CNC Measuring Tools and Equipment

Our CNC measuring tools and equipment ensure the highest level of precision, making them ideal for applications demanding tight tolerances in industries like medical, automotive, and scientific.

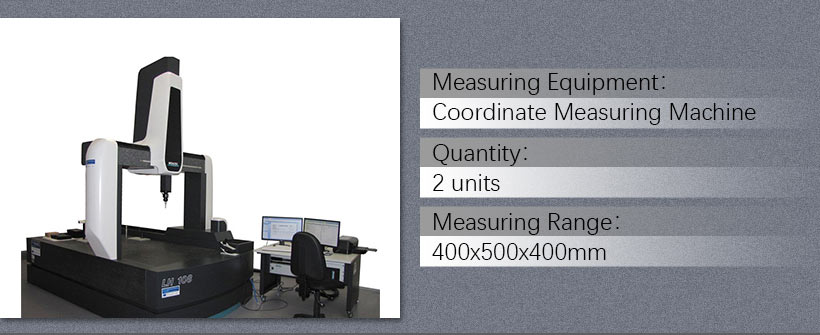

Coordinate Measuring Systems

|

Coordinate Measuring Machine (CMM) A precision measuring system that uses a probe to determine the coordinates of points on an object's surface, allowing for complex 3D measurements and quality control. |

Used for precise 3D measurements of complex parts. CMMs can measure geometric characteristics like dimensions, contours, and surface profiles with high accuracy. |

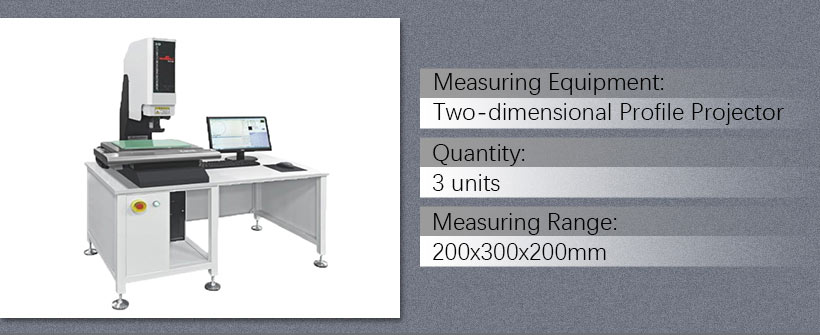

Optical Measurement Tools

|

Vision Measuring Machine(Optical Measuring Machine) An optical system that uses cameras and image processing to perform non-contact measurements, ideal for small or delicate parts. |

Performs non-contact measurements using cameras and image processing. Ideal for inspecting small, delicate, or flexible parts that cannot be touched. Widely used in electronics, medical device manufacturing, and micro-component industries. |

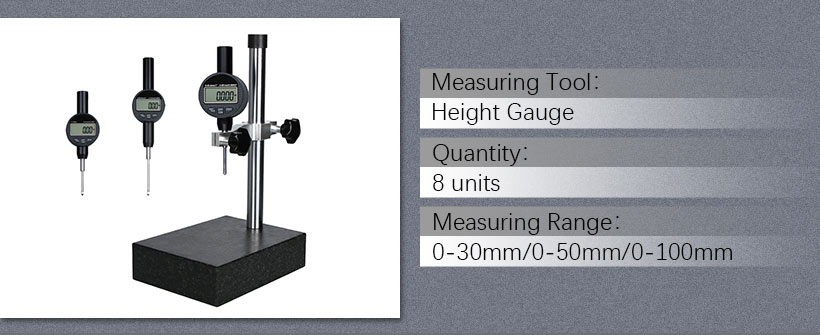

Dimensional Measurement Tools

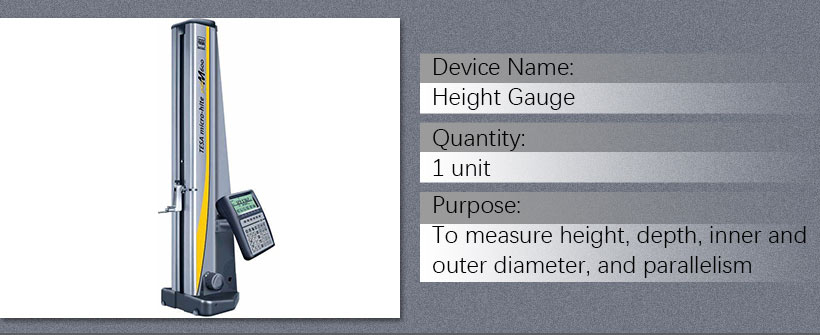

Height Measurement Tools

|

Height Gauge A precision instrument for measuring vertical distances, often used in conjunction with a surface plate for accurate height and scribing operations.A precision instrument for measuring vertical distances, often used in conjunction with a surface plate for accurate height measurements and scribing. |

