tolerance.

General Tolerance in CNC Machining

The general tolerance for a part depends on the specific requirements of the application. There are various standards and specifications, such as ISO, ANSI, and ASME, that provide guidelines for tolerance. These standards help ensure consistency and compatibility between parts from different manufacturers.

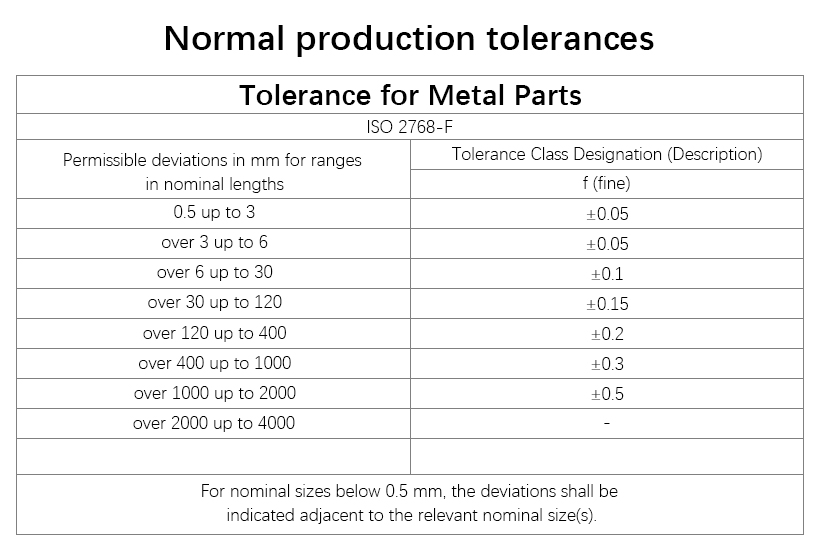

Tolerance for Metal Parts

Metal parts require strict tolerances to ensure their functionality and performance. Factors such as the material, part complexity, and intended use influence the tolerance level. For instance, a metal part used in a high-precision instrument might require a tighter tolerance than a part used in a less critical application.

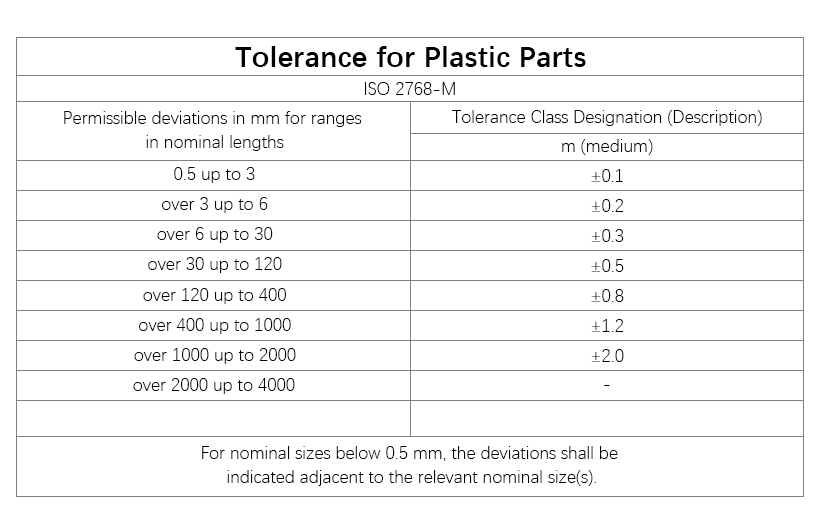

Tolerance for Plastic Parts

Plastic parts also have tolerance requirements, but they are generally less stringent compared to metal parts. Plastics have a higher degree of elasticity, which allows for some variation in dimensions without affecting their functionality. However, factors like the type of plastic, part thickness, and environmental conditions can influence the tolerance.