A versatile tool for measuring vertical distances and scribing lines on workpieces. Used in machine shops for setup and inspection tasks. Digital models offer enhanced precision and data output capabilities. |

Linear Measurement Tools

|

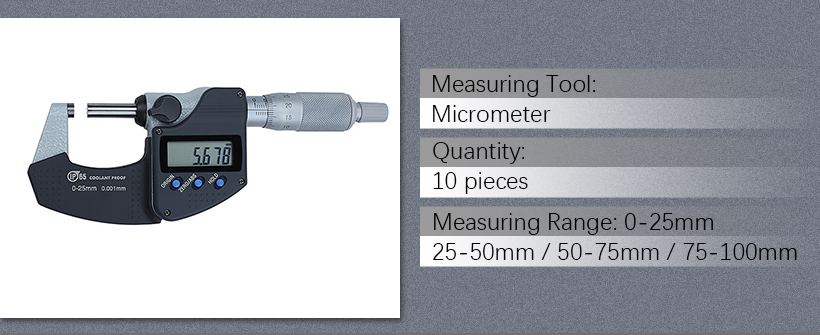

Micrometer A highly accurate measuring tool for determining the thickness, depth, or diameter of objects, typically capable of measurements to 0.001 mm. |

Provides highly accurate measurements of thickness, diameter, and depth. Essential for precision machining and quality control. Available in various types (digital, mechanical) and ranges to suit different applications. |

|

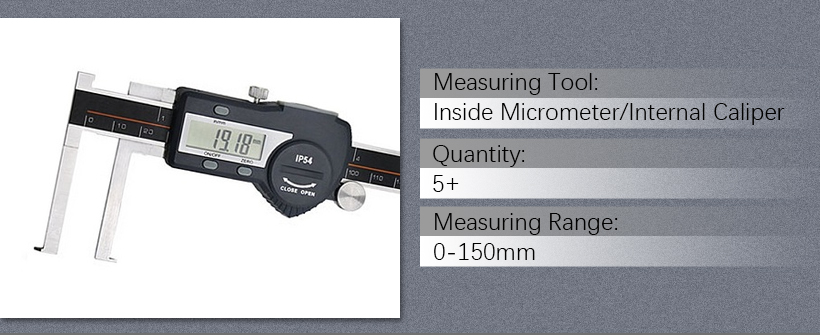

Inside Caliper A versatile measuring instrument that can measure internal and external dimensions, as well as depth, with typical accuracy to 0.02 mm. |

Specifically designed for measuring internal diameters and distances. Crucial for inspecting bores, cavities, and grooves in machined parts. |

|

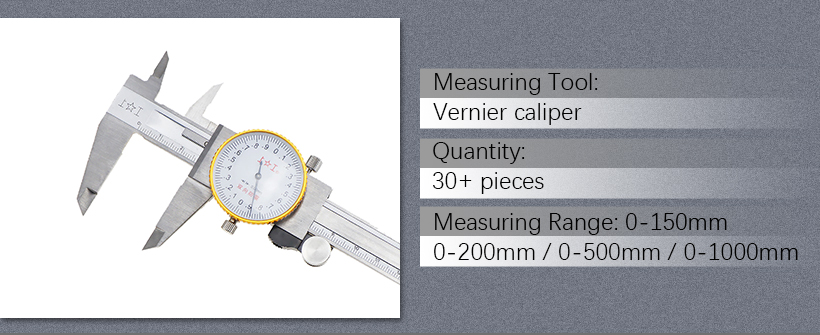

Vernier Caliper Similar to a vernier caliper but with a dial indicator for easier reading, offering quick and precise measurements. |

A versatile measuring tool for external and internal dimensions, as well as depth. Digital versions offer quick, precise readings. Indispensable in machine shops, quality control departments, and engineering labs. |

Thread Measurement Tools

|

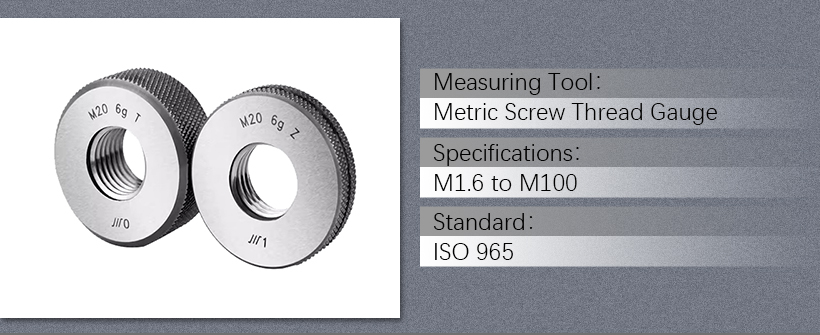

Metric Screw Thread Gauge A precision measuring tool used to verify the accuracy of Unified National Thread (UNC) or Unified National Fine Thread (UNF) profiles. |

It consists of a plug gauge (go gauge) and a ring gauge (no-go gauge). The plug gauge should thread easily into the workpiece, while the ring gauge should not.Commonly used in manufacturing industries to ensure that threaded parts meet specified tolerances. |

|

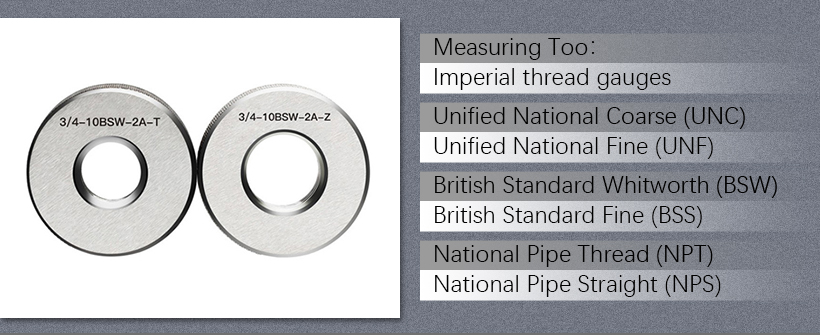

Unified and Whitworth Screw Thread Gauge A precision measuring tool used to verify the accuracy of British Standard Whitworth (BSW) or British Standard Fine (BSF) thread profiles. |

Similar to the Metric Screw Thread Gauge, it consists of a plug gauge and a ring gauge. The plug gauge should thread easily into the workpiece, while the ring gauge should not. |

|

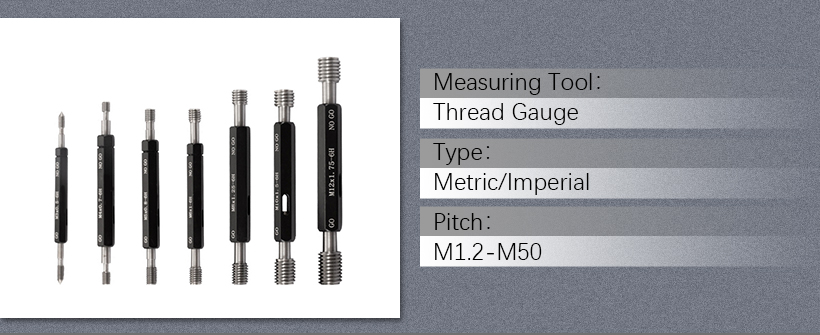

Thread Gauge A precision measuring tool used to inspect the pitch, angle, and form of a thread.It can be used to check both external and internal threads. |

Used to inspect the pitch, angle, and form of both internal and external threads.Used in manufacturing to ensure that threaded parts meet the required specifications. |

Radius and Diameter Measurement Tools

|

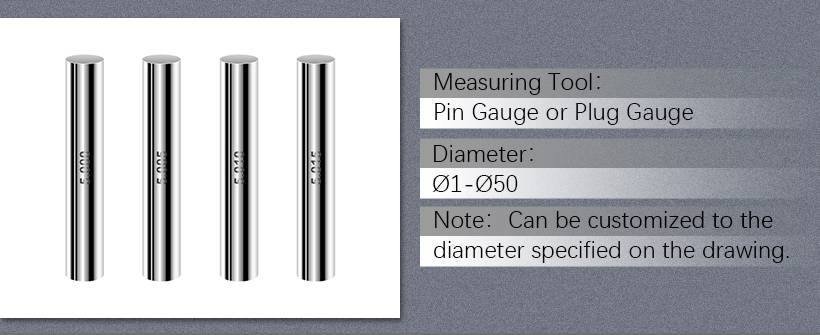

Pin Gauge A precision measuring tool used to verify the diameter of a hole.It's essentially a cylindrical pin with a very precise diameter. |

Used to accurately measure the diameter of holes.Widely used in quality control, assembly, and machining processes. |

|

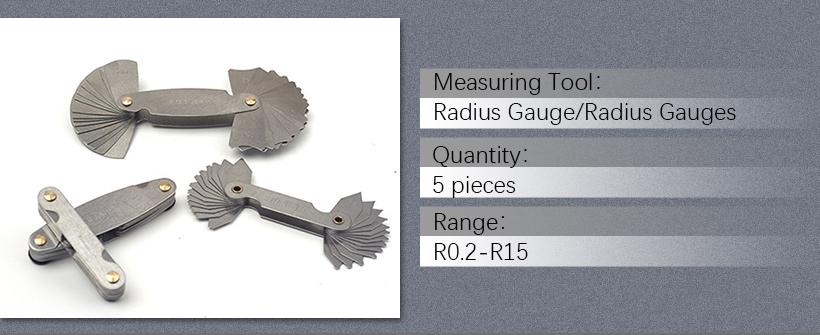

Radius Gauge A precision measuring tool used to measure the radius of a curved surface.It often comes in a set of different radii. |

Used to measure the radius of curved surfaces.Used in various industries, including manufacturing, automotive, and aerospace, to inspect the radii of curved components. |

Surface and Material Analysis Tools

|

Hardness Tester The device in the image is a Digital Micro Vickers Hardness Tester, also known as a Micro Vickers Hardness Tester. A hardness tester is a device used to determine the hardness of a material. |

Hardness is a measure of a material's resistance to permanent indentation. There are several different methods for measuring hardness, and the type of hardness tester used will depend on the material being tested and the desired level of precision. |

|

Roughness Tester A roughness tester, also known as a surface texture analyzer, is a precision instrument used to measure the surface roughness of a material. |

This measurement is crucial in various industries, including manufacturing, quality control, and research, as it directly impacts product performance, aesthetics, and durability. |

|

Metallographic Spectrum Analyzer A metallographic spectrum analyzer is an analytical instrument used to identify the elemental composition of a metal sample. |

It works by directing a beam of light at the metal sample, which excites the atoms in the sample and causes them to emit light at specific wavelengths. The emitted light is then analyzed by a spectrometer to determine the elements present in the sample and their concentrations. |

Machining Device

CNC Lathes: For turning and facing operations on cylindrical workpieces.

Turn-Mill Centers: For combined turning and milling operations, increasing efficiency and reducing setup times.

3-Axis and 4-Axis Milling Machines: For milling complex shapes and features on a variety of materials.

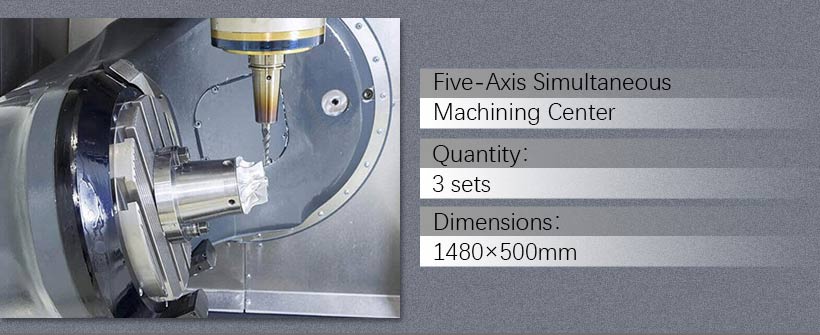

Five-Axis Simultaneous Machining Center: For highly complex parts requiring simultaneous control of five axes, achieving intricate geometries with precision.

Our capabilities include:

- Material versatility: We can work with a wide range of materials, including metals, plastics, and composites.

- Complex geometries: Our machines can handle intricate shapes and features, such as deep pockets, thin walls, and tight tolerances.

- High precision: We ensure precise measurements and tolerances using advanced metrology equipment.

- Custom solutions: We can tailor our services to meet your specific needs and requirements.

Industries we serve:

Contact us today to discuss your machining requirements and learn how we can help you achieve your goals.

![Aluminum 6061 vs 6063: Key Differences in CNC Aluminum Machining [2024 Guide] Aluminum 6061 vs 6063: Key Differences in CNC Aluminum Machining [2024 Guide]](/Uploads/news/677e3a8d147f1.jpg